News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

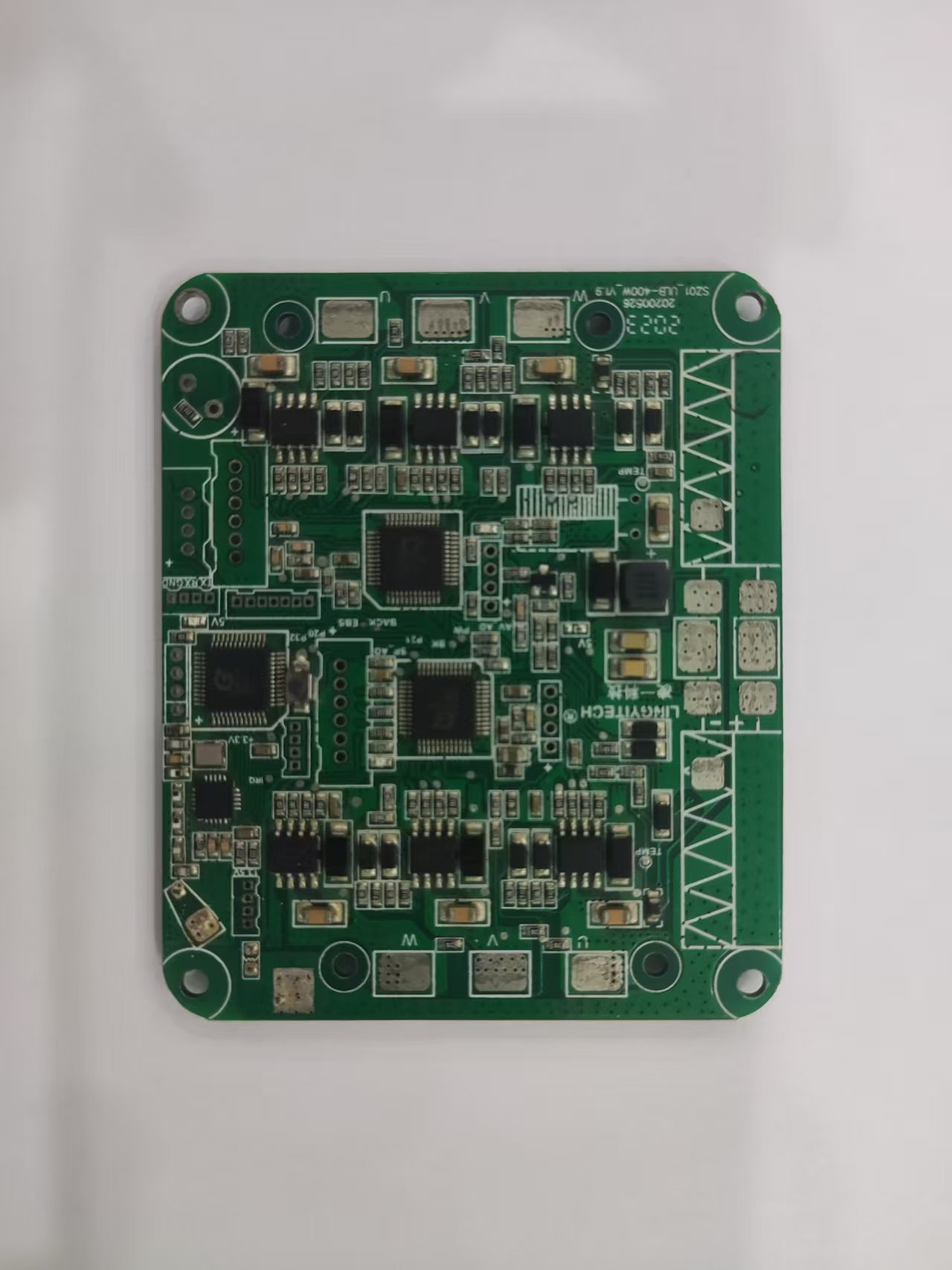

7 Steps to Master Quality Control in Professional PCBA Manufacturing

28 Jul, 2025

Achieving consistent quality in PCBA (Printed Circuit Board Assembly) manufacturing requires a systematic approach, integrating advanced technologies, strict protocols, and data-driven oversight. From design validation to final inspection, each step in the process plays a critical role in minimizing defects, ensuring reliability, and meeting industry standards. This guide outlines seven essential steps to implement robust… Continue reading 7 Steps to Master Quality Control in Professional PCBA Manufacturing

Learn More -

Through-Hole Technology vs. SMT: When to Choose Through-Hole for Electronics Manufacturing

28 Jul, 2025

In electronics manufacturing, selecting between Through-Hole Technology (THT) and Surface Mount Technology (SMT) depends on your project’s unique demands. While SMT dominates for compact, high-volume devices, through-hole technology remains irreplaceable for applications requiring exceptional durability, ease of repair, and reliability in harsh environments. This guide compares the two technologies and outlines scenarios where through-hole is… Continue reading Through-Hole Technology vs. SMT: When to Choose Through-Hole for Electronics Manufacturing

