News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

The Significance of Nitrogen Reflow Soldering for Automotive SMT Products and Other PCBA Products

11 Jun, 2025

Key Takeaways Understanding Nitrogen Reflow Soldering What Is Nitrogen Reflow Soldering? Nitrogen reflow soldering is a process that uses inert nitrogen gas in a reflow oven to: How Does Nitrogen Improve Soldering Quality? Benefits for Automotive SMT Products Improved Reliability for Car Electronics Reduced Soldering Defects Performance in Harsh Environments Advantages for Other PCBA Products… Continue reading The Significance of Nitrogen Reflow Soldering for Automotive SMT Products and Other PCBA Products

Learn More -

How to Select a PCBA Supplier That Meets Your Needs

11 Jun, 2025

Key Takeaways Quality and Certifications Why Quality Standards Matter Key Certifications Certification Focus Area ISO 9001:2015 Quality management systems ISO 13485:2016 Medical device manufacturing LTPCBA’s Quality Approach Manufacturing Capabilities and Technology Equipment and Expertise Capability LTPCBA’s Performance Monthly PCB capacity 60,000 sq.m SMT monthly capacity 240 million points Precision Handles 0.25mm pitch components Technology Matching… Continue reading How to Select a PCBA Supplier That Meets Your Needs

Learn More -

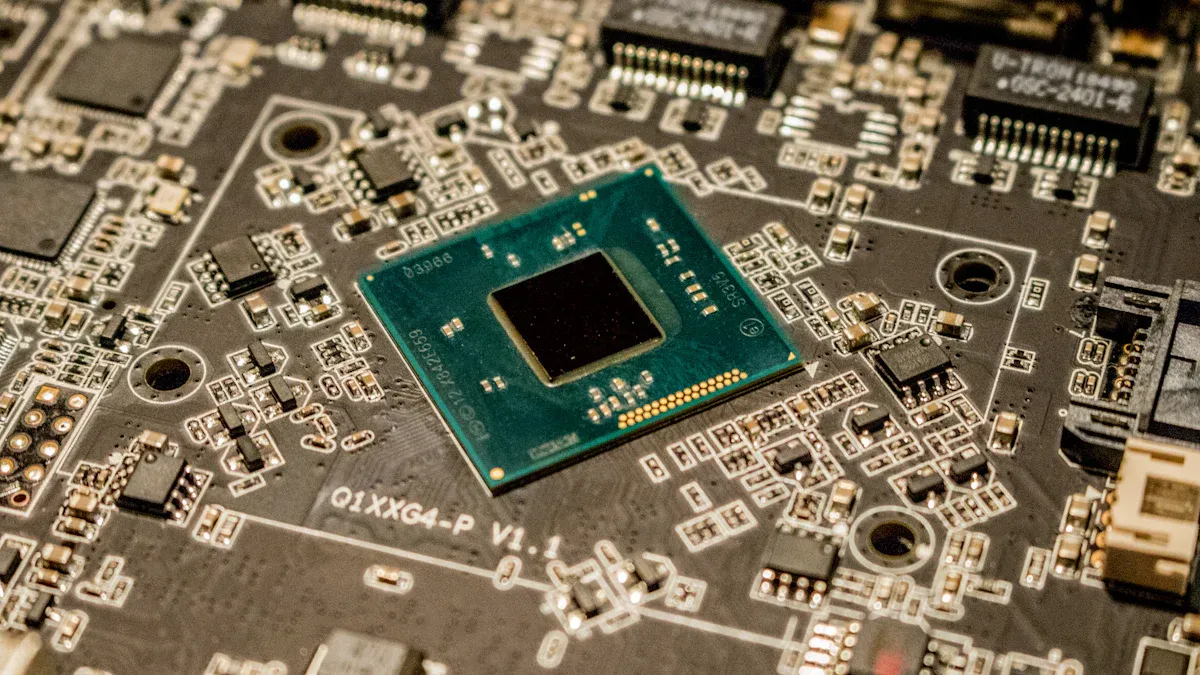

What is PCBA and Its Components

11 Jun, 2025

Key Takeaways Understanding PCBA What Is PCBA? PCBA is a PCB with components soldered onto it, forming a working electronic circuit. It adheres to standards like IPC-A-610, which defines: Criteria Type Description Accept Criterion Grades assembly conditions (good, marginal, defective) Welding Requirements Specifies soldering methods and quality thresholds Why Is PCBA Essential? Industry Applications Industry… Continue reading What is PCBA and Its Components

