News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

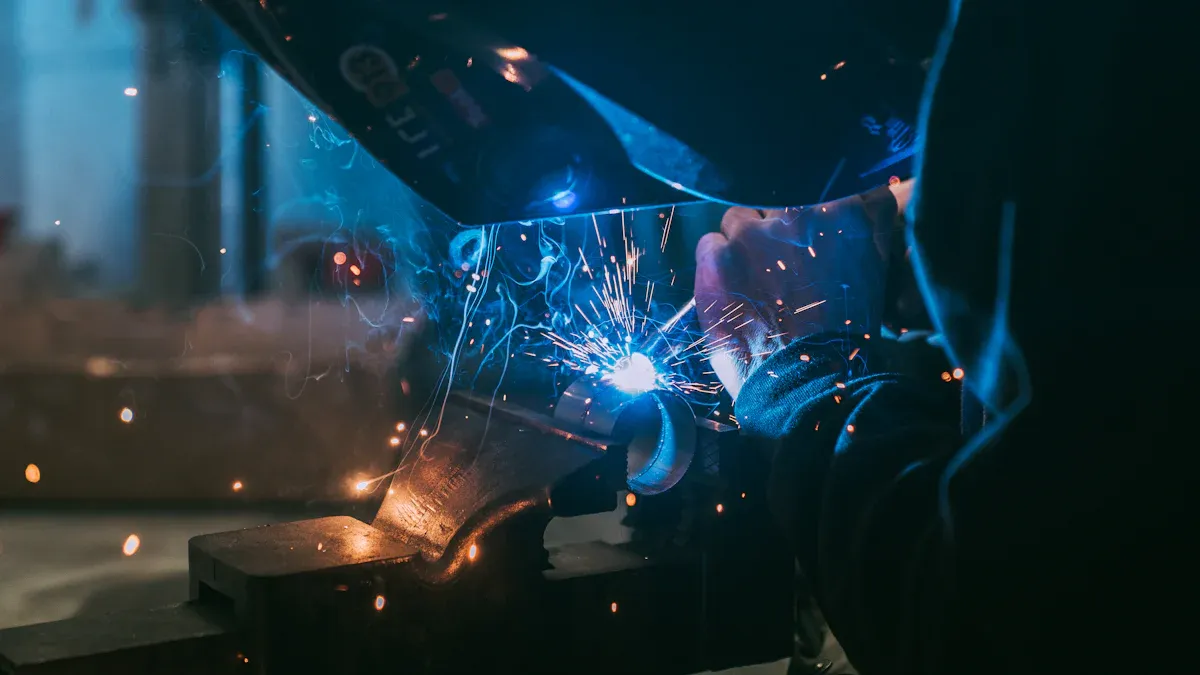

SMC vs. SMD Welded End Structures: Design, Performance, and Applications in Electronics

21 Aug, 2025

Welded end structures are the unsung heroes of modern electronics, serving as the critical link between surface-mount components (SMCs), surface-mount devices (SMDs), and printed circuit boards (PCBs). These structures ensure mechanical stability, reliable electrical conductivity, and long-term durability—qualities that directly impact a device’s performance and lifespan. Whether in a smartphone’s tiny resistors or industrial sensors,… Continue reading SMC vs. SMD Welded End Structures: Design, Performance, and Applications in Electronics

Learn More -

Ordinary AOI vs. Online AOI: Choosing the Right Inspection System for SMT Assembly

21 Aug, 2025

In the fast-paced world of Surface Mount Technology (SMT) assembly, ensuring PCB quality is non-negotiable. Automated Optical Inspection (AOI) systems have become indispensable tools for detecting defects, but not all AOI solutions are created equal. Ordinary (offline) AOI and online AOI serve distinct purposes, each with unique strengths and limitations. As the global AOI market… Continue reading Ordinary AOI vs. Online AOI: Choosing the Right Inspection System for SMT Assembly

