News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

Top Benefits of Mixed PCB Assembly Combining SMT and THT Technologies

02 Dec, 2025

Mixed Assembly PCB combines SMT and THT technologies. SMT offers speed and precision, while THT enhances the strength and durability of the boards. This mixed assembly approach is particularly effective in compact environments, accelerating production and enabling versatile designs. Engineers are currently utilizing this method for applications in automotive and medical devices. Key Takeaways # Mixed PCB assembly… Continue reading Top Benefits of Mixed PCB Assembly Combining SMT and THT Technologies

Learn More -

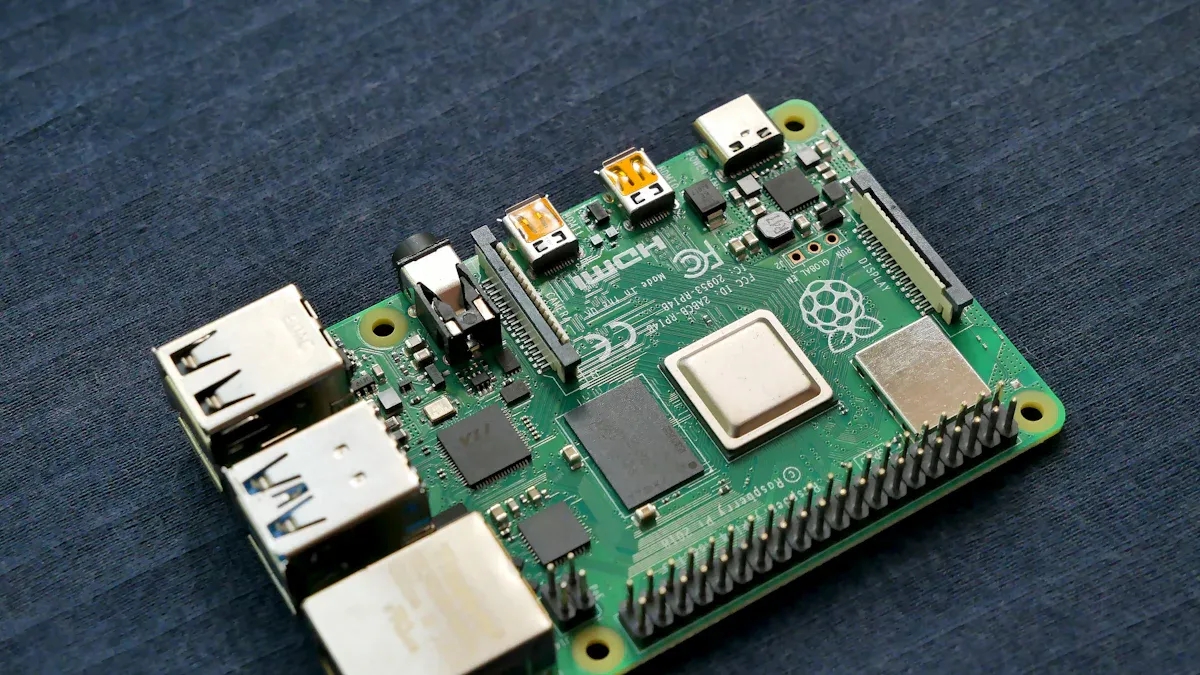

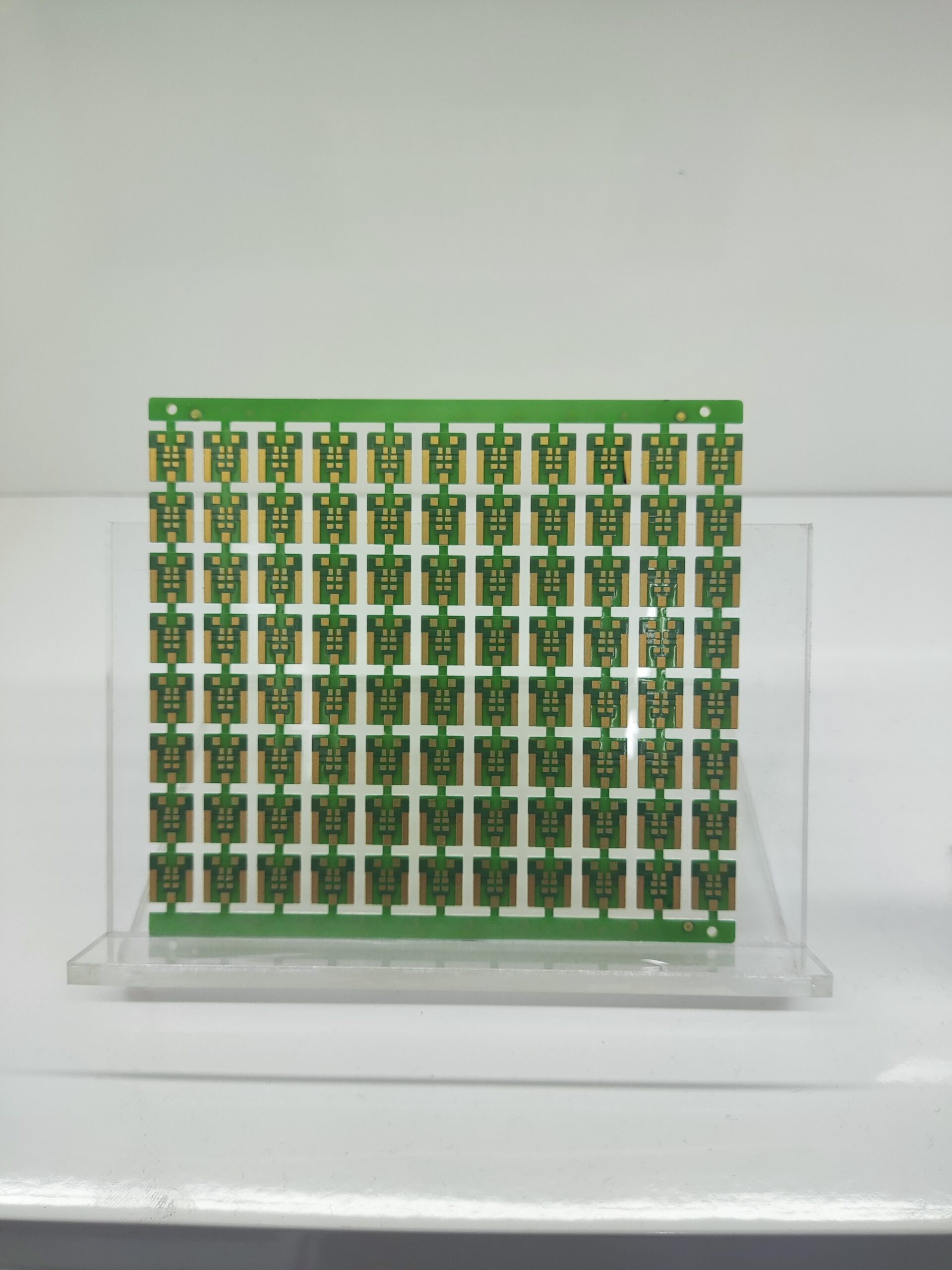

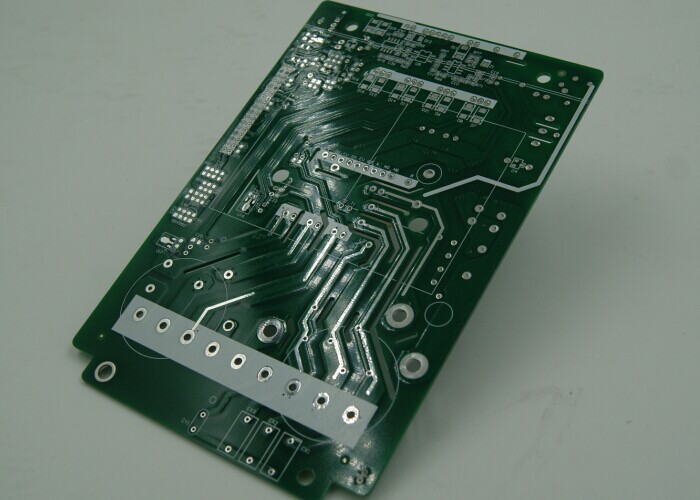

LTPCBA EMC Protection Board

02 Dec, 2025

As a professional PCBA manufacturer, LTPCBA introduces this EMC protection bare PCB board, featuring modular design and high compatibility to serve as a core platform for electromagnetic compatibility (EMC) protection in electronic devices. 1. Technical Features: Precision Engineering for EMC Protection – Panelized Design & Standardization Utilizes multi-unit panel layout with regular array arrangement, compatible… Continue reading LTPCBA EMC Protection Board

Learn More -

Common problems and solutions in PCB design for SMT processing technology requirements

28 Nov, 2025

You face special problems when it comes to PCB design for SMT. Fixing these problems helps make production easier and products better. Surface mount technology requires careful PCB design and good materials. Ignoring these needs can lead to expensive mistakes. Utilizing smart solutions can save time and enhance product quality. Key Takeaways Signal Integrity in… Continue reading Common problems and solutions in PCB design for SMT processing technology requirements

Learn More -

What Are IC Substrate PCBs and Their Key Functions?

28 Nov, 2025

IC substrate PCBs are special circuit boards for modern electronics. They link tiny chips to bigger systems for smooth data transfer. Small and fast devices need IC substrates to work well. For example: These boards are very important in areas like space, military, and communication, where they must be dependable. Key Takeaways Key Functions of… Continue reading What Are IC Substrate PCBs and Their Key Functions?

