News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

The Requirements for Printed Circuit Boards in Automotive Electronic Systems (2) Vehicle Control Systems

15 Oct, 2025

Meta Description: Learn the PCB requirements for EV vehicle control systems, including VCU, ECU, TCU, ABS/ESC, and steering modules. Explore safety-critical PCB design, ISO 26262 compliance, multilayer boards, and EMI/EMC design strategies. Introduction Vehicle control systems serve as the “brain and nerves” of electric vehicles (EVs), orchestrating the coordination of driving functions and safety mechanisms.… Continue reading The Requirements for Printed Circuit Boards in Automotive Electronic Systems (2) Vehicle Control Systems

Learn More -

The Requirements for Printed Circuit Boards in Automotive Electronic Systems (1) Power & Energy Systems

15 Oct, 2025

Meta Description: Discover the key PCB design and manufacturing requirements for EV power and energy systems, including battery packs, BMS, on-board chargers, DC-DC converters, and traction inverters. Learn about high-voltage PCB design, thermal management, thick copper boards, and insulation standards. Introduction Power and energy systems serve as the core of electric vehicles (EVs), enabling the… Continue reading The Requirements for Printed Circuit Boards in Automotive Electronic Systems (1) Power & Energy Systems

Learn More -

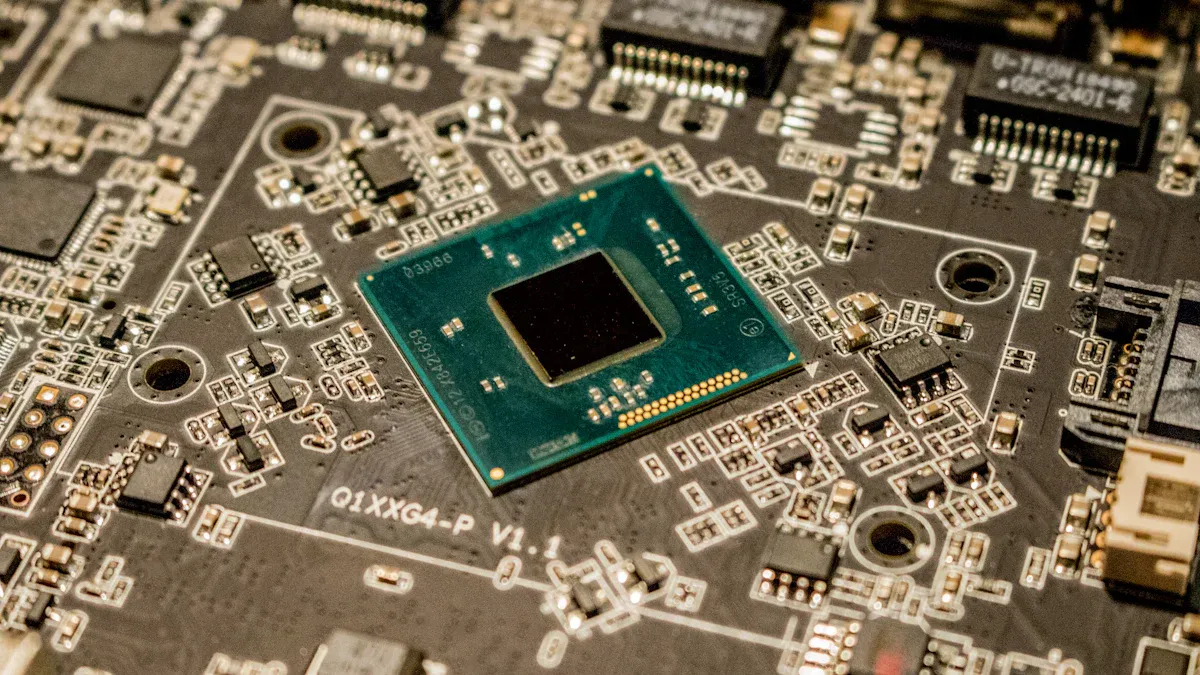

Top 10 PCB Packaging Types Used in Modern Electronic Devices(Part 2)

