News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

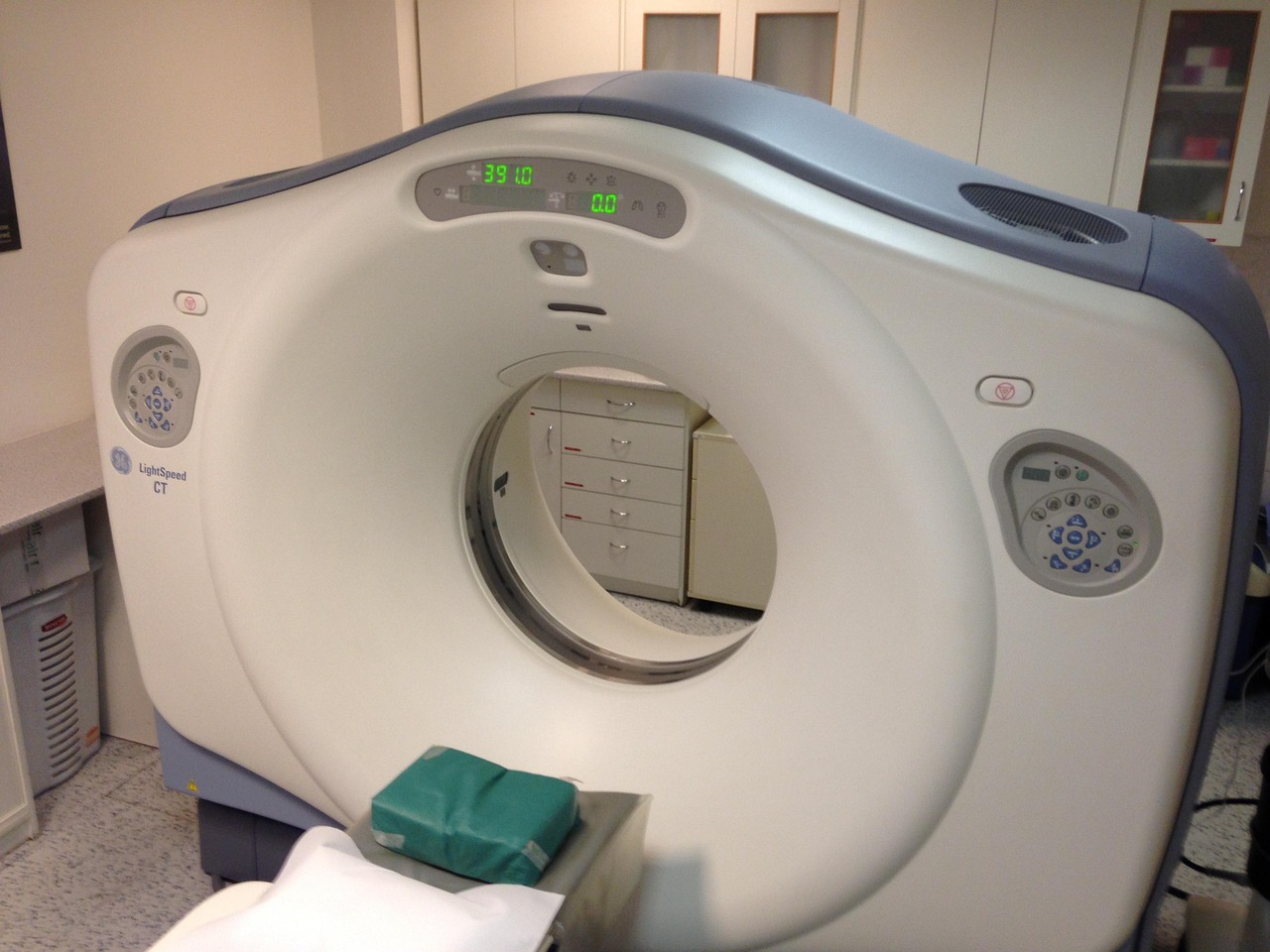

Accelerating Medical Device Innovation: The Role of Quick-Turn PCB Prototyping

11 Sep, 2025

In the fast-evolving landscape of medical technology, speed and precision are inseparable from patient safety and market success. Medical device developers face immense pressure to iterate on designs, validate new functionalities, and meet strict regulatory deadlines—all while ensuring every component adheres to the highest standards of reliability. This is where quick-turn PCB prototyping emerges as… Continue reading Accelerating Medical Device Innovation: The Role of Quick-Turn PCB Prototyping

Learn More -

Sustainability in Medical Device PCB Prototyping: Why It Matters and How to Implement It

11 Sep, 2025

The medical device industry is undergoing a critical shift toward sustainability—one that extends beyond patient care to encompass environmental responsibility. As global awareness of electronic waste (e-waste) and toxic material pollution grows, and regulatory frameworks tighten, medical device manufacturers are rethinking how they design, prototype, and produce printed circuit boards (PCBs). For prototype PCBA medical… Continue reading Sustainability in Medical Device PCB Prototyping: Why It Matters and How to Implement It

Learn More -

2025 Guide to PCBA Waterproofing: Proven Methods, Materials, and Quality Assurance

10 Sep, 2025

Water damage remains one of the top causes of PCBA (Printed Circuit Board Assembly) failure, costing industries billions annually in rework, downtime, and product recalls. As electronic devices increasingly operate in harsh environments—from outdoor IoT sensors and marine equipment to industrial machinery and wearable tech—demand for robust waterproofing solutions has never been higher. In 2025,… Continue reading 2025 Guide to PCBA Waterproofing: Proven Methods, Materials, and Quality Assurance

Learn More -

Ensuring Quality and Safety in Medical-Grade PCBA Prototypes: Standards, Design, and Testing

10 Sep, 2025

In the medical device industry, where a single component failure can compromise patient safety or disrupt critical healthcare workflows, medical-grade PCBA prototypes demand uncompromising quality and rigorous safety protocols. Unlike consumer electronics, these prototypes must operate reliably in harsh clinical environments—from the sterility of operating rooms to the constant movement of wearable monitors—while adhering to… Continue reading Ensuring Quality and Safety in Medical-Grade PCBA Prototypes: Standards, Design, and Testing

Learn More -

Conformal Coating, Potting, or Nano Coating: Choosing the Right Waterproof Solution for Your PCBA

09 Sep, 2025

Moisture, dust, and corrosive chemicals are silent killers of printed circuit board assemblies (PCBAs). Even small amounts of water can cause short circuits, corrosion of copper traces, or component failure—costing businesses thousands in rework, downtime, and product recalls. For PCBAs used in harsh environments (e.g., marine equipment, industrial machinery, or outdoor electronics), selecting the right… Continue reading Conformal Coating, Potting, or Nano Coating: Choosing the Right Waterproof Solution for Your PCBA

Learn More -

Step-by-Step Guide to Instant Online Turnkey PCBA Quoting: Get Accurate Pricing in Minutes

09 Sep, 2025

In the fast-paced world of electronics manufacturing, waiting weeks for a PCBA quote can derail your project timeline. Traditional quoting processes—filled with back-and-forth emails, manual file reviews, and disjointed vendor communication—often cause delays that push product launches further out. Fortunately, modern online tools have transformed this experience, letting you secure accurate turnkey PCBA quotes instantly,… Continue reading Step-by-Step Guide to Instant Online Turnkey PCBA Quoting: Get Accurate Pricing in Minutes

Learn More