News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

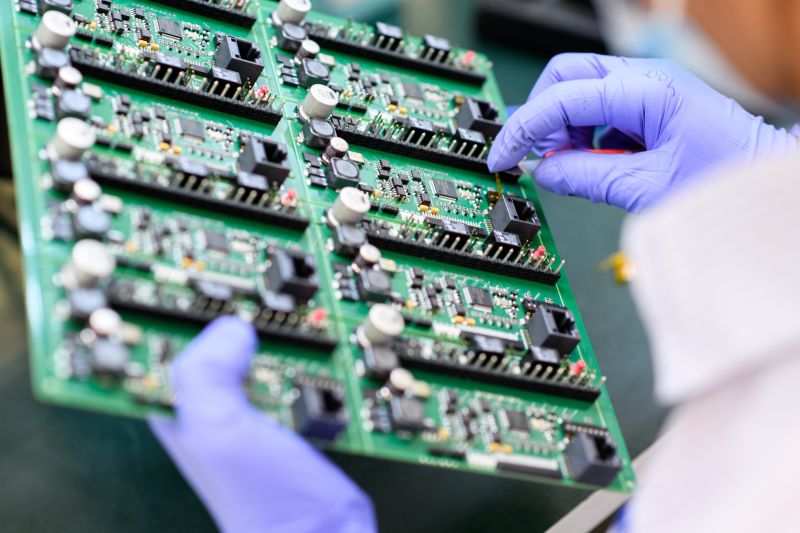

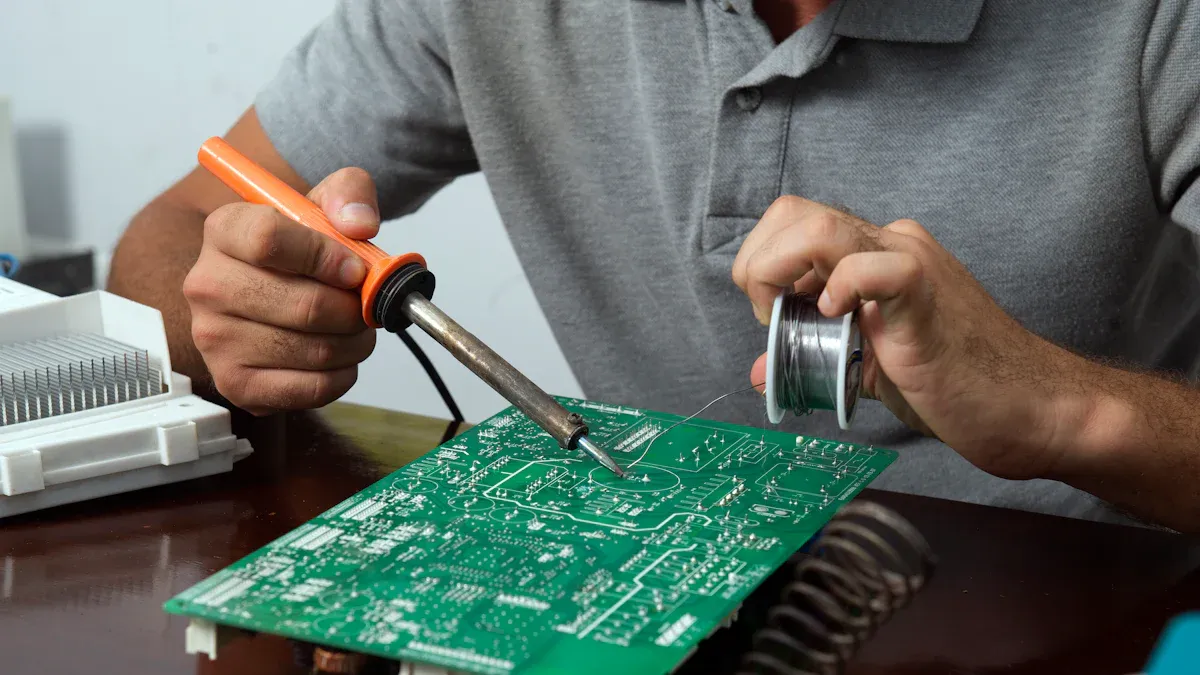

Through-Hole DIP PCBA: Manufacturing Process, Quality Control, and Industry Applications