14 Oct, 2025

QFN (Quad Flat No-lead) Overview You see QFN in many new electronics today. This package is flat and square. It does not have leads sticking out. Metal pads are under the chip. QFN sits close to the PCB. This helps make devices smaller and lighter. The pad on the bottom helps move heat away. This… Continue reading Top 10 PCB Packaging Types Used in Modern Electronic Devices(Part 2)

Learn More -

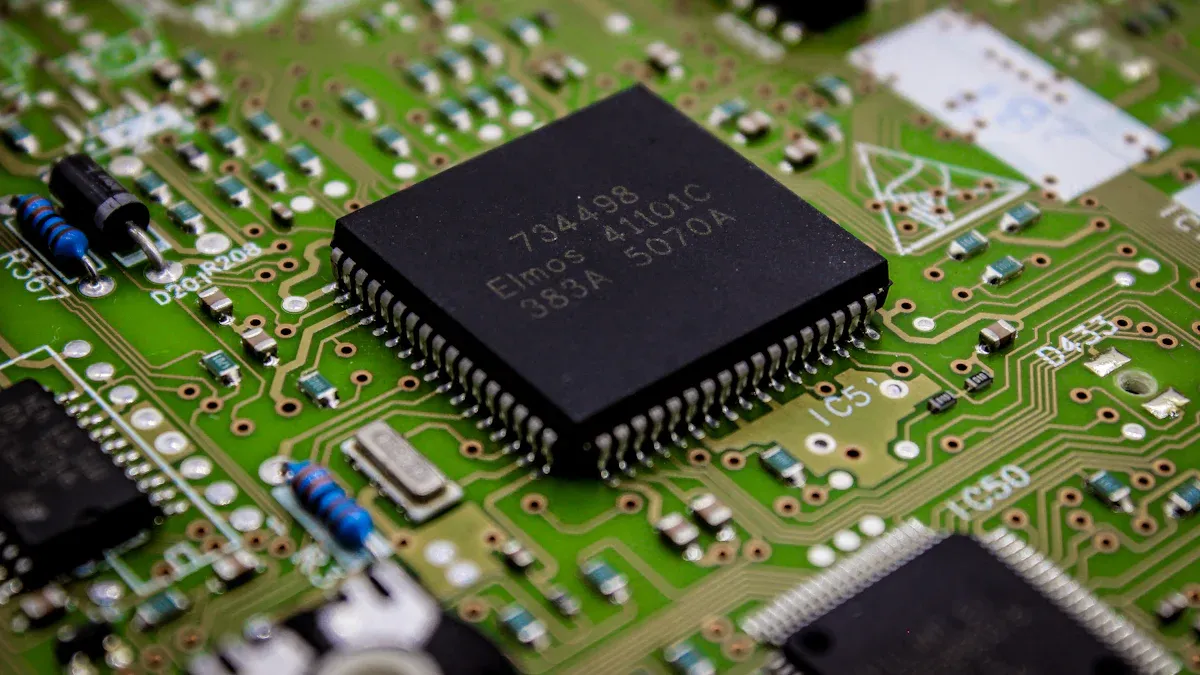

Top 10 PCB Packaging Types Used in Modern Electronic Devices(Part 1)

14 Oct, 2025

You can find the top ten mainstream electronic device packaging types of PCB used in today’s electronics. These packaging types include Surface Mount, Through-Hole, Hybrid Packaging, and more. The packaging you choose can affect the overall size of the device, improve its performance, and speed up the manufacturing process. For instance, surface mount technology enables the creation… Continue reading Top 10 PCB Packaging Types Used in Modern Electronic Devices(Part 1)