Learn More -

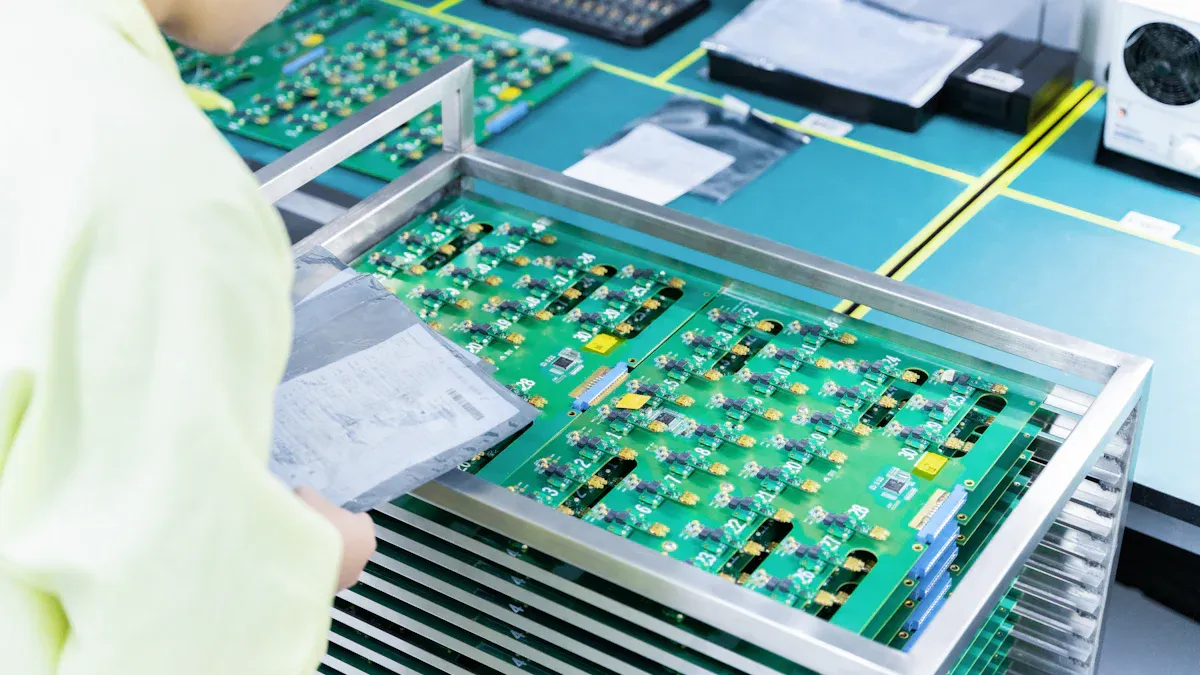

The Selection of PCB Board Materials in SMT Assembly

11 Jun, 2025

Key Takeaways Key Factors in Picking PCB Board Materials Heat Management Signal Integrity Cost-Quality Balance PCB Type Price Range Suitability SMT 50–500 per panel High-volume, cost-effective Through-Hole Higher labor costs Rugged, high-power designs Manufacturing Compatibility Factor Impact on Production Layer count Affects drilling and lamination Trace width Determines current carrying capacity Environmental Compliance Regulation Material… Continue reading The Selection of PCB Board Materials in SMT Assembly

Learn More -

The Basic Requirements for PCB Boards in SMT Production

10 Jun, 2025

Key Takeaways PCB Design Needs for SMT Production Even Component Placement Heat Management Soldering-Friendly Layout Material Selection & Thickness Aspect Considerations Material FR-4 for cost-performance balance; high-Dk materials for high-frequency circuits. Thickness 0.8–1.6mm standard; thicker boards (2.0mm) for heavy components. Trade-off Thin boards excel in signal integrity; thick boards offer better thermal dissipation. Component Placement… Continue reading The Basic Requirements for PCB Boards in SMT Production

