- Water Resistant: Membrane Switch is not only easy to clean, but most of the Membrane Switch's structure has reached IP65 or above. The main reason for the level of IP is the Membrane Switch design and material selection.

- Customization: Membrane Switch can be 100% customized to meet the different needs of users.

- Small size: Membrane Switch is a thin switch, most of the volume will not exceed 1.5mm. Save a lot of your space.

- Durability: Membrane Switch is very durable, even in a harsh environment, choosing a suitable design, long-term use can ensure that the function will not change.

Common additional designs of Automated Optical inspection AOI

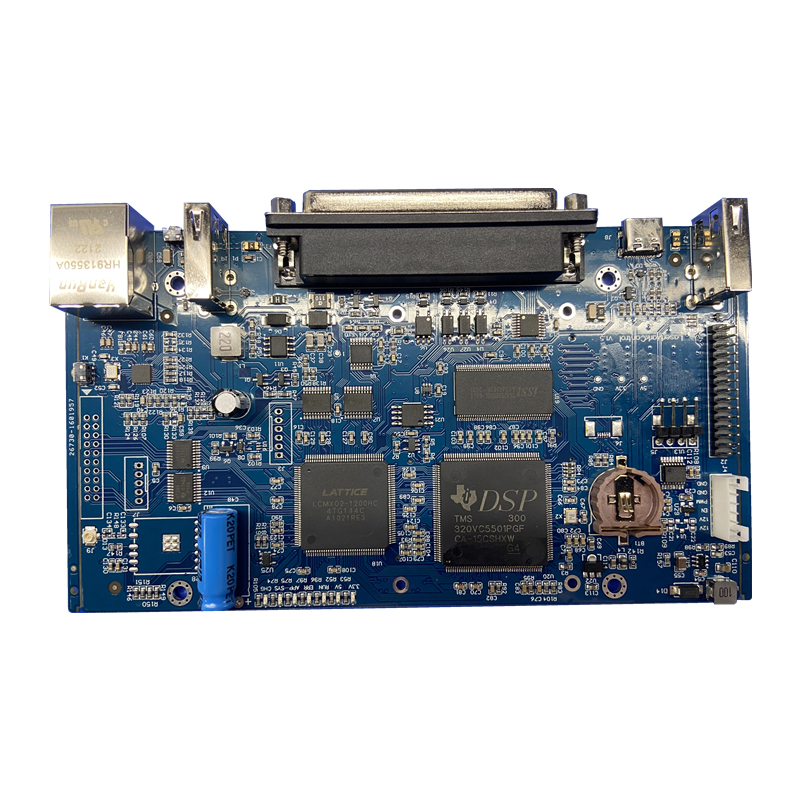

