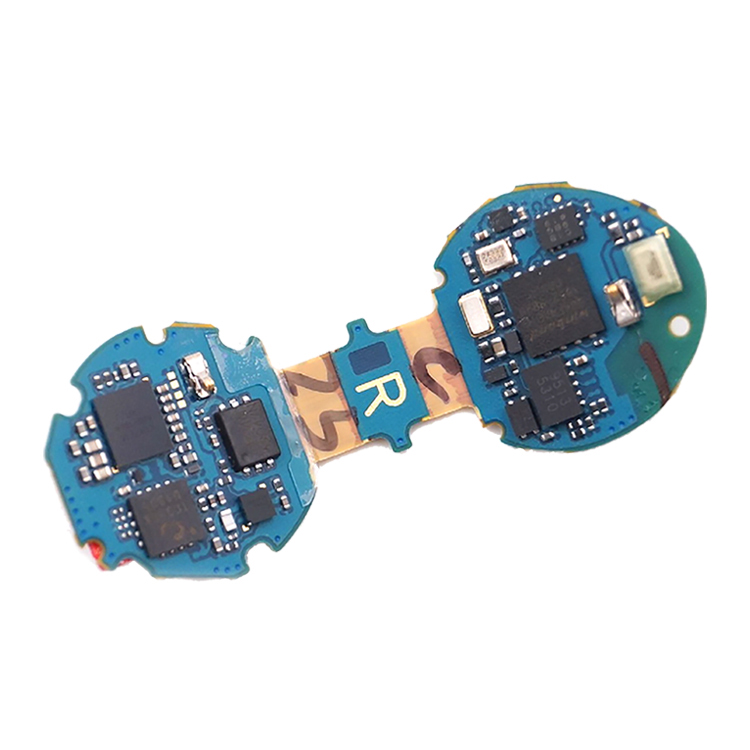

- PCB is one of the necessities of electronic products. According to statistics, in the global PCB application field,

The PCB market in the computer field is the largest, accounting for about 31%; followed by the communication field, accounting for about 28%;

Others are IC substrate, consumer electronics, industrial control and medical, automotive electronics and military aerospace and other fields.

Send Files To Us

Quote In 24 Hours

Confirm The File and Order

How to make your PCB Assembly Capabilityh work in the dark?

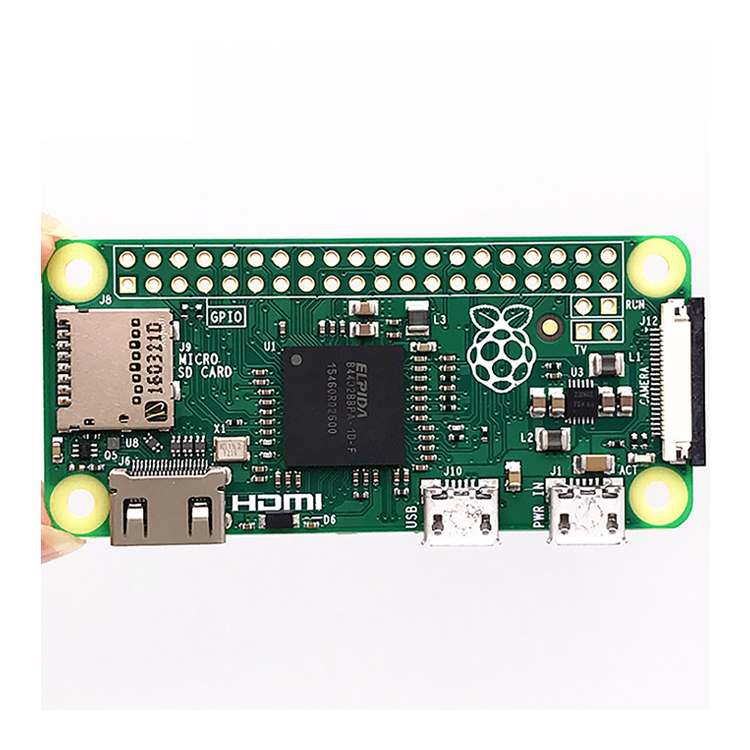

The maximum size of boards for SMD mounting in our production is 610 x 1220 mm

Production of electronic modules and blocks of special equipment class (class 3 according to the IPC-A-610D standard) of any complexity.

Repair of microcircuits using optical positioning for dismantling various types of SMD components (BGA, CSP, QFP, SOJ, etc.), as well as large components and microcircuits with a small lead pitch

Production of completely finished products, including special-purpose products with particularly stringent quality requirements, using automatic assembly and manual soldering.

