News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

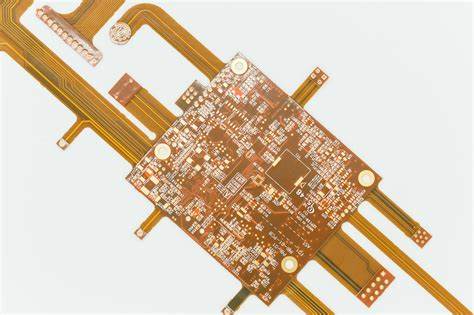

Issues to Be Noted in the SMT Assembly of Rigid-Flex PCBs

12 Jun, 2025

Key Takeaways Common Challenges in SMT Assembly for Rigid-Flex PCBs Warping and Flexing During Assembly Component Placement Accuracy Method Purpose AOI Surface defect detection X-ray Inspection Hidden joint analysis (BGA/CSP) Thermal Stress and Heat Management Test Type Objective Thermal Shock Evaluate resistance to rapid temp changes Burn-in Testing Identify early failures under prolonged heat Solder… Continue reading Issues to Be Noted in the SMT Assembly of Rigid-Flex PCBs

Learn More -

Mastering DIP Assembly and Through-Hole Tolerances

12 Jun, 2025

Key Takeaways Understanding DIP Assembly Technology What Is DIP Assembly Technology? DIP (Dual In-Line Package) assembly attaches components to PCBs via two rows of pins inserted through drilled holes. Key features include: Applications in Electronics Manufacturing Sector Use Case Examples Prototyping Easy component replacement for testing Aerospace & Military High-reliability components for harsh environments Education… Continue reading Mastering DIP Assembly and Through-Hole Tolerances

Learn More -

Key Points of DIP Assembly Technology

12 Jun, 2025

Key Takeaways Key Components of DIP Assembly Technology Dual In-Line Packages (DIP) DIPs are rectangular components with two rows of pins, available in materials like: Material Type Features Copper Alloy Excellent conductivity, thermal management, and mechanical strength. Iron-Nickel Alloy (Alloy 42) Low thermal expansion, heat stability, moderate conductivity. Copper-Molybdenum/Cu-W Superior thermal conductivity for high-power applications.… Continue reading Key Points of DIP Assembly Technology

Learn More -

How to Clean the PCB Board After SMT Assembly

11 Jun, 2025

Key Takeaways Why It’s Important to Clean the PCB Board After SMT Assembly Preventing Corrosion and Long-Term Damage Ensuring Optimal Electrical Performance Cleaning Method Contaminants Removed Performance Impact Engineered PCB Solutions Flux residues Enhances reliability in critical applications High-precision methods Microscopic particles Improves conductivity and stability Enhancing Product Reliability Effective Methods to Clean the PCB… Continue reading How to Clean the PCB Board After SMT Assembly

Learn More -

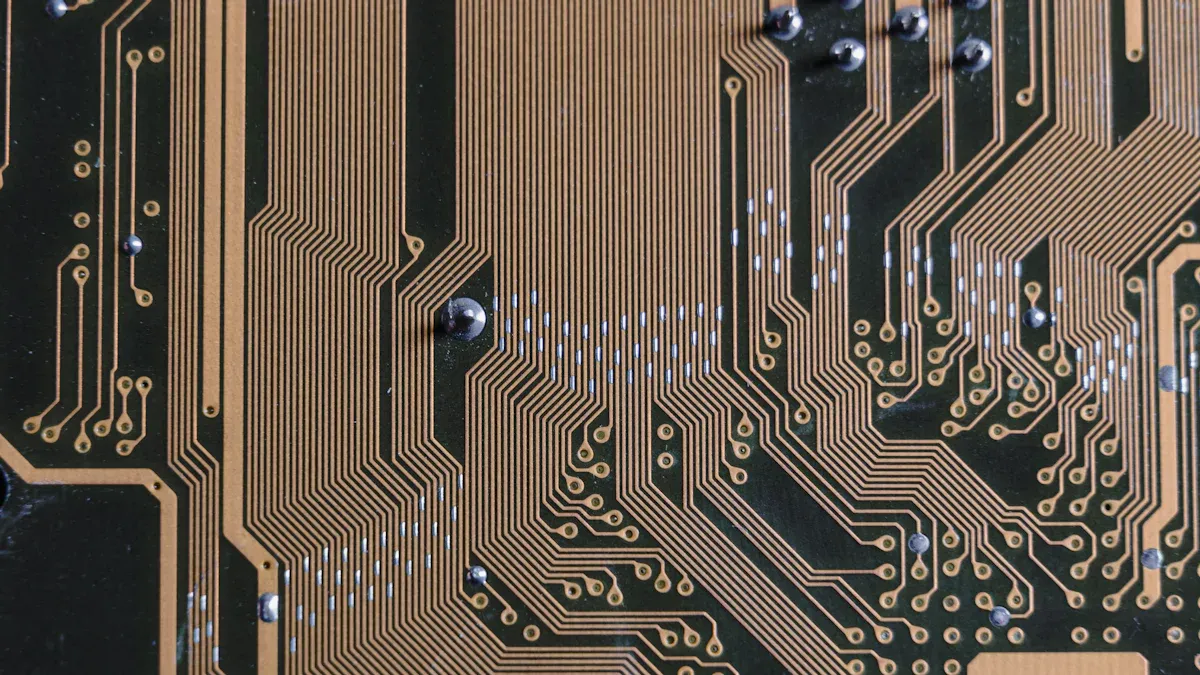

Technical Precautions for HDI PCB Surface Mount Assembly

11 Jun, 2025

Key Takeaways Common Challenges in HDI PCB Surface Mount Assembly Smaller Components and Tight Spacing Report Title Summary Area Array Placement Yield Prediction Analyzes placement challenges for miniature components. Warpage Modeling And Measurement Links component size to assembly reliability issues. Thermal Control During Soldering Material Selection Complexity Metric Impact on HDI PCBs Glass Transition Temperature… Continue reading Technical Precautions for HDI PCB Surface Mount Assembly

Learn More -

The Main Production Materials Needed for PCBA Production

11 Jun, 2025

Key Takeaways Substrates and Copper Foils: Key Materials for PCBA Substrates: The Base of PCBs Substrates serve as the foundational layer of PCBs, providing mechanical support and dimensional stability. Common materials include: Advanced Packaging Applications: Copper Foils: Layers for Electricity Flow Copper foils create conductive traces on PCBs, chosen for their excellent conductivity and affordability.… Continue reading The Main Production Materials Needed for PCBA Production

Learn More