Learn More -

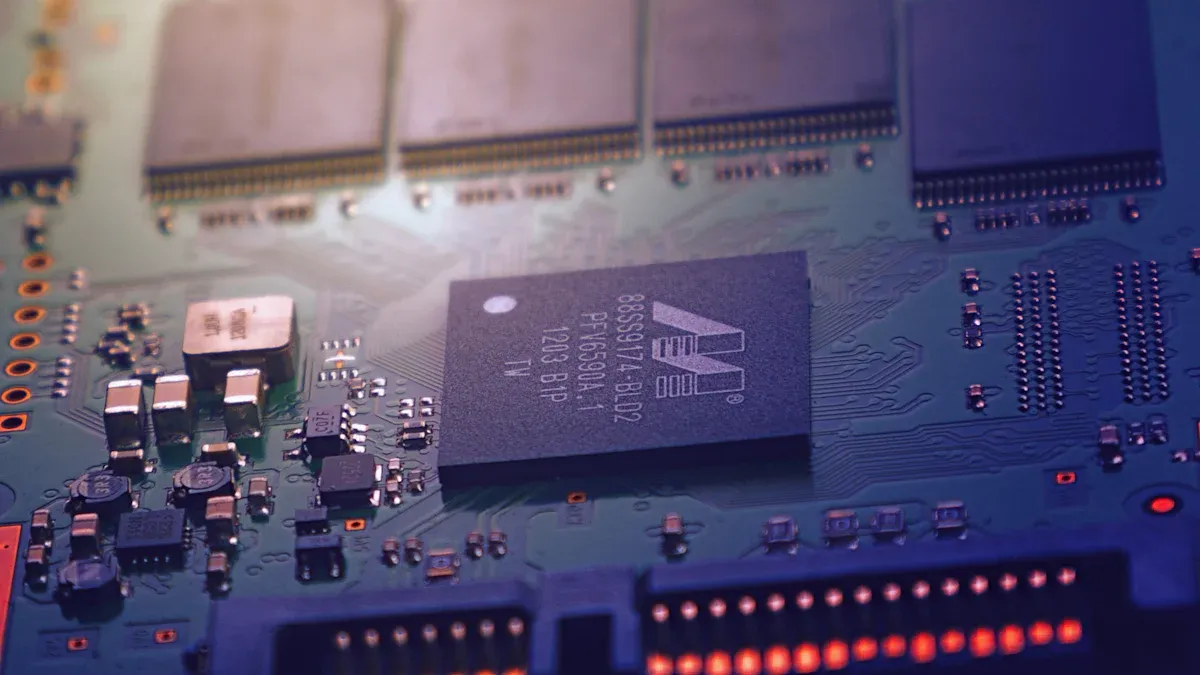

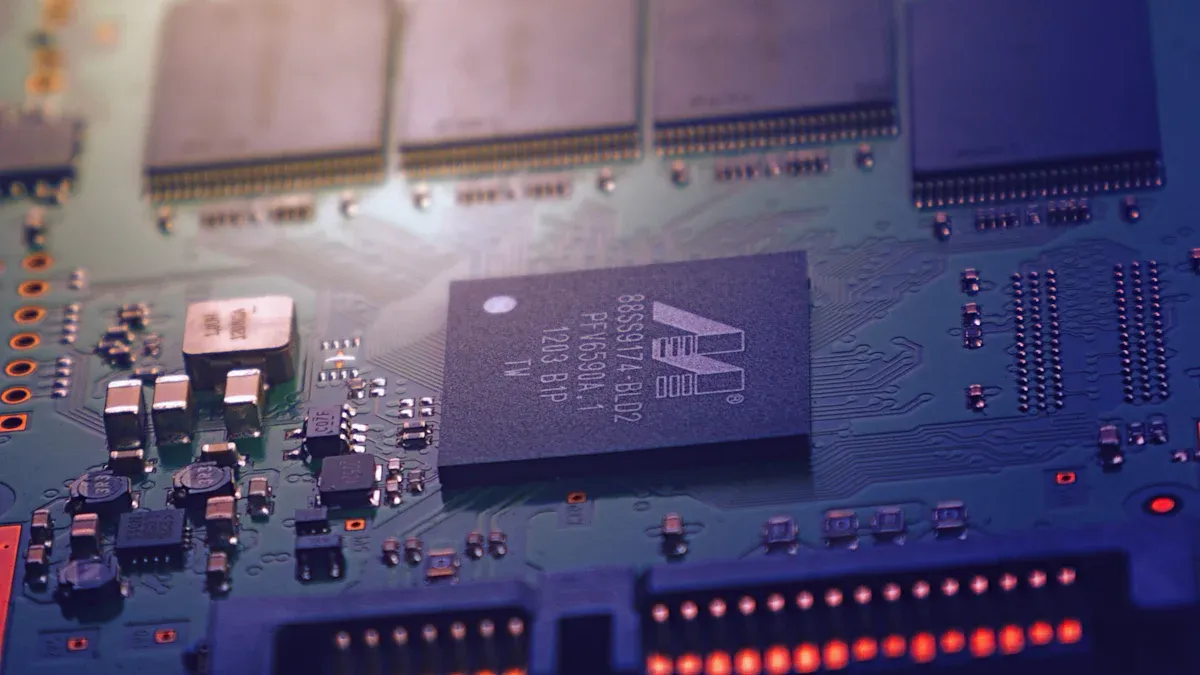

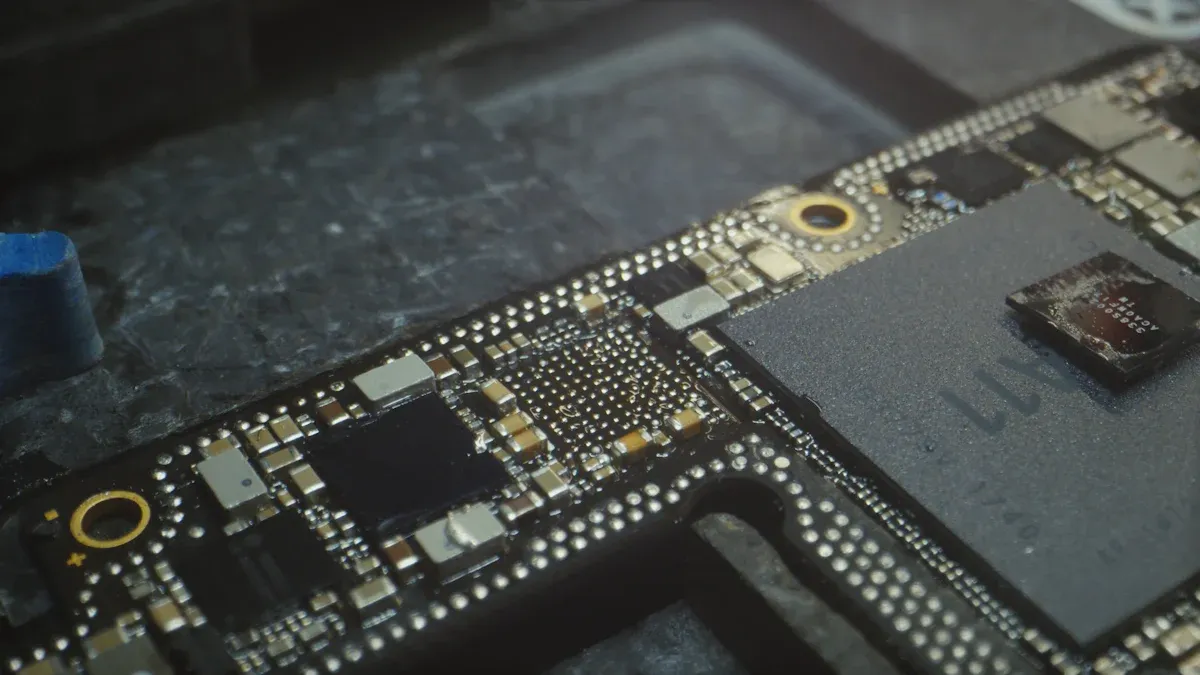

The Complete BGA Assembly Process: A Comprehensive Guide

25 Jul, 2025

Ball Grid Array (BGA) assembly is a precision-driven process critical to modern electronics manufacturing, enabling high-density connections in compact devices. From PCB design to rework, each step demands meticulous control to avoid hidden defects like “head-in-pillow” joints—costly to repair and challenging to detect. This guide breaks down the full BGA assembly workflow, highlighting best practices,… Continue reading The Complete BGA Assembly Process: A Comprehensive Guide

Learn More -

SMT Wave Soldering Quality: Key Factors, Common Defects, and Preventive Measures

25 Jul, 2025

Achieving consistent, high-quality solder joints in SMT wave soldering requires mastering a complex interplay of materials, design, process parameters, and equipment. Even minor deviations can lead to defects that compromise reliability, increase rework costs, and delay production. This guide explores the critical factors influencing wave soldering quality, identifies common defects, and outlines actionable preventive measures—drawing… Continue reading SMT Wave Soldering Quality: Key Factors, Common Defects, and Preventive Measures

Learn More -

Strategiesfor Preventing and Managing Lead Contamination in SMT Lead-Free Wave Soldering

25 Jul, 2025

In Surface Mount Technology (SMT) manufacturing, lead (Pb) contamination poses severe risks to product compliance, environmental safety, and human health. Lead-free wave soldering technology has emerged as a critical solution to mitigate these risks, combining specialized materials, strict process controls, and advanced quality management systems. This article details how to effectively prevent and control lead… Continue reading Strategiesfor Preventing and Managing Lead Contamination in SMT Lead-Free Wave Soldering

Learn More -

Key Parameters for Controlling SMT Wave Soldering Processes

24 Jul, 2025

Consistent quality in SMT wave soldering depends on precise control of every process step. Research shows that optimizing wave soldering parameters can rapidly reduce defect-related costs and improve PCB performance. LTPCBA leverages advanced technologies and strict protocols to manage temperatures, assembly sequences, and process variables, ensuring robust solder joints in every production run. Key Takeaways… Continue reading Key Parameters for Controlling SMT Wave Soldering Processes

Learn More