Learn More -

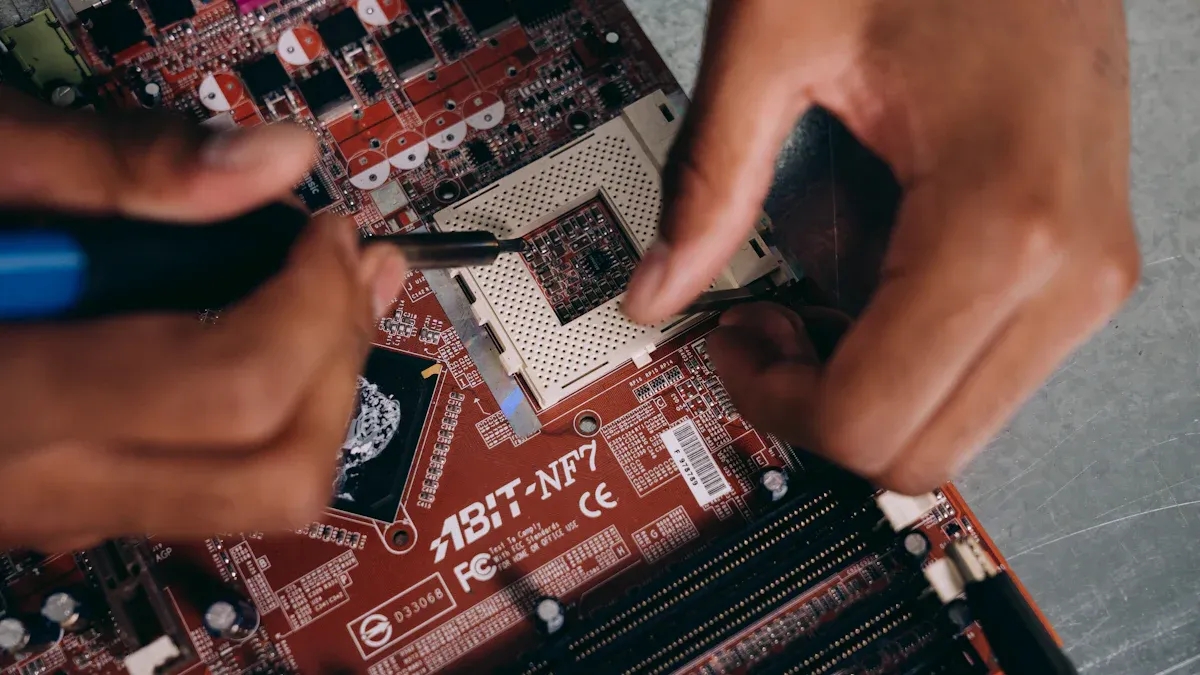

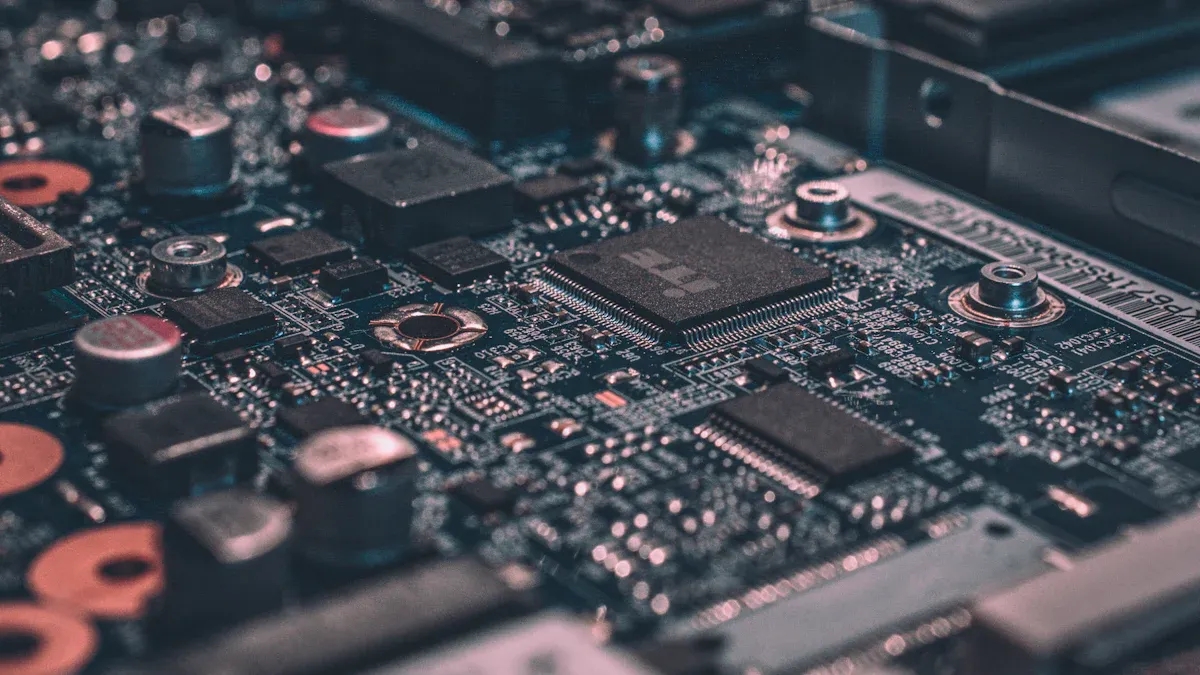

Integrated Design of Smart Device Motherboards

27 Nov, 2025

As specialists in SMT manufacturing at LTPCBA, we regularly engage with design and production requirements for industrial-grade smart device motherboards. Today, we analyze a typical POS/handheld terminal motherboard to share our professional insights and technical capabilities in precision circuit board manufacturing. Multi-Functional Integration: Core Value of Smart Device Motherboards This motherboard exemplifies the high integration… Continue reading Integrated Design of Smart Device Motherboards

Learn More -

How to make the electroplating filling holes of HDI PCB laser drilling more flat

27 Nov, 2025

Flat electroplating filling holes are important for HDI PCBs. They help the boards work well and last longer. Reverse pulse plating (RPP) stops paste from blocking holes. This lowers production steps and saves money. Methods like mSAP use very thin copper foil. This makes the surface even and smooth, which is needed for modern designs like via-in-pad and stacked… Continue reading How to make the electroplating filling holes of HDI PCB laser drilling more flat

Learn More