News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

2+N+2 or Other HDI PCB Stackups Which Is Best for Your Project

12 Nov, 2025

Choosing the right HDI PCB stackup depends on your project’s needs. The hdi pcb 2 n 2 stackup works well for high-density interconnects in mobile, networking, aerospace, and medical devices. You can see how different projects benefit below: Project Type Description Mobile Devices Ideal for smartphones and tablets requiring compact designs with high routing density. Networking… Continue reading 2+N+2 or Other HDI PCB Stackups Which Is Best for Your Project

Learn More -

