News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

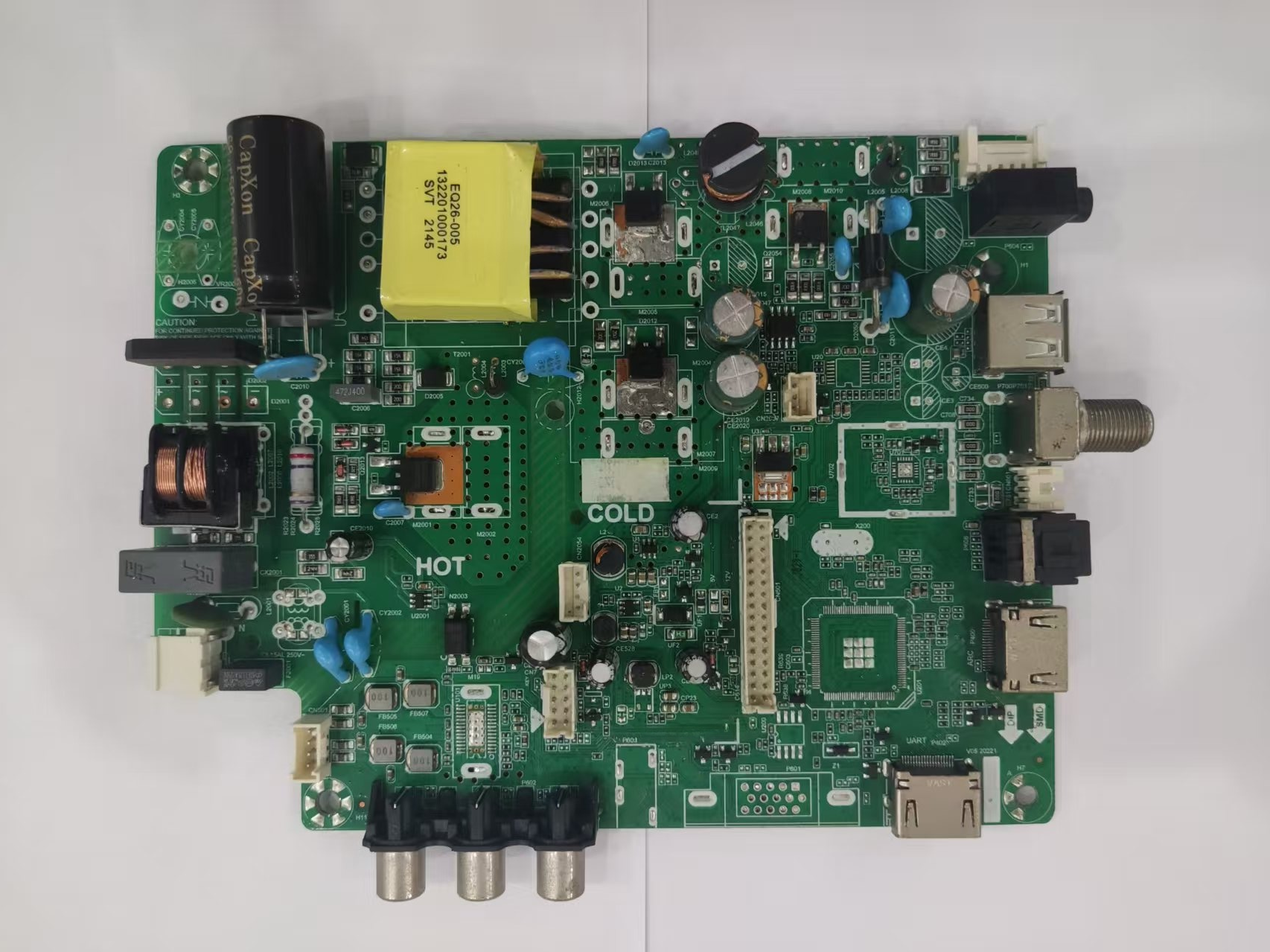

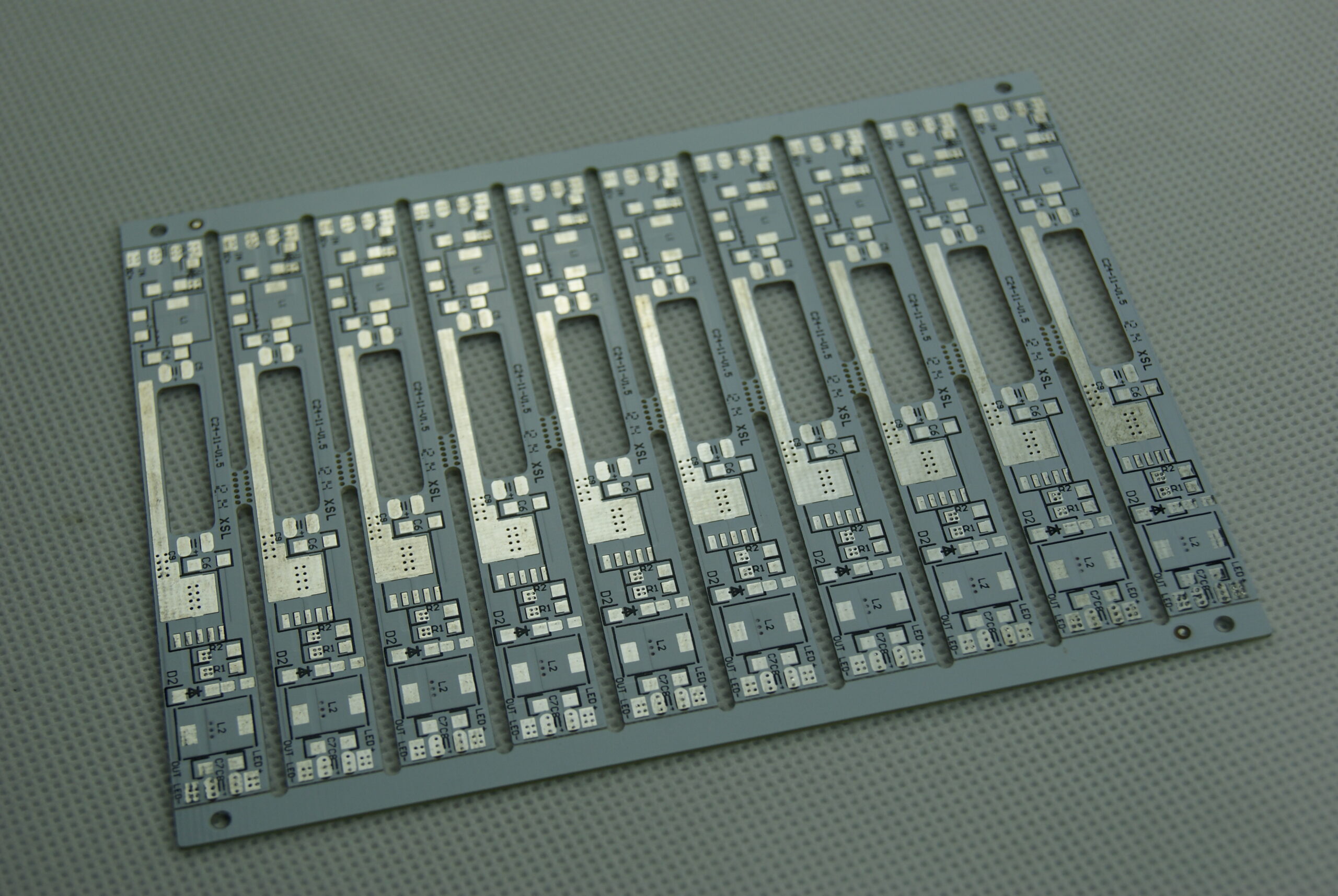

All-in-One LCD TV Mainboard

21 Nov, 2025

Amid the growing trends of smart and compact home appliances, the integration level and reliability of LCD TV mainboards have become pivotal to overall system performance. This analysis examines a typical All-in-One LCD TV Mainboard—integrating driver, power supply, and signal processing functions—to dissect its technical features and manufacturing processes, while showcasing LTPCBA’s expertise in home… Continue reading All-in-One LCD TV Mainboard

Learn More -

Why solder mask LDI can produce smaller solder mask bridges in the PCB production process

21 Nov, 2025

Solder mask LDI helps make smaller solder mask bridges easily. It keeps a solder mask gap of at least 3W from signal lines. The thickness is controlled within ±5μm for accuracy. This reduces solder mask mistakes by 18% in smartphone PCBs. LTPCBA uses this technology to make strong PCBs for modern needs. Key Takeaways Understanding solder mask bridges in… Continue reading Why solder mask LDI can produce smaller solder mask bridges in the PCB production process