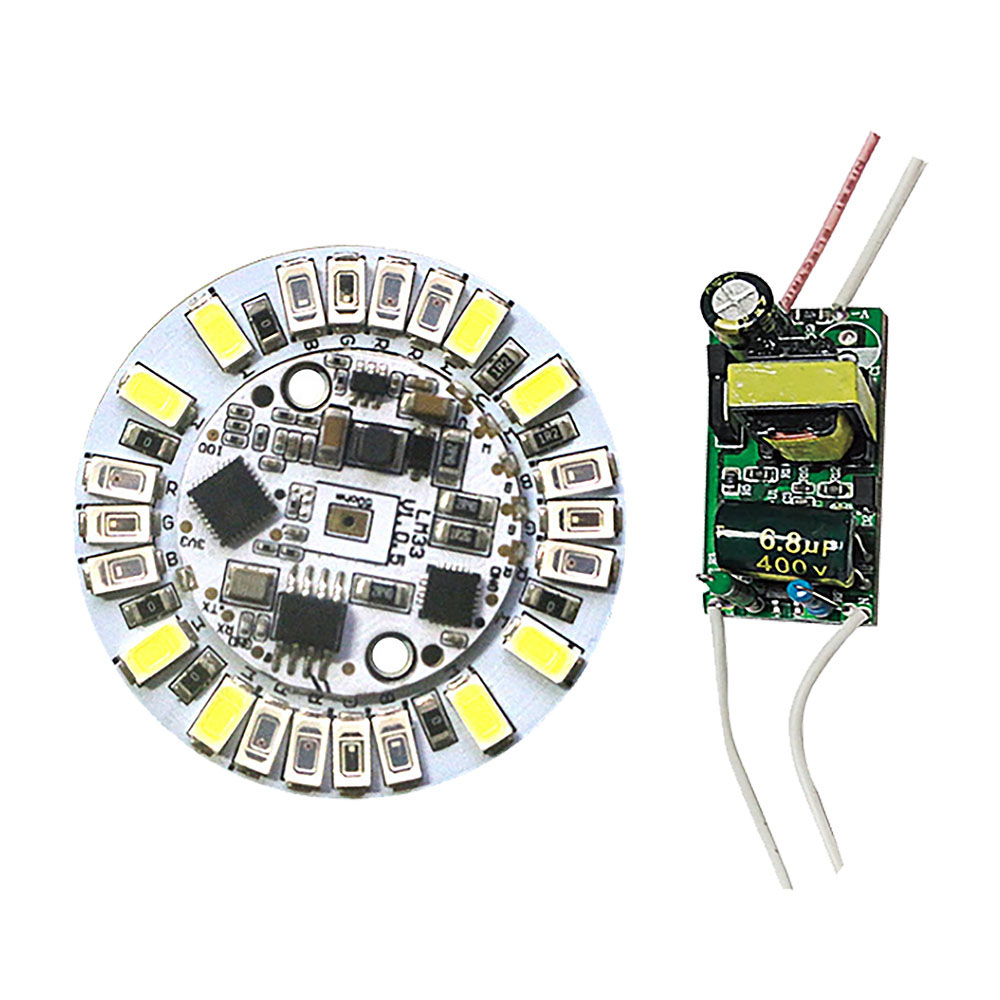

"Take you through four different Backligting Soulution"

Read More

PCB Assembly Capability advantage one

- Factory scale: The factory building covers an area of 50,000 square meters and has more than 500 employees, of which the ratio of professional and technical personnel is 68%.

The company is positioned to manufacture and process double-sided, four-layer and six-layer boards in large quantities. - High-quality raw materials: Sheet: Shengyi, Kingboard, Guoji, KB, Rogers, Taconic, Isola, Arlon, Nelco, Hitachi. Ink: Taiyo (Japan) Dry Film: Asahi (Japan), Dupont (US);

Potion : Rohm&Haas (US) Atotech (Germany) Umicore (Germany). - Leading equipment: invested heavily in a full set of high-end printed circuit board production equipment, including 70 drilling machines, 50 gong machines, 12 CCD automatic exposure machines, 5 VCP horizontal electroplating lines, 3 automatic sinking copper lines, and circuit LDI 8 exposure machines, 4 automatic screen printing lines, 3 OSP production lines, 2 vacuum DES etching lines, 2 automatic lamination lines, etc.