Learn More -

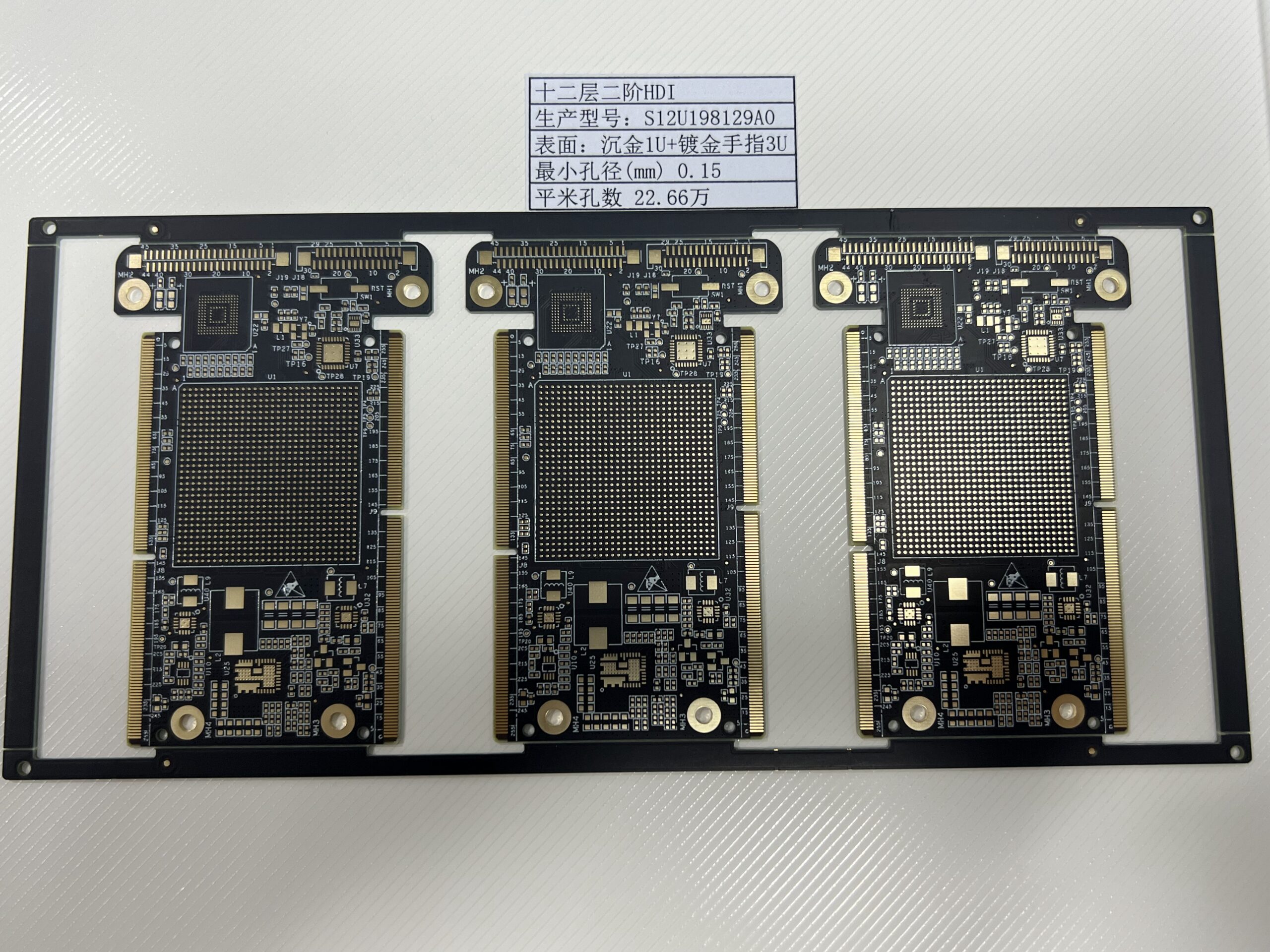

Optimizing HDI PCB Assembly: Key Steps & LTPCBA’s Expert Solutions for High-Density Designs

14 Oct, 2025

In today’s era of miniaturized, high-performance electronics—from 5G routers and wearable health monitors to aerospace sensors and medical imaging devices—High-Density Interconnect (HDI) PCBs have become indispensable. Their ability to pack more components and connections into smaller spaces, while delivering faster signal speeds and better reliability, makes them a cornerstone of modern design. However, optimizing HDI… Continue reading Optimizing HDI PCB Assembly: Key Steps & LTPCBA’s Expert Solutions for High-Density Designs