Learn More -

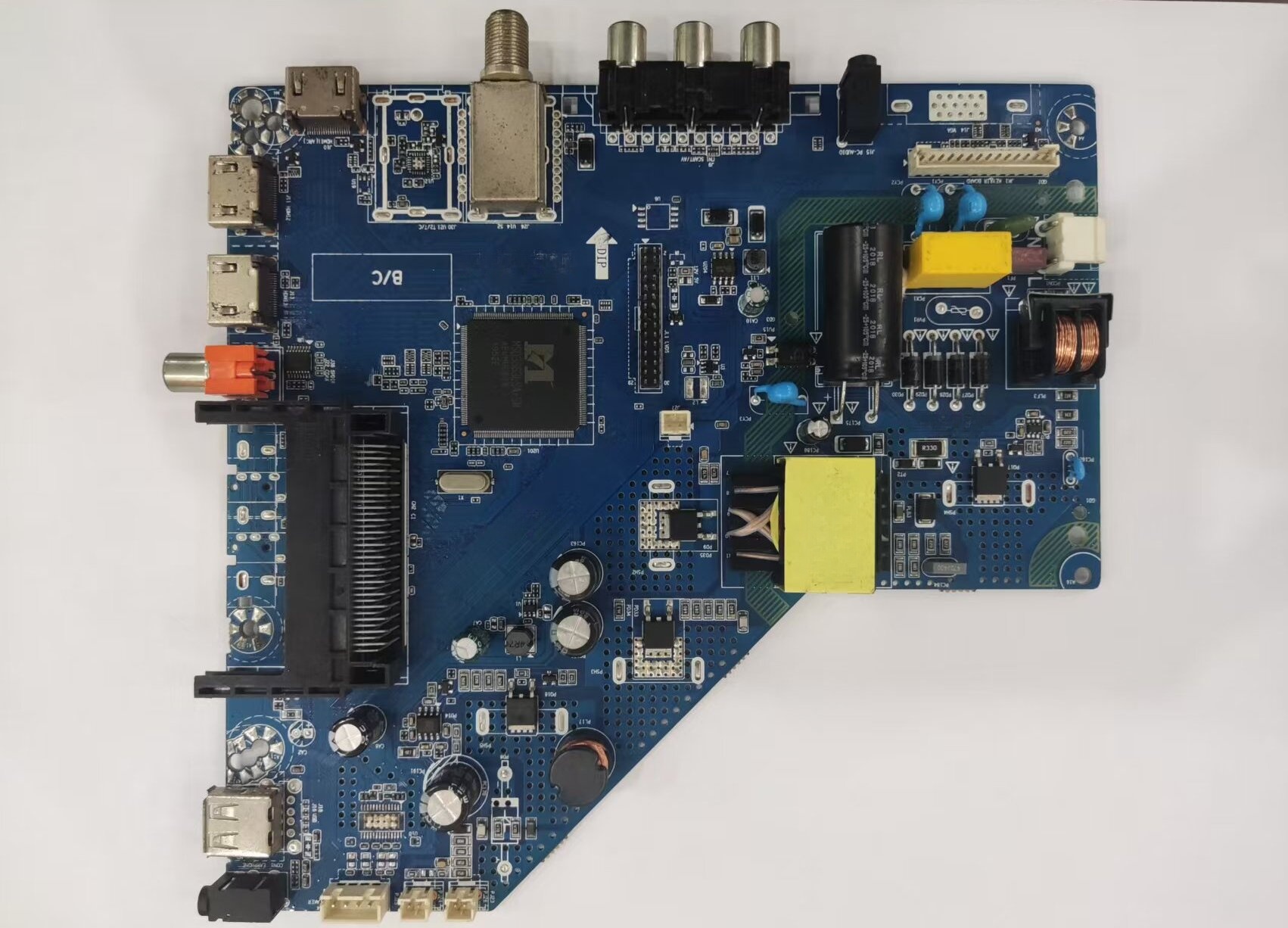

【LTPCBA Manufacturing】Powering Your Display Solutions with a Universal LCD TV Mainboard

