News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

A Comprehensive Guide to the PCBA Process: From Bare PCB to Functional Electronics

08 Sep, 2025

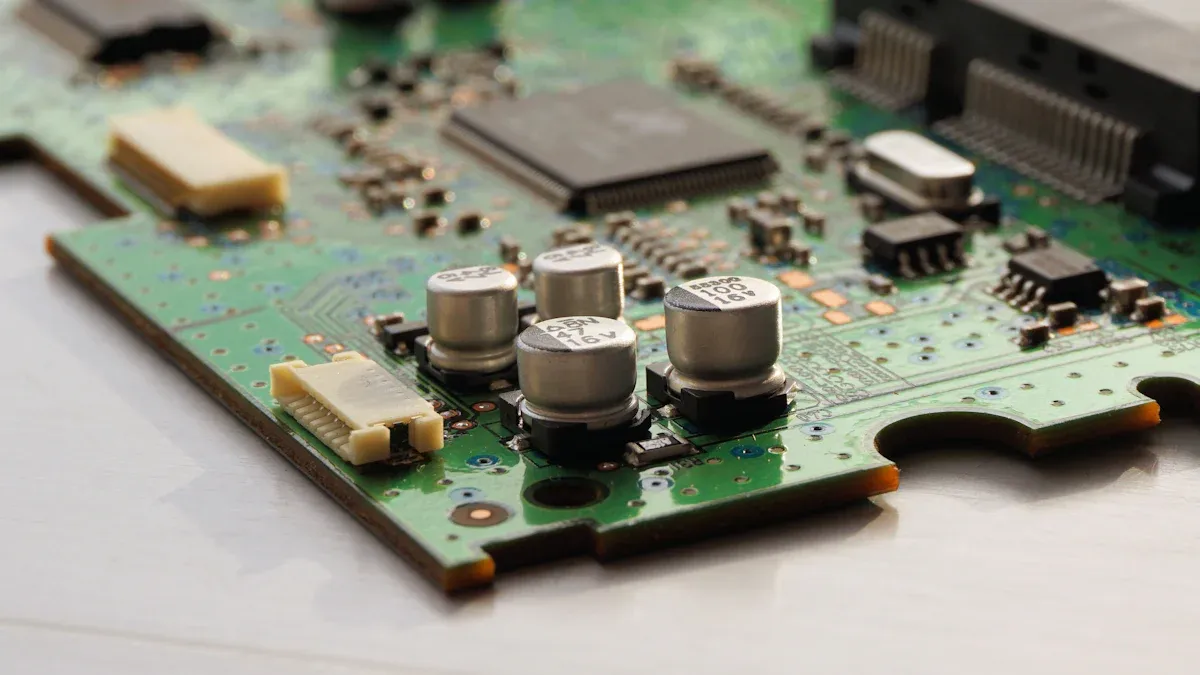

Printed Circuit Board Assembly (PCBA) is the backbone of modern electronics—powering everything from smartphones and wearables to automotive control systems and industrial machinery. This process transforms a plain, copper-traced PCB (Printed Circuit Board) into a fully operational device by precisely mounting, soldering, and testing electronic components. According to industry research, the global PCBA market exceeded… Continue reading A Comprehensive Guide to the PCBA Process: From Bare PCB to Functional Electronics

