Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By 管理

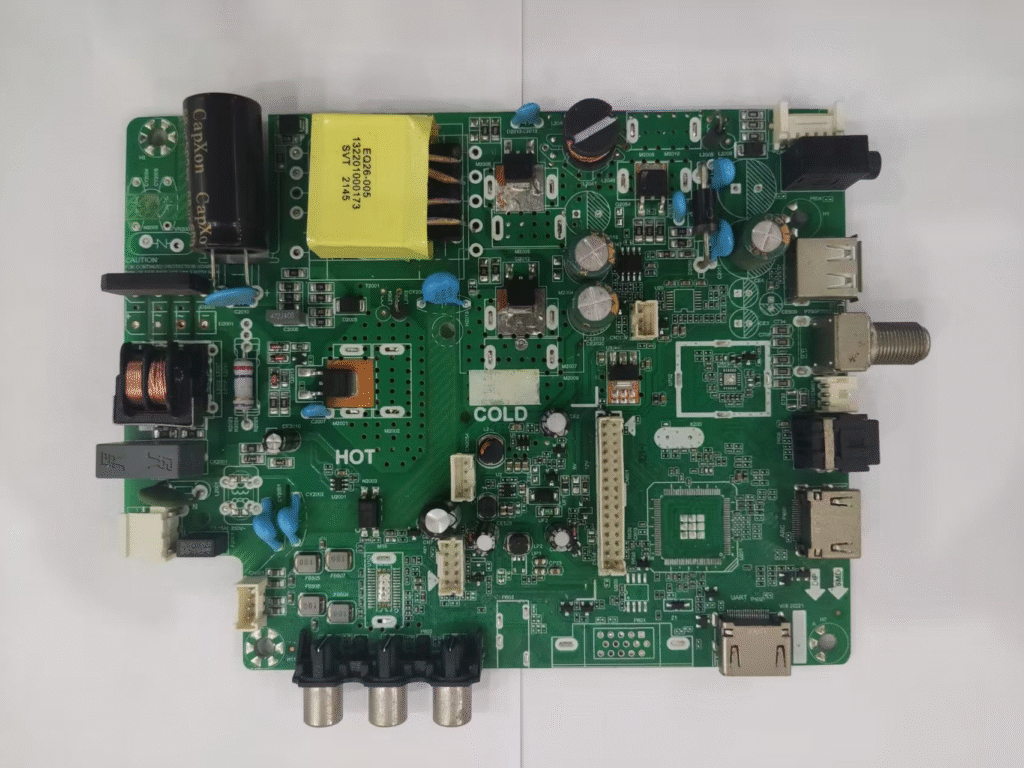

Amid the growing trends of smart and compact home appliances, the integration level and reliability of LCD TV mainboards have become pivotal to overall system performance. This analysis examines a typical All-in-One LCD TV Mainboard—integrating driver, power supply, and signal processing functions—to dissect its technical features and manufacturing processes, while showcasing LTPCBA’s expertise in home appliance electronics manufacturing.

Integrated Design: Synergistic Innovation Across Three Core Modules

1. Signal Processing Module: Comprehensive Interface Compatibility

– Integrates multiple interface standards including HDMI, USB, RF, and AV, supporting peripheral inputs from set-top boxes, USB drives, and gaming consoles

– Incorporates advanced video decoding and enhancement chips to deliver high-definition rendering with synchronized audio-video performance, meeting demanding home entertainment and interactive gaming requirements

2. Power Management Module: Optimized Zoning for Enhanced Safety

– Implements isolated “hot/cold zone” layout with physical separation between high-voltage components (transformers, inductors) and low-voltage control circuits, significantly improving safety and EMI immunity

– Utilizes low-loss capacitors (e.g., CapXon) and high-efficiency transformers, achieving >85% power conversion efficiency suitable for extended operational cycles

3. Driver Control Module: Intelligent System Core

– Main processor integrates logic control circuits handling system commands, interface rendering, and hardware driving functions

– Strategic placement away from high-voltage zones, complemented by impedance matching and shielding for optimal signal integrity

Modular Architecture: Balancing Standardization with Flexibility

Centralized Interface Organization: Zoned interface arrangement enables quick cable management and serviceability

Thermal Management Optimization: Distributed placement of high-power components combined with strategic PCB cutouts and thermal interface materials effectively controls temperature rise

Cross-Model Compatibility: Universal circuit architecture supports 32-42 inch LCD panel configurations, reducing development costs for manufacturers

LTPCBA Manufacturing Excellence: Engineering Reliability into Every Product

With two decades of specialized experience in SMT electronics manufacturing, LTPCBA has achieved significant manufacturing breakthroughs in high-volume mainboard production:

1. Hybrid Assembly Technology: Precision Meets Durability

– Automated SMT Placement: ±0.03mm placement accuracy for fine-pitch components with solder paste deposition variation under 10%

– Selective Wave Soldering: Precision soldering for through-hole components (transformers, large inductors) eliminating cold joints and bridging defects

2. Quality Assurance: Comprehensive Process Control

– Component Validation: Critical components (power capacitors, main ICs) undergo rigorous lifecycle testing and batch certification

– In-Process Monitoring: AOI systems verify solder quality and component alignment, complemented by ICT for electrical validation

– End-of-Line Verification: Extended burn-in testing simulates long-term operational conditions to identify early-life failures

3. Service-Oriented Design

– Clear interface labeling and silkscreen markings enable rapid fault identification during servicing

– Strategic test point access and modular architecture streamline maintenance and future upgrades

Conclusion

The All-in-One LCD TV Mainboard represents the pinnacle of integration technology in modern appliance manufacturing. Through precision SMT processes, hybrid assembly techniques, and uncompromising quality systems, LTPCBA delivers high-performance, reliable mainboard solutions that enhance product competitiveness and build market confidence for appliance manufacturers.

We invite television manufacturers and hardware solution providers to collaborate with us in advancing the next generation of smart home appliances through innovative engineering and manufacturing excellence.

LTPCBA — Twenty years of specialized expertise in appliance electronics manufacturing, delivering comprehensive solutions from PCB design through volume production.

Do you have any questions, or would you like to speak directly with a representative?