Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By 管理

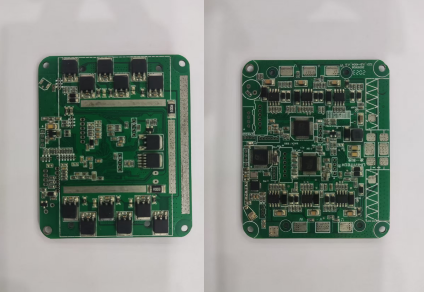

As an established PCBA manufacturer, LTPCBA is proud to introduce our latest high-density Control and Power Drive PCBA — a fully integrated solution engineered with intelligent layered design, functional zoning, and industrial-grade components. Designed to serve as the core control platform for demanding applications such as industrial automation, automotive systems, and advanced equipment, this PCBA delivers reliability, performance, and scalability.

Design & Layout: Layered Co-Design for Optimal Performance

Our PCBA is built around a multi-layer high-density PCB architecture that cleanly separates control and power functions:

Dedicated Functional Zones:

Control Layer (Top): Integrates high-performance ARM Cortex-M series MCUs, interface ICs, and signal conditioning circuitry. This layer handles real-time logic processing, multi-tasking, and industrial communication protocols.

Power Layer (Bottom): Hosts multiple industrial- and automotive-grade MOSFETs, supported by large-area copper plating and advanced thermal design. Ideal for high-current motor drive and power conversion applications.

Enhanced Signal Integrity & EMC Performance: Careful physical separation of power and control sections, combined with impedance-matched routing and optimized grounding, minimizes EMI and ensures stable control signal transmission. Fully compliant with industrial EMC standards.

High-Reliability Components for Demanding Environments

We select every component for endurance and precision:

Core Control Elements: ARM Cortex-M based MCUs capable of running advanced control algorithms including FOC for motors and battery management strategies.

Power Devices: Industrial- and automotive-grade MOSFETs with low RDS(on) and high breakdown voltage, supporting high-current outputs up to several tens of amps.

Passive Components: High-accuracy resistors and high-capacitance MLCCs rated for extended temperature ranges (-40°C to +125°C) and high-vibration environments.

Multi-Industry Applications: One Platform, Multiple Solutions

This integrated control and power drive PCBA enables precision logic and robust power delivery across multiple sectors:

Industrial Automation: Acts as a servo drive controller or industrial motor power module. Supports high-precision speed and torque control, along with industrial fieldbus protocols including CAN and EtherCAT. Ideal for robotic joints and automated production lines.

Automotive Electronics: Suitable for new energy vehicle BMS and motor drive control units. Enables accurate monitoring of voltage, current, and temperature, while ensuring efficient and safe power delivery — fully compliant with automotive reliability standards.

Advanced Equipment: Used in medical imaging drives and precision inspection instruments. Combines accurate control with stable power output to ensure high reliability in critical applications.

✅ Built for Reliability. Designed for Performance.

✅ Single-board integration reduces system complexity and development time

✅ Industrial and automotive-grade components ensure long-term reliability

✅ Layered PCB design improves thermal performance and signal integrity

-✅ Ready to deploy in automation, automotive, and medical applications

Ready to Power Your Next Innovation?

Simplify your design process and accelerate time-to-market with LTPCBA’s high-density Control & Power Drive PCBA.

Contact us today to request a custom sample or technical datasheet.

Visit our website to explore more smart PCBA solutions.

Do you have any questions, or would you like to speak directly with a representative?