20 Nov, 2025

As a specialist in end-to-end PCB fabrication and SMT assembly, LTPCBA is proud to present our high-performance Universal LCD TV Mainboard — engineered for reliability and global compliance. This mainboard serves as the core component for a wide range of display applications, from commercial installations to residential TV systems. Key Features & Specifications: ◾ Broad… Continue reading 【LTPCBA Manufacturing】Powering Your Display Solutions with a Universal LCD TV Mainboard

Learn More -

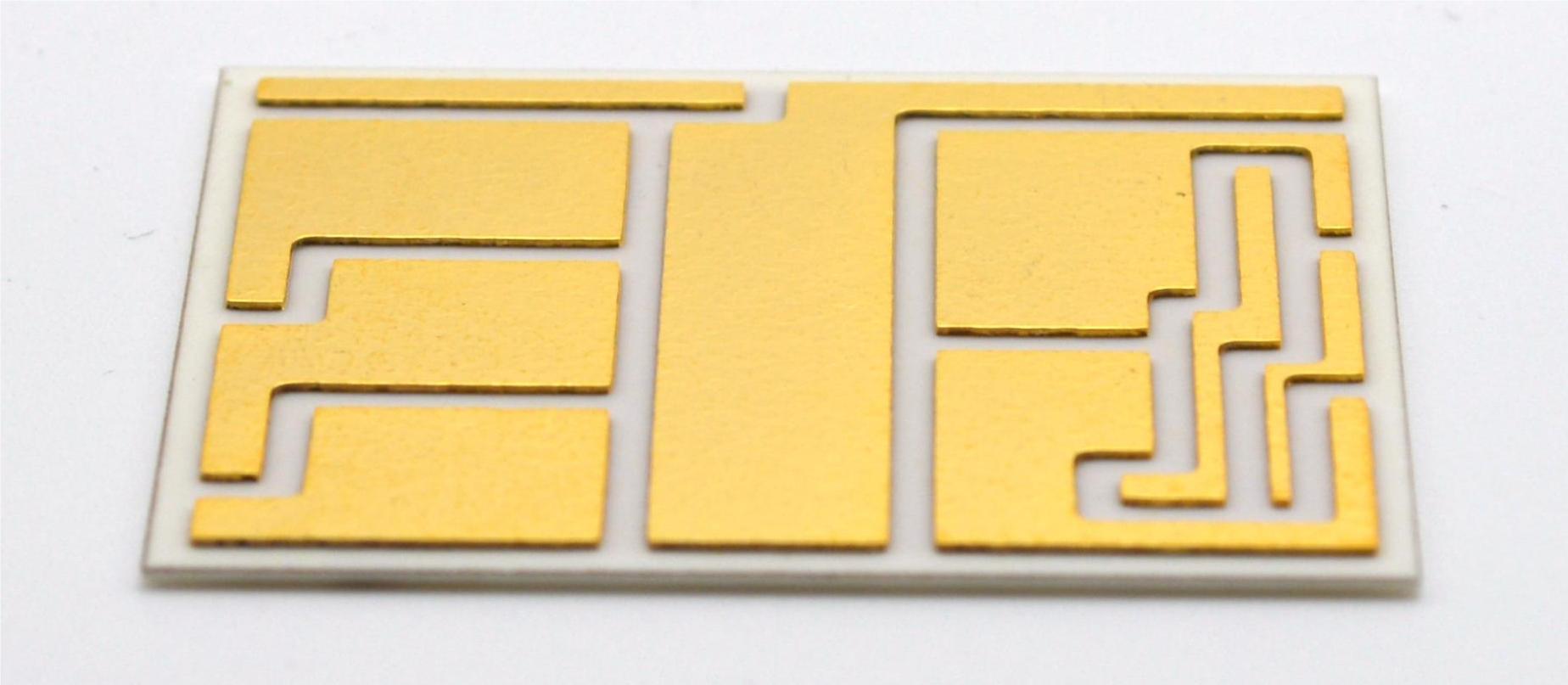

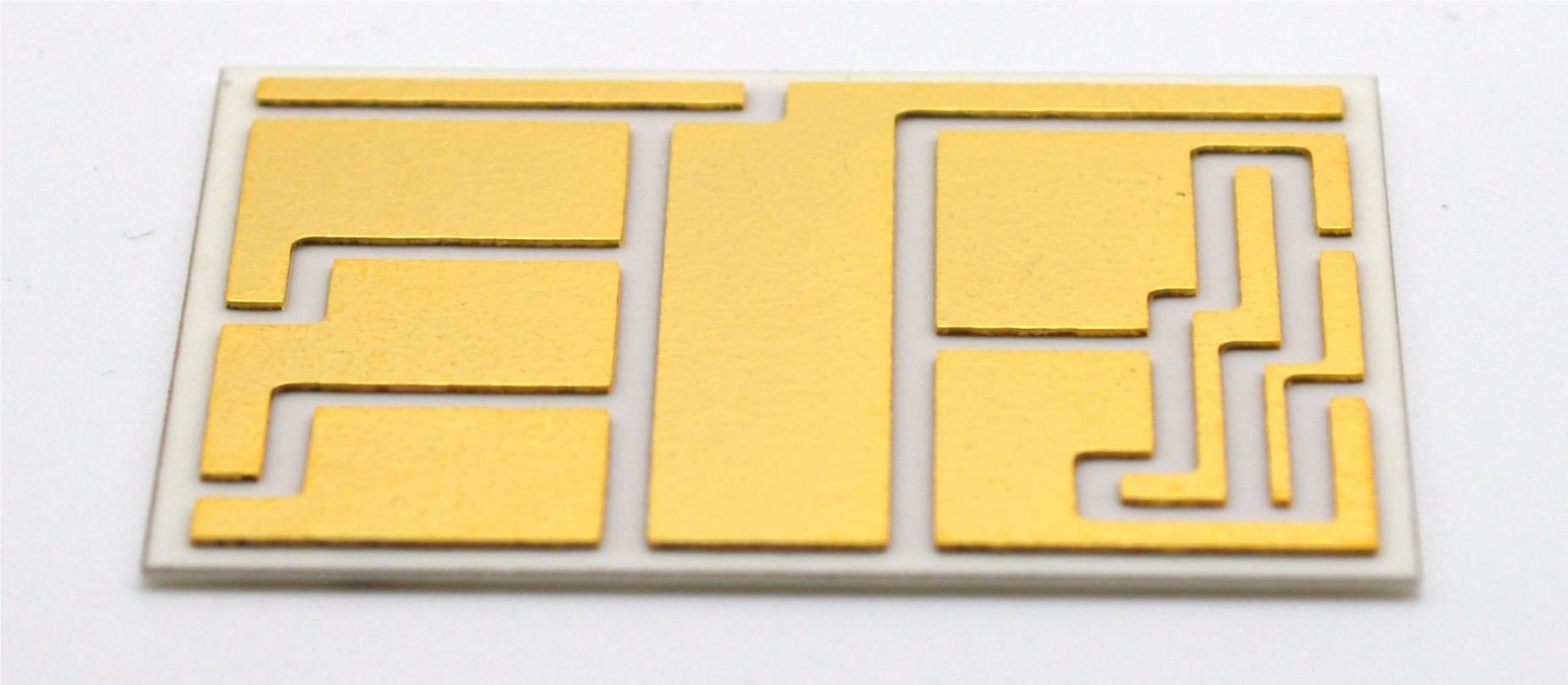

Exploring the Applications of Al₂O₃ Ceramic PCBs in Modern Industries

20 Nov, 2025

The application of Al₂O₃ ceramic PCBs is transforming industries with their unique features. They enhance LED lights, power devices, and fast signal systems. These PCBs excel in thermal management as they efficiently dissipate heat. Additionally, they provide excellent electrical insulation to maintain signal integrity. Al₂O₃ ceramic PCBs are durable and can withstand harsh conditions, making them ideal… Continue reading Exploring the Applications of Al₂O₃ Ceramic PCBs in Modern Industries