Learn More -

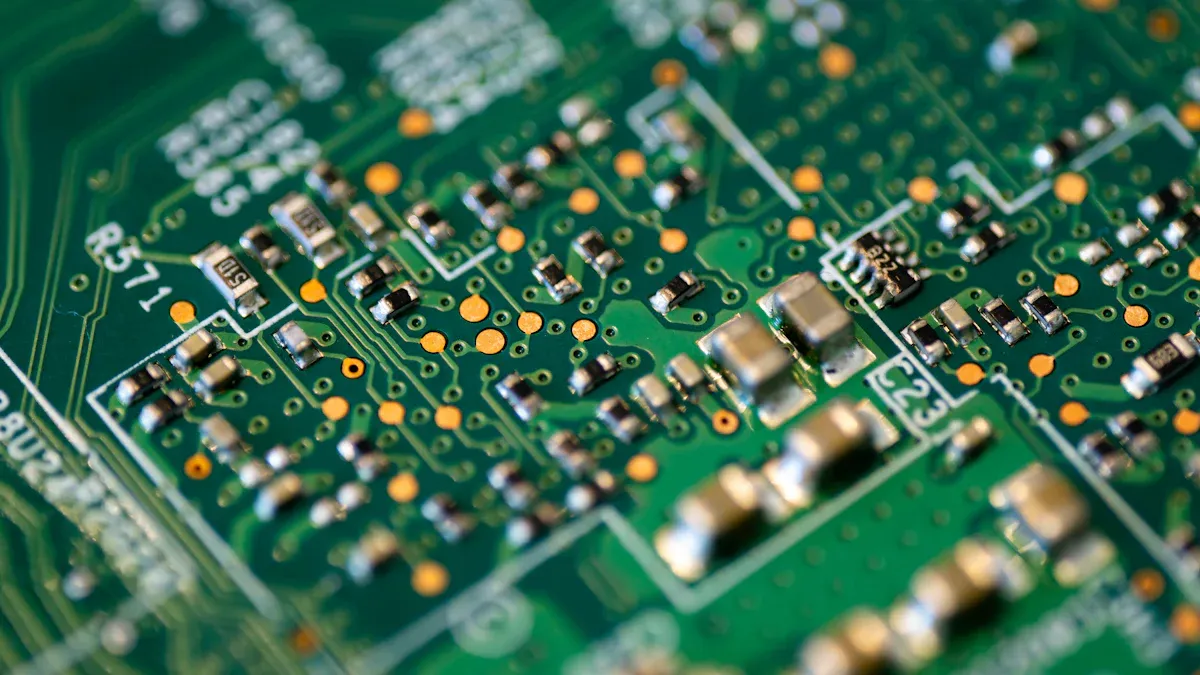

The Welded End Structures of SMC and SMD

10 Jun, 2025

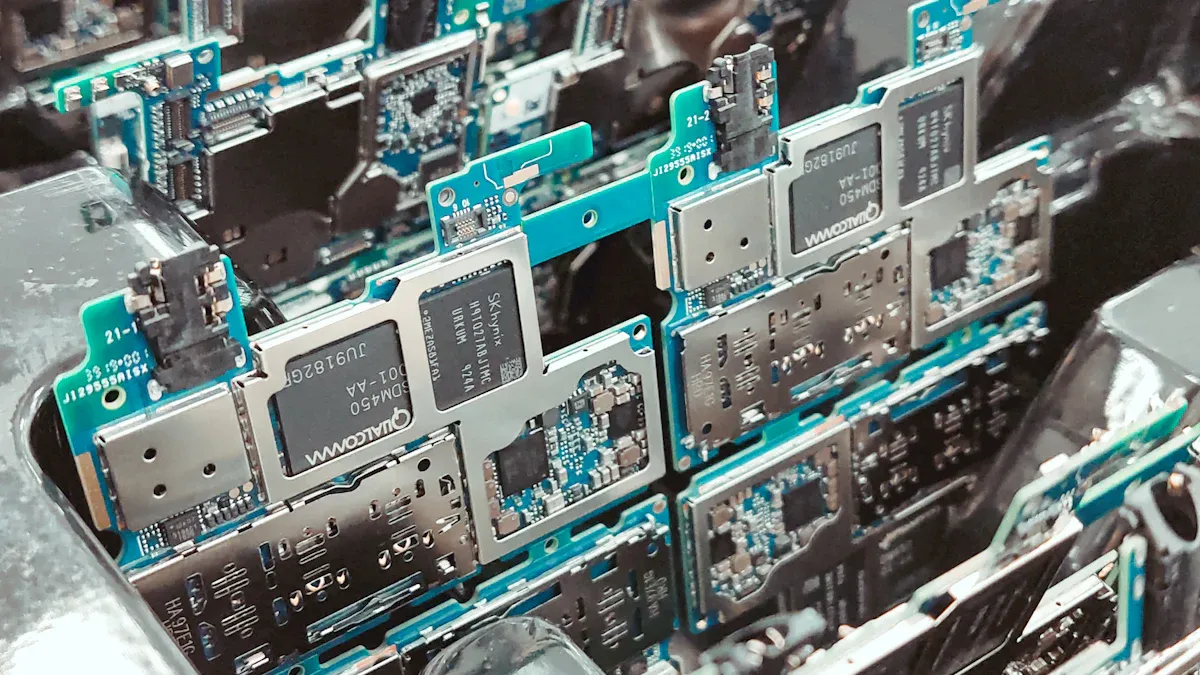

Key Takeaways Understanding SMC and SMD What Is SMC? SMC (Surface-Mount Components) are miniature electronic parts attached directly to PCB surfaces. Examples include resistors, capacitors, and diodes. Their small size makes them ideal for space-constrained devices like smartphones and tablets. What Is SMD? SMD (Surface-Mount Devices) are integrated modules combining multiple components. They are larger… Continue reading The Welded End Structures of SMC and SMD

Learn More