Learn More -

Essential Strategies to Mitigate Common Risks in PCBA Prototype Assembly

08 Sep, 2025

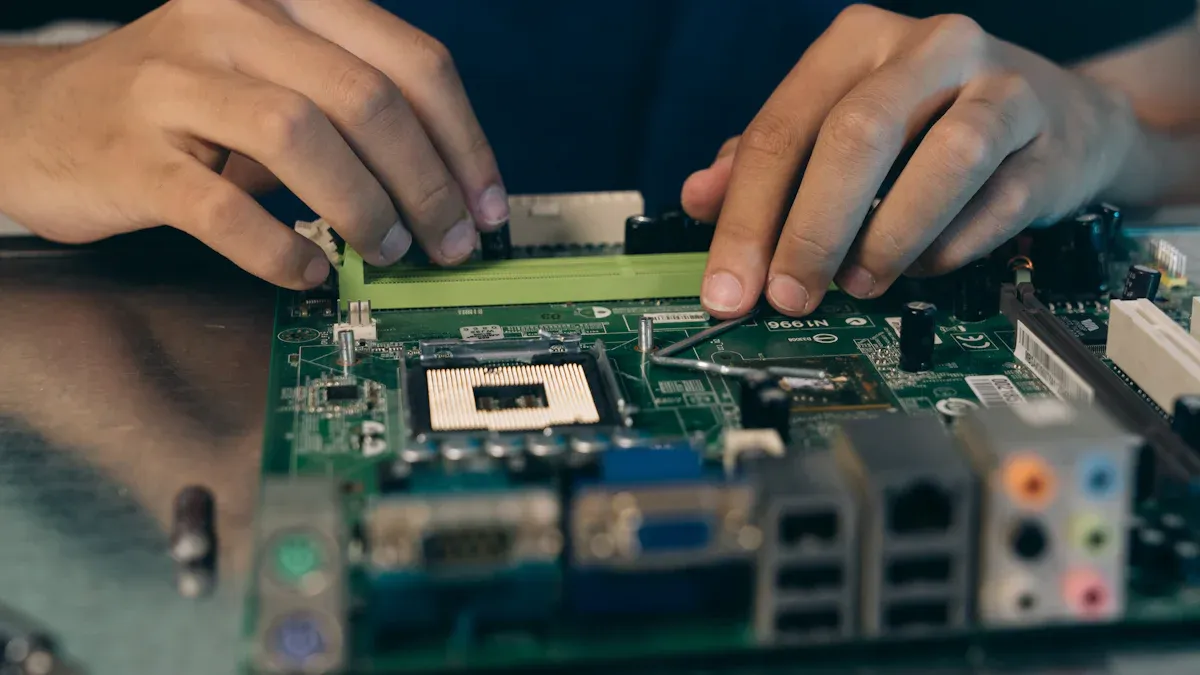

PCBA prototype assembly is a make-or-break phase for industrial and electronic product development—even small errors can lead to costly rework, project delays, or failed final products. From misaligned components to component shortages, manufacturers often face avoidable challenges that hinder efficiency and quality. By prioritizing proactive design checks, reliable component sourcing, and tight quality control, you… Continue reading Essential Strategies to Mitigate Common Risks in PCBA Prototype Assembly

Learn More -

Industrial Control Board PCBA Prototype Assembly: Success Stories & Proven Best Practices

08 Sep, 2025

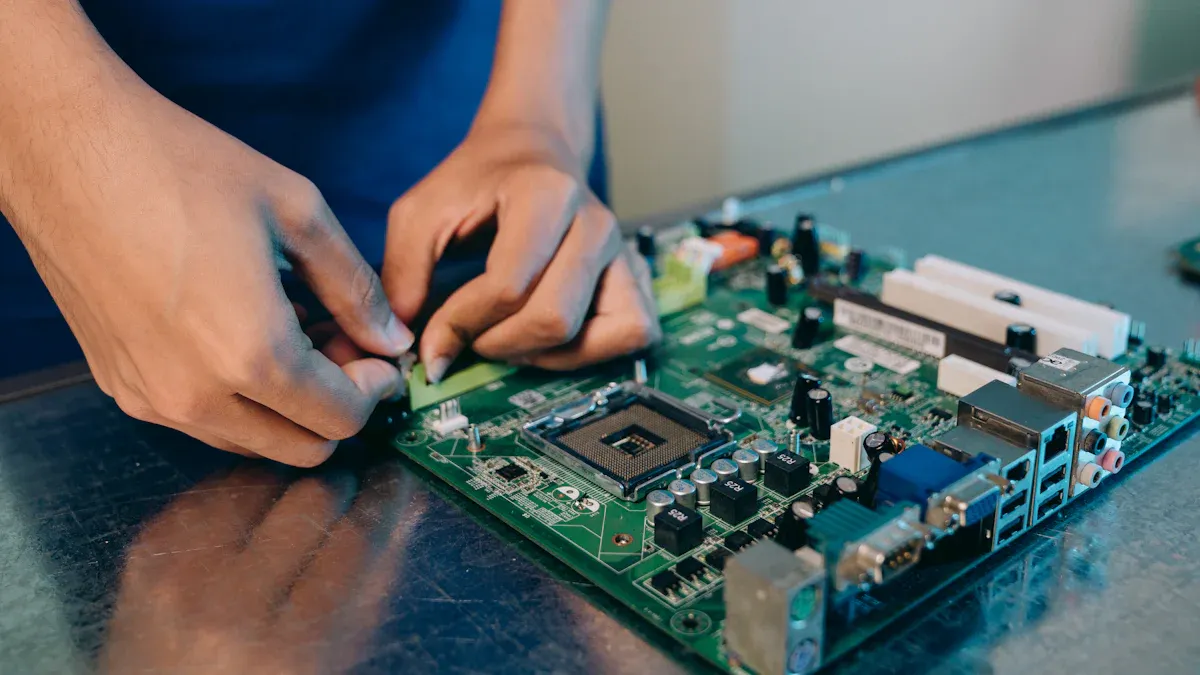

Industrial control boards serve as the “brain” of modern industrial systems, powering critical applications like PLCs (Programmable Logic Controllers), motor control units, and sensor-integrated machinery. The success of these systems hinges on PCBA prototype assembly—a phase that demands precision, rapid iteration, and strict quality control during early development. Manufacturers often grapple with challenges such as… Continue reading Industrial Control Board PCBA Prototype Assembly: Success Stories & Proven Best Practices