02 Jul, 2025

Key Takeaways Manufacturing Process of Through-Hole Assembly at LTPCBA Precision Drilling for Through-Hole Components Drilling is the foundational step in through-hole assembly. LTPCBA utilizes advanced tools to ensure every hole meets exacting standards: These drilling steps fortify designs to withstand harsh conditions. Component Insertion Techniques Accuracy is paramount in through-hole component placement. LTPCBA employs both… Continue reading Through-Hole DIP PCBA: Manufacturing Process, Quality Control, and Industry Applications

Learn More -

24-Pin DIP Cable Assemblies: Comprehensive Guide to Applications, Specifications, and Manufacturing

01 Jul, 2025

Key Takeaways Industry Applications of 24-Pin DIP Cables Consumer Electronics Innovation Industrial Automation Solutions Medical Device Reliability Automotive and EV Systems Aerospace and Defense Technical Specifications and Standards Electrical Performance Metrics Parameter Rating Application Impact Contact Resistance ≤10mΩ Minimizes power loss Insulation Resistance ≥5000MΩ Prevents electrical leakage Current Rating 3A per pin Supports moderate power… Continue reading 24-Pin DIP Cable Assemblies: Comprehensive Guide to Applications, Specifications, and Manufacturing

Learn More -

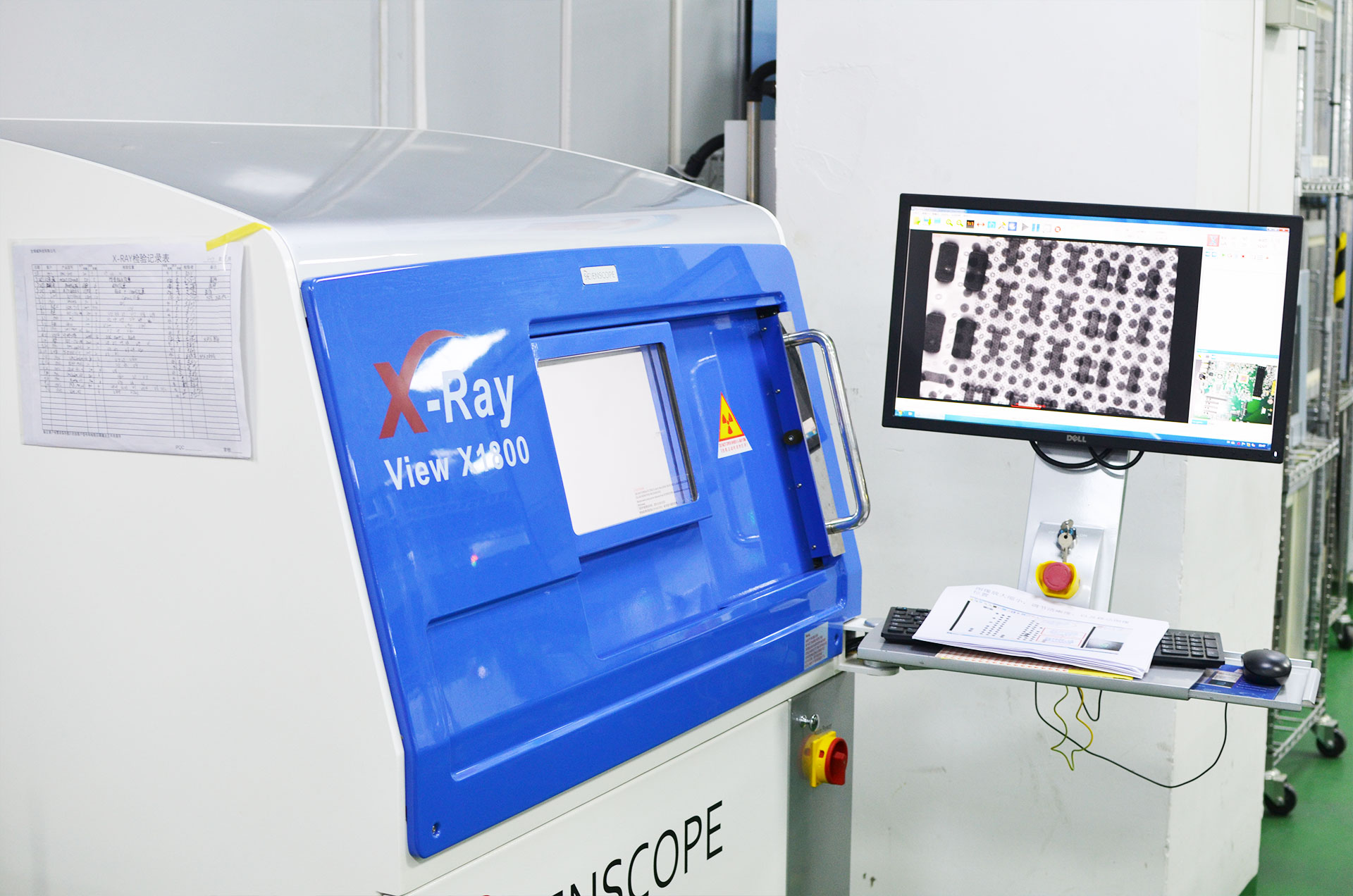

How X-Ray Inspection Enhances Quality Control in PCBA Manufacturing

01 Jul, 2025

Key Takeaways The Role of X-Ray Inspection in PCBA Manufacturing Understanding X-Ray Inspection Technology X-Ray Inspection revolutionizes PCBA quality control by using imaging to uncover hidden defects missed by other methods. This is critical for ensuring product safety and functionality in electronics, automotive, and aerospace sectors. The system captures clear images of internal PCB components,… Continue reading How X-Ray Inspection Enhances Quality Control in PCBA Manufacturing

Learn More -

Essential Guide to Conformal Coating in PCBA Production: Key Steps and Best Practices