Learn More -

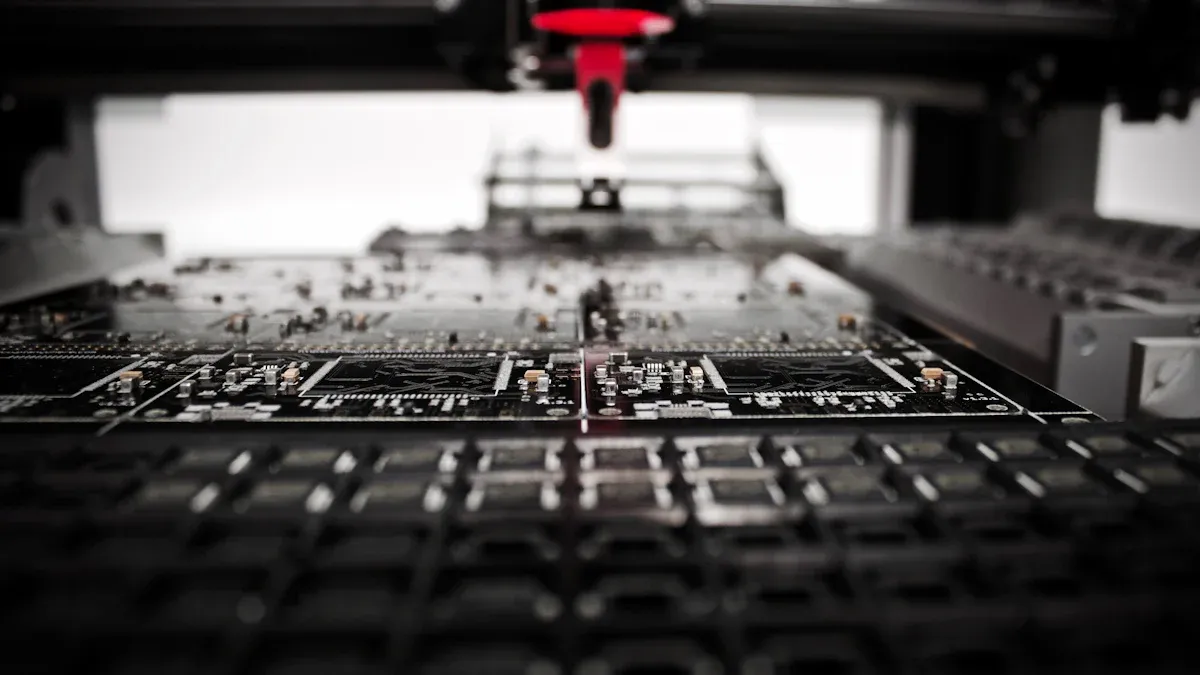

SMT Line Optimization: Elevating PCBA Manufacturing Efficiency and Quality

21 Aug, 2025

In the fast-paced world of electronics manufacturing, optimizing Surface Mount Technology (SMT) lines is no longer optional—it’s a necessity to stay competitive. SMT line optimization transforms production by reducing waste, accelerating throughput, and enhancing product reliability. Leading manufacturers achieve Overall Equipment Effectiveness (OEE) rates above 85%, cut labor costs by 40%, and boost first-pass yields… Continue reading SMT Line Optimization: Elevating PCBA Manufacturing Efficiency and Quality

Learn More -

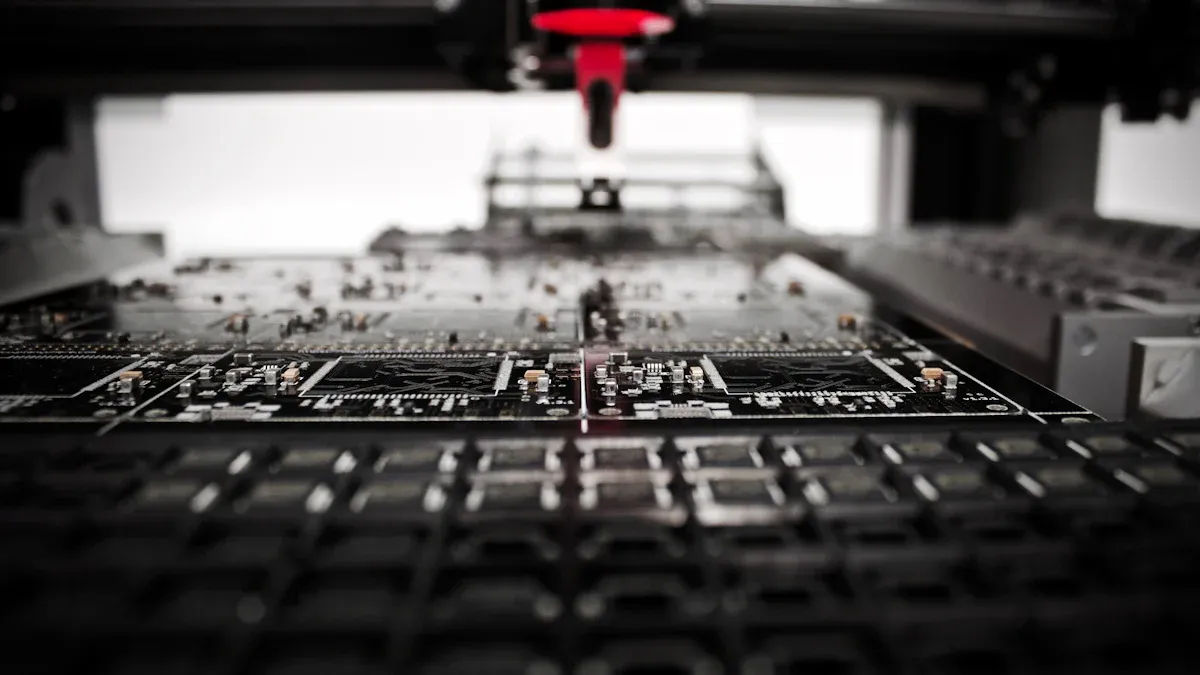

SPI Visual Inspection in PCBA Production: Boosting Quality Post-SMT Solder Paste Printing

20 Aug, 2025

In the intricate world of PCBA (Printed Circuit Board Assembly) manufacturing, the quality of solder paste application directly determines the reliability of the final product. Solder Paste Inspection (SPI) has emerged as a critical technology in this process, acting as a safeguard to ensure solder paste deposits meet precise standards after screen printing. By catching… Continue reading SPI Visual Inspection in PCBA Production: Boosting Quality Post-SMT Solder Paste Printing

Learn More -

Solder Paste Printing Quality Control in SMT Production: Essential Strategies for Defect-Free Assembly

20 Aug, 2025

Solder paste printing is the cornerstone of successful surface mount technology (SMT) production, serving as the critical link between PCB design and reliable component attachment. Research indicates that over 60% of soldering defects in SMT assemblies originate during the printing process, making quality control in this stage paramount for reducing rework, lowering costs, and ensuring… Continue reading Solder Paste Printing Quality Control in SMT Production: Essential Strategies for Defect-Free Assembly

Learn More -

Solder Paste Quality: Critical Factors Shaping SMT Soldering Success in PCB Assembly

20 Aug, 2025

In surface mount technology (SMT) assembly, solder paste acts as the unsung hero that bridges components to printed circuit boards (PCBs). Its quality directly influences solder joint strength, PCB reliability, and long-term performance of electronic devices. Studies show that a staggering 90% of soldering defects originate during the solder paste printing stage—making paste quality a… Continue reading Solder Paste Quality: Critical Factors Shaping SMT Soldering Success in PCB Assembly

Learn More