Read More

Read More

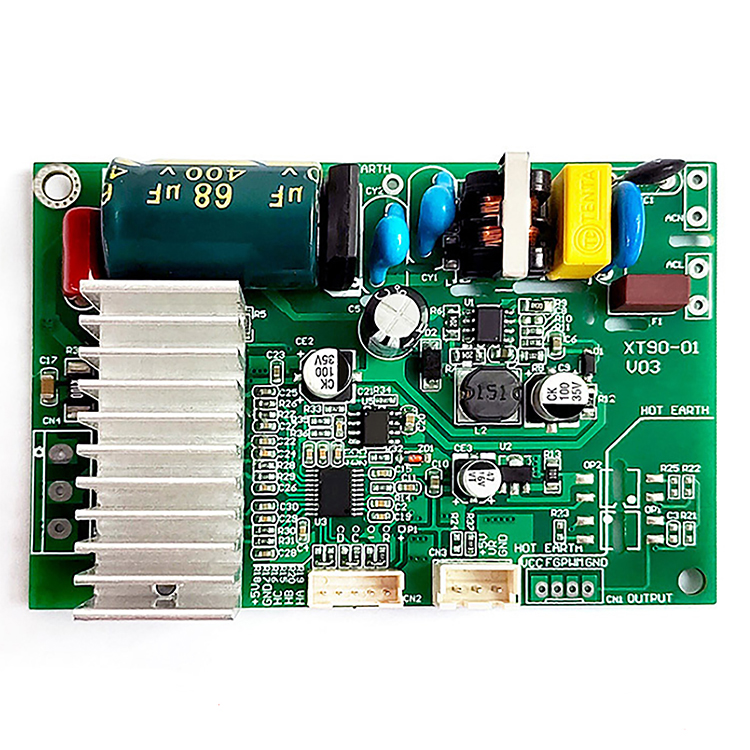

PCBA manufacturing advantage two

- Complete craftsmanship: There are few companies in the industry that are equipped with a full set of surface treatment equipment, which can fully respond to immersion gold, immersion silver, immersion tin, OSP, tin spraying, gold plating, thick gold plating, tin plating, silver plating and other related needs.

- Excellent quality: 36 processes in the whole process are tested layer by layer to ensure that the PCB products produced have passed the US UL, ISO9001, TS16949, CQC and other product safety certifications.

- Process capability: Jinhong Electronics' leading process capability: the maximum number of layers is 12L, the maximum board thickness is 3.0mm, the maximum aspect ratio is 8:1, the maximum copper thickness is 3oz, the maximum working board size is 520mm x 650mm, the thinnest four-layer board is 0.4mm, the minimum hole/pad 0.1/0.20mm minimum line width/line spacing 0.075/0.075mm

Read More

Read More

PCBA manufacturing advantage three

- Stable delivery: The entire ERP order management production system, real-time monitoring of various production links, clear control of the entire line, and special instrument testing of the PCB board throughout the entire process, and multiple production lines to effectively ensure on-time and punctual delivery.

- Reasonable price: An independent factory building completely belonging to the company has been established on the self-purchased land, with an independent environmental protection processing system. All processes from material cutting to testing are completed in the factory, eliminating the need for intermediate outsourcing links and maximizing the reduction of customers. cost

- Intimate service: quick quotation within 30 minutes, quick response to customer needs within 1 hour, online customer service 24 hours a day, handling emergency situations and carrying out proactive customer return visits and services in a timely manner, allowing you to enjoy more intimate after-sales service

Read More

Read More

What are the factors that affect the price of PCB

- Raw materials: The raw materials used for PCB proofing include "ink" and "plate". Different brands/grades of raw materials are selected, and the price also changes. High-quality raw materials are not only baked at high temperature, but also have strong flame retardancy and bright colors. Bright and long lasting.

- Process requirements: Common surface treatment requirements for PCB proofing include: thick plate, number of layers, copper thickness, minimum aperture/line width/line moment, surface treatment, etc. The higher the parameters, the more expensive the price, followed by the surface treatment. Tin is expensive, and the smaller the process capability parameter, the more expensive the price.

- Production Quantity: The more PCB proofing production quantity, the more affordable the price. Our company focuses on mass production. The cost of PCB proofing in the early stage can be returned according to the situation during mass production. Serve.

- Production cycle: 4-5 days for conventional PCB single and double-sided board proofing, 6-8 days for PCB multi-layer board proofing, and expedited order processing according to customer requirements. The shorter the delivery time, the more expensive the price, and the old customers monthly There are two free rush orders.

Read More

Read More

Our advantage

- Advantages: 40 technological processes, 113 precision processes

- Strict selection of materials: all brand materials are used, and the raw materials are returned immediately if they fail to pass the test of various indicators

- Precision machining: LDI laser exposure machine, vacuum etching machine, character inkjet printer and other imported equipment greatly improve the machining accuracy

- Full product inspection: Each production link has QC special inspection, operator self-inspection, QA sampling inspection product layer by layer

- Functional guarantee: Imported instruments and equipment such as quadratic element, copper thickness tester, impedance tester and gold thickness tester guarantee performance

Read More

Advantages od Cooperation

Reasons To Persuade You

Contact