01 Jul, 2025

Key Takeaways The Role and Advantages of Conformal Coating Core Protection Mechanisms Conformal coatings form a micro-thin barrier that: Performance Enhancement Metrics Benefit Impact Dielectric Strength >6000V/mil insulation Thermal Stability Withstands 1000+ thermal cycles Surface Insulation Resistance (SIR) >10¹² ohms post-coating Industry Applications Major Conformal Coating Types for PCBA Acrylic Coatings Silicone Coatings Parylene Coatings… Continue reading Essential Guide to Conformal Coating in PCBA Production: Key Steps and Best Practices

Learn More -

Conformal Coating Types: A Comprehensive Guide to Advantages, Disadvantages, and Selection

30 Jun, 2025

Key Takeaways Major Conformal Coating Categories Acrylic Coatings Application Flexibility: Spray/dip/brush application, ideal for rapid prototyping. Epoxy Coatings Chemical Fortress: Renowned for harsh environment durability. Silicone Coatings Humidity Mastery: Unique vapor permeability with liquid water blockage. Polyurethane Coatings Wear Resistance Champion: Proven in abrasion-intensive environments. Test Method Result Tabor Abrasion <5mg weight loss Puncture Resistance… Continue reading Conformal Coating Types: A Comprehensive Guide to Advantages, Disadvantages, and Selection

Learn More -

Conformal Coating Challenges in SMT Assembly: Technical Hurdles and Best Practices

30 Jun, 2025

Key Takeaways Common Conformal Coating Defects Inconsistent Thickness Issues Adhesion Failures Voids and Bubbles Chemical Compatibility Issues Coating Type Incompatible Surface Finishes Failure Mode Epoxy ENIG (gold over nickel) Black pad corrosion Silicone OSP Delayed curing Urethane HASL Brittle joints Root Causes of Coating Failures Surface Contamination Environmental Fluctuations Application Method Flaws Curing Process Errors… Continue reading Conformal Coating Challenges in SMT Assembly: Technical Hurdles and Best Practices

Learn More