Learn More -

BGA Assembly: Key Challenges, Optimization Tips, and Best Practices

05 Sep, 2025

Ball Grid Array (BGA) assembly has become a cornerstone of modern electronics manufacturing, enabling compact, high-performance devices with dense connectivity. Unlike traditional leaded packages, BGAs use an array of solder balls beneath the component to connect to printed circuit boards (PCBs), offering superior signal integrity, heat dissipation, and space efficiency. However, mastering BGA assembly requires… Continue reading BGA Assembly: Key Challenges, Optimization Tips, and Best Practices

Learn More -

Wave Soldering in DIP Assembly: Essential Technical Requirements and Best Practices

05 Sep, 2025

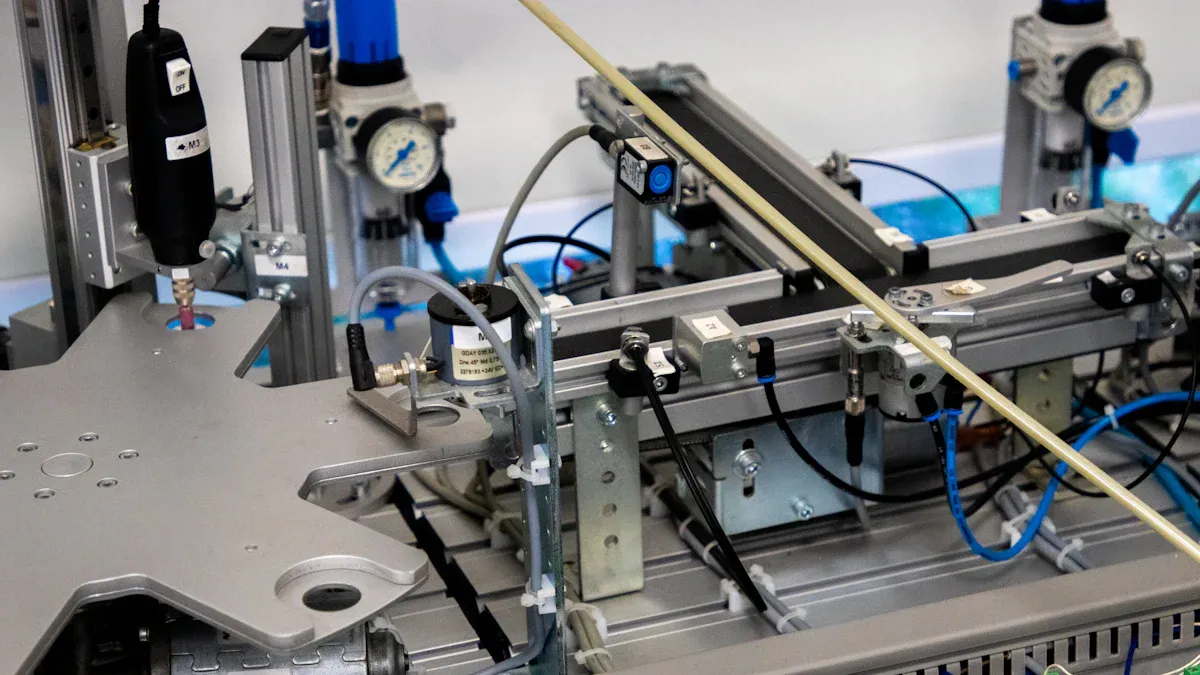

Wave soldering is a cornerstone of Dual In-Line Package (DIP) assembly, enabling efficient, high-volume production of reliable electronic circuits. By passing printed circuit boards (PCBs) over a wave of molten solder, this process creates strong electrical and mechanical bonds between DIP components and PCB pads. However, achieving consistent, high-quality results requires strict adherence to technical… Continue reading Wave Soldering in DIP Assembly: Essential Technical Requirements and Best Practices

Learn More -

Lead-Free Solder Paste in SMT Assembly: When to Choose It and Best Practices for Success

05 Sep, 2025

In the fast-paced world of electronics manufacturing, the shift toward sustainable and safe practices has made lead-free solder paste a cornerstone of modern Surface Mount Technology (SMT) assembly. Driven by global regulations, environmental concerns, and consumer demand for safer products, lead-free solder paste has replaced traditional lead-based options in most applications. But when should you… Continue reading Lead-Free Solder Paste in SMT Assembly: When to Choose It and Best Practices for Success

Learn More