Learn More -

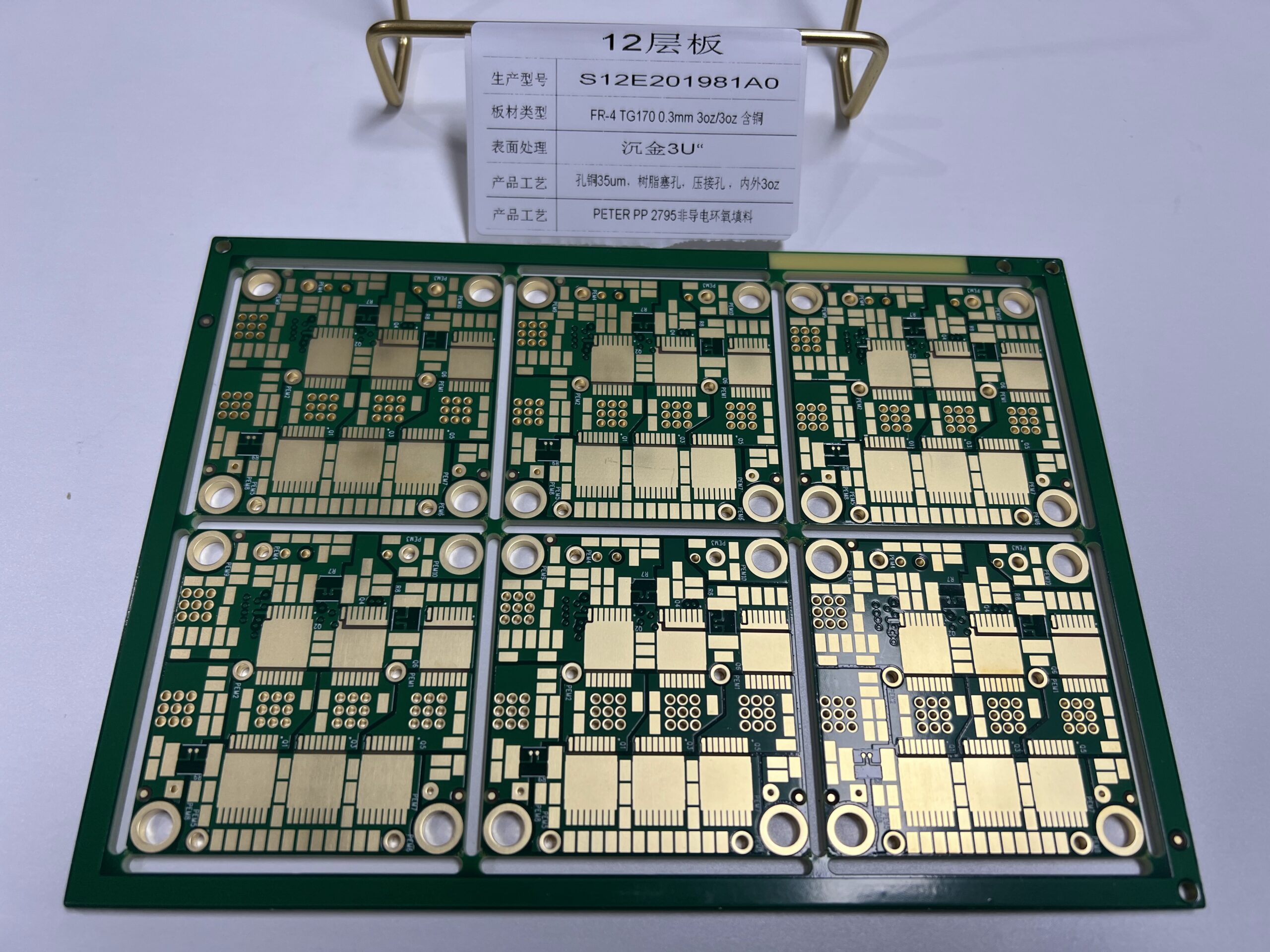

Heavy Copper vs Standard PCB Assembly: LTPCBA’s Optimal Solutions

13 Oct, 2025

When selecting a PCB assembly for your project,whether it’s a everyday consumer device or a high-power industrial system—the choice between heavy copper and standard PCBs defines performance, reliability, and cost-effectiveness. At LTPCBA, we’ve spent decades mastering both technologies, helping clients navigate tradeoffs between current capacity, thermal management, and manufacturing feasibility. This guide breaks down the… Continue reading Heavy Copper vs Standard PCB Assembly: LTPCBA’s Optimal Solutions

Learn More