News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

Understanding the Pros and Cons of SMD and Through-Hole Technology

10 Jun, 2025

CONTENTS Key Takeaways Advantages of Surface Mount Technology Small Size and Lightweight Design SMT places components directly on the PCB surface, eliminating the need for drilled holes. This allows: Fast Assembly with Automation Automated SMT systems enable high-volume production: Metric Value Market Share (2023) 46.66% Market Value USD 2,707.03 Million Projected CAGR 8.50% Cost Efficiency… Continue reading Understanding the Pros and Cons of SMD and Through-Hole Technology

Learn More -

SMT and DIP Assembly Explained for PCBA Applications

10 Jun, 2025

CONTENTS Key Takeaways Understanding DIP Assembly in PCBA How DIP Assembly Works DIP (Dual In-line Package) uses components with two rows of pins inserted into pre-drilled PCB holes. Key steps include: Wave soldering is critical for durable joints, making DIP suitable for high-stress environments. Advantages of DIP Assembly Disadvantages of DIP Assembly Exploring SMT Assembly for… Continue reading SMT and DIP Assembly Explained for PCBA Applications

Learn More -

What Is Full Turn-Key PCB Manufacturing and Assembly

10 Jun, 2025

CONTENTS Key Takeaways What Does a Full Turn-Key PCB Manufacturer Offer? PCB Design and Prototyping Quality Assurance Steps: Evidence Type Description Data Collection Monitor critical dimensions post-production Process Capability Studies Analyze tool wear and operator impact Continuous Improvement Refine tolerances with manufacturing feedback Component Sourcing and Procurement PCB Fabrication and Assembly Turnkey vs. Traditional Processes:… Continue reading What Is Full Turn-Key PCB Manufacturing and Assembly

Learn More -

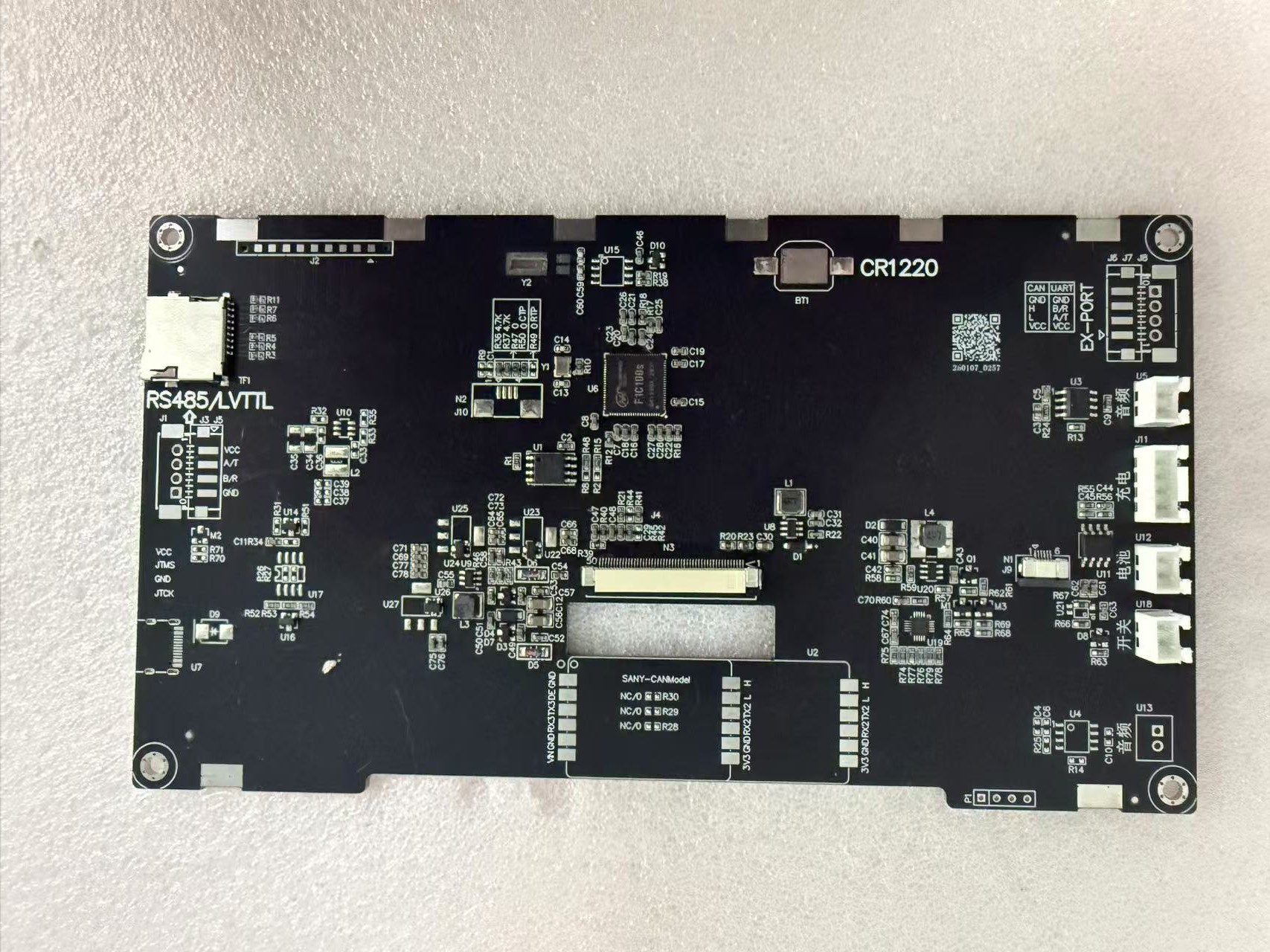

Understanding Industrial Serial Screen PCBA in Modern Industries

06 Jun, 2025

Understanding Industrial Serial Screen PCBA in Modern Industries CONTENTS Key Takeaways What is Industrial Serial Screen PCBA? Definition and Core Features Industrial serial screen PCBA is a specialized printed circuit board assembly designed for industrial environments, enabling reliable serial communication between devices. Key features include: Technical Specifications: Feature Specification PCB Type Multilayer Cu (2–3 oz)… Continue reading Understanding Industrial Serial Screen PCBA in Modern Industries

Learn More -

How Quick-Turn PCB Assembly Prototypes Drive Project Efficiency

06 Jun, 2025

How Quick-Turn PCB Assembly Prototypes Drive Project Efficiency CONTENTS Key Takeaways Understanding Quick-Turn PCB Prototypes What Are Quick-Turn PCB Prototypes? Quick-turn PCB prototypes are rapidly fabricated circuit boards designed for fast design validation and iteration. Unlike traditional methods, they prioritize speed while maintaining quality, ideal for industries like electronics, healthcare, and telecommunications. Why Quick-Turn Prototypes… Continue reading How Quick-Turn PCB Assembly Prototypes Drive Project Efficiency

Learn More -

Reflow Soldering Temperature Zones: Key to PCB Quality in SMT Assembly

22 May, 2025

In Surface Mount Technology (SMT) assembly, reflow soldering is a critical process that determines the reliability of PCB connections. At LTPCBA, we specialize in optimizing reflow temperature zones to ensure consistent, high-quality solder joints. This article explores the science behind each temperature zone, their impact on PCB quality, and best practices for achieving superior results. Key Takeaways… Continue reading Reflow Soldering Temperature Zones: Key to PCB Quality in SMT Assembly

Learn More