Learn More -

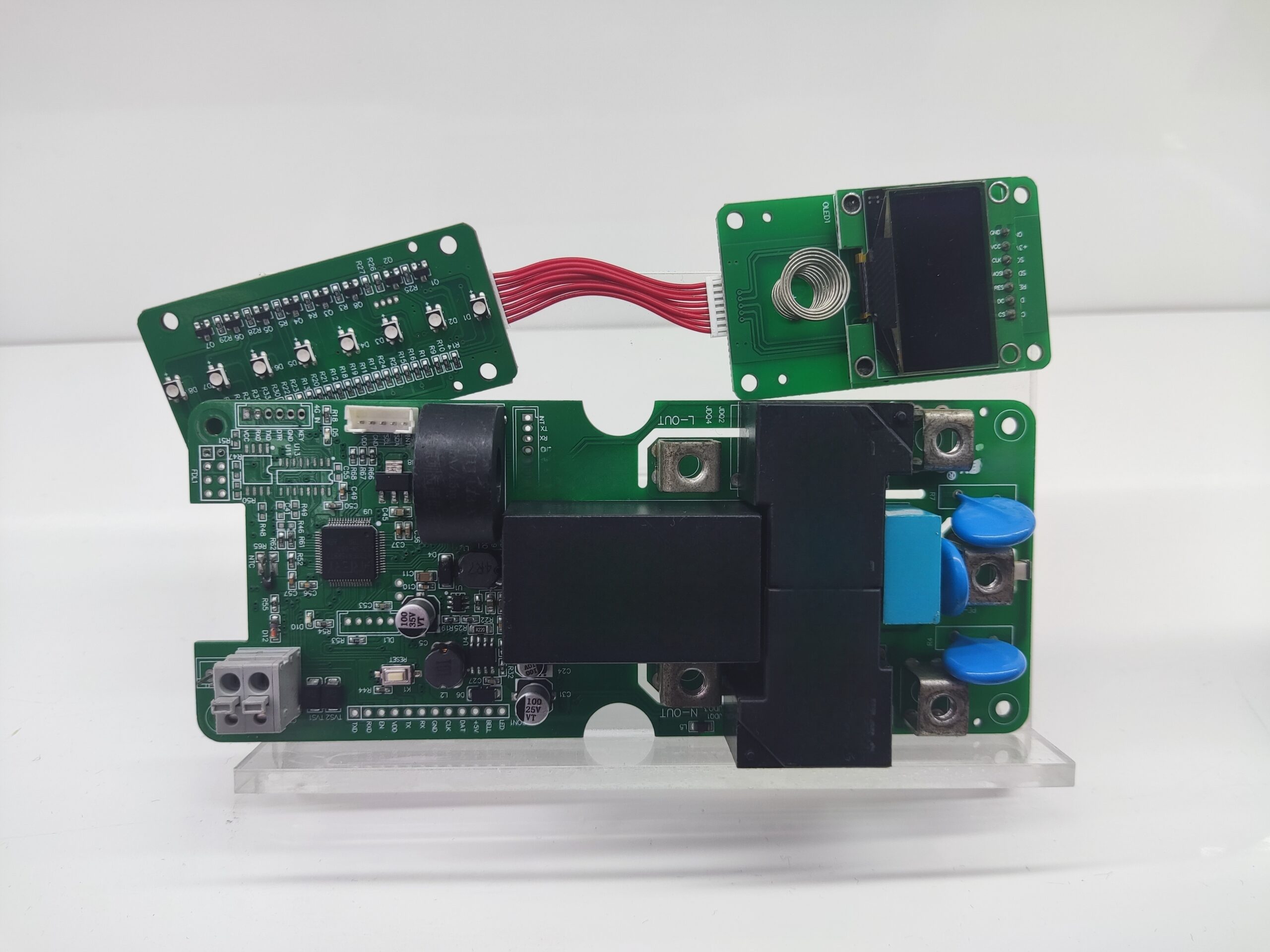

LTPCBA New Energy Portable Charging PCBA

19 Nov, 2025

As new energy vehicle charging demands grow increasingly diverse, users seek both “reliable fixed charging and convenient portable solutions.” Specializing in new energy PCBA manufacturing, LTPCBA presents its Portable Charging PCBA—a versatile, high-performance solution engineered to deliver safety and portability for both home wall-mounted installations and mobile charging applications. 1. Functional Innovation: Wide Compatibility &… Continue reading LTPCBA New Energy Portable Charging PCBA

Learn More -

Applications of Aluminum Nitride Ceramic PCBs in Modern Industries

19 Nov, 2025

Aluminum nitride ceramic PCBs are important in today’s industries, particularly due to the application of AIN (Aluminum nitride) ceramic PCB technology. They enhance the performance of electronic components by providing excellent heat management, with thermal conductivity ranging from 120 to 200 W/mK. This capability ensures that high-power systems remain cool and operate efficiently. Additionally, they prevent electrical… Continue reading Applications of Aluminum Nitride Ceramic PCBs in Modern Industries

Learn More