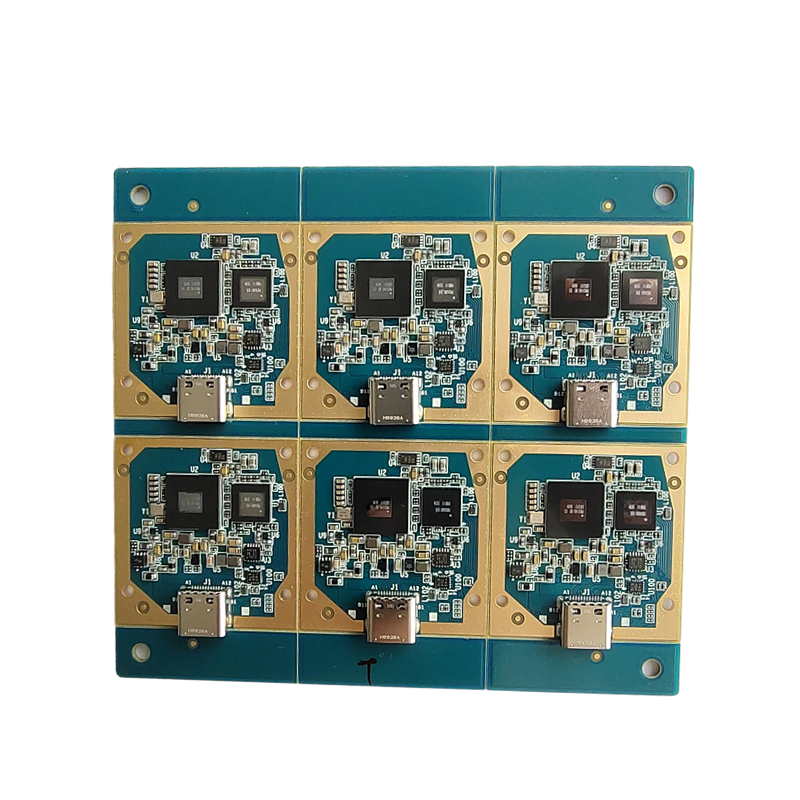

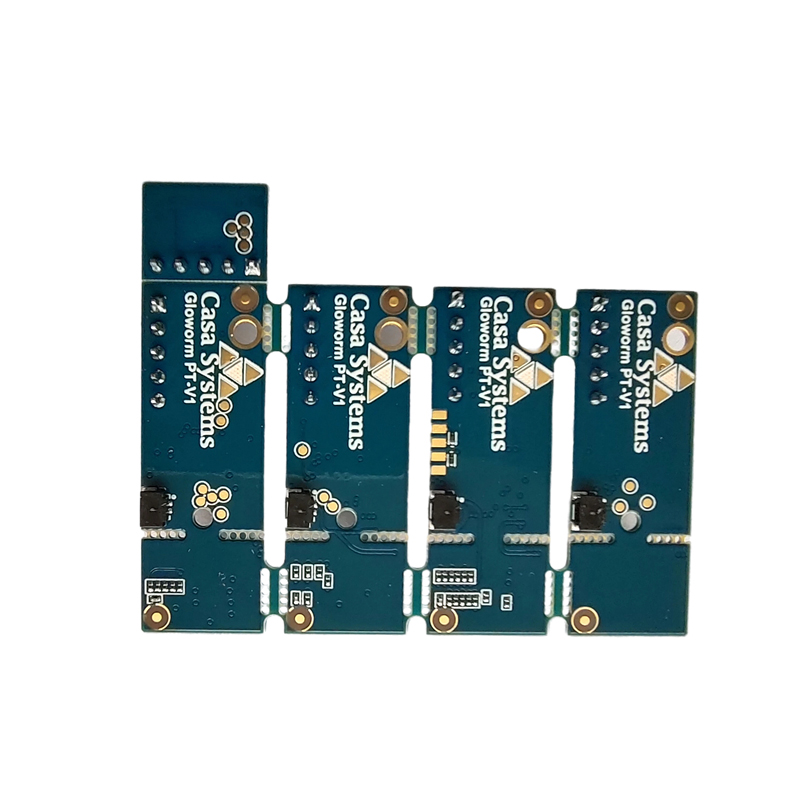

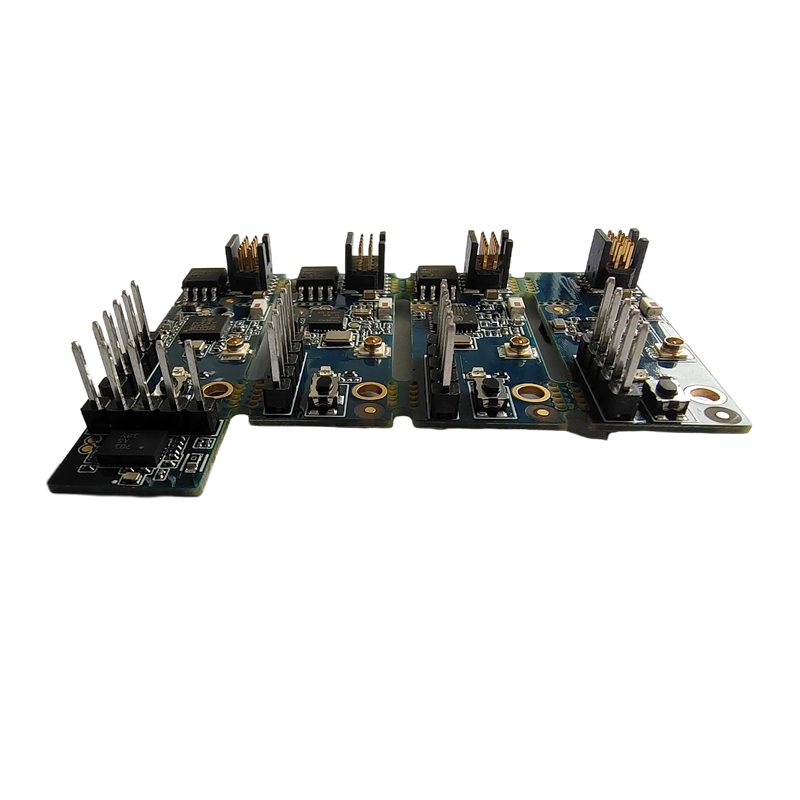

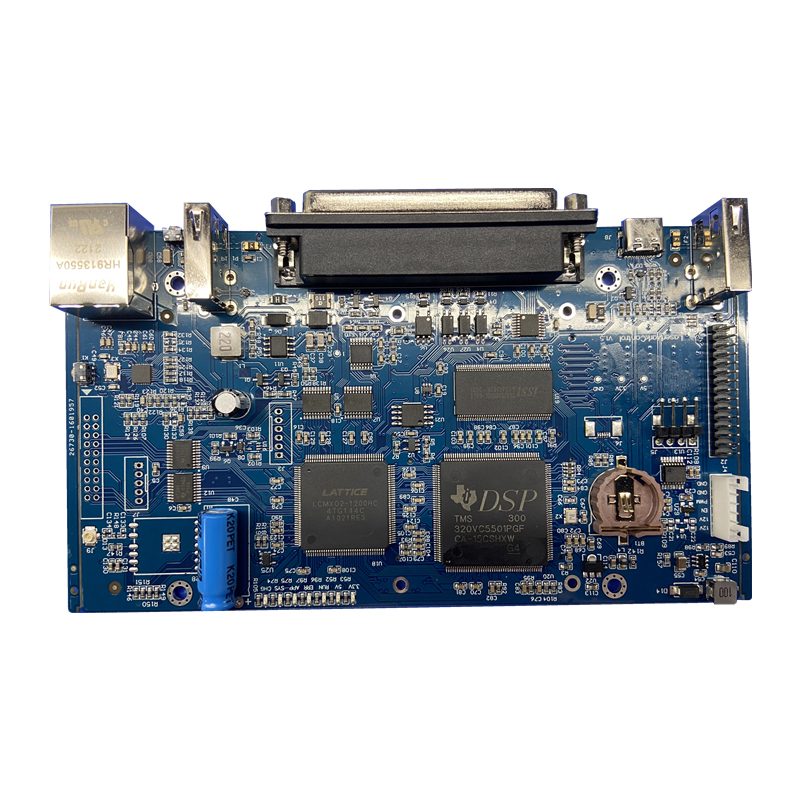

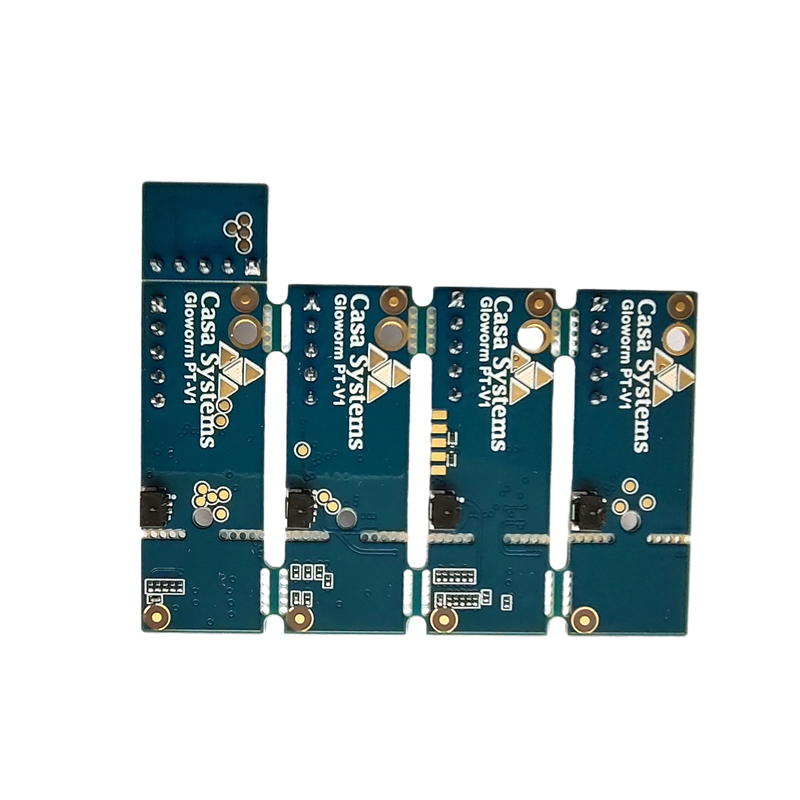

- Quality products from LT PCBA

EMI/RFI/ESD shielding

Backlight Solution

Tactile or Non-tactile

Back Panel

Digital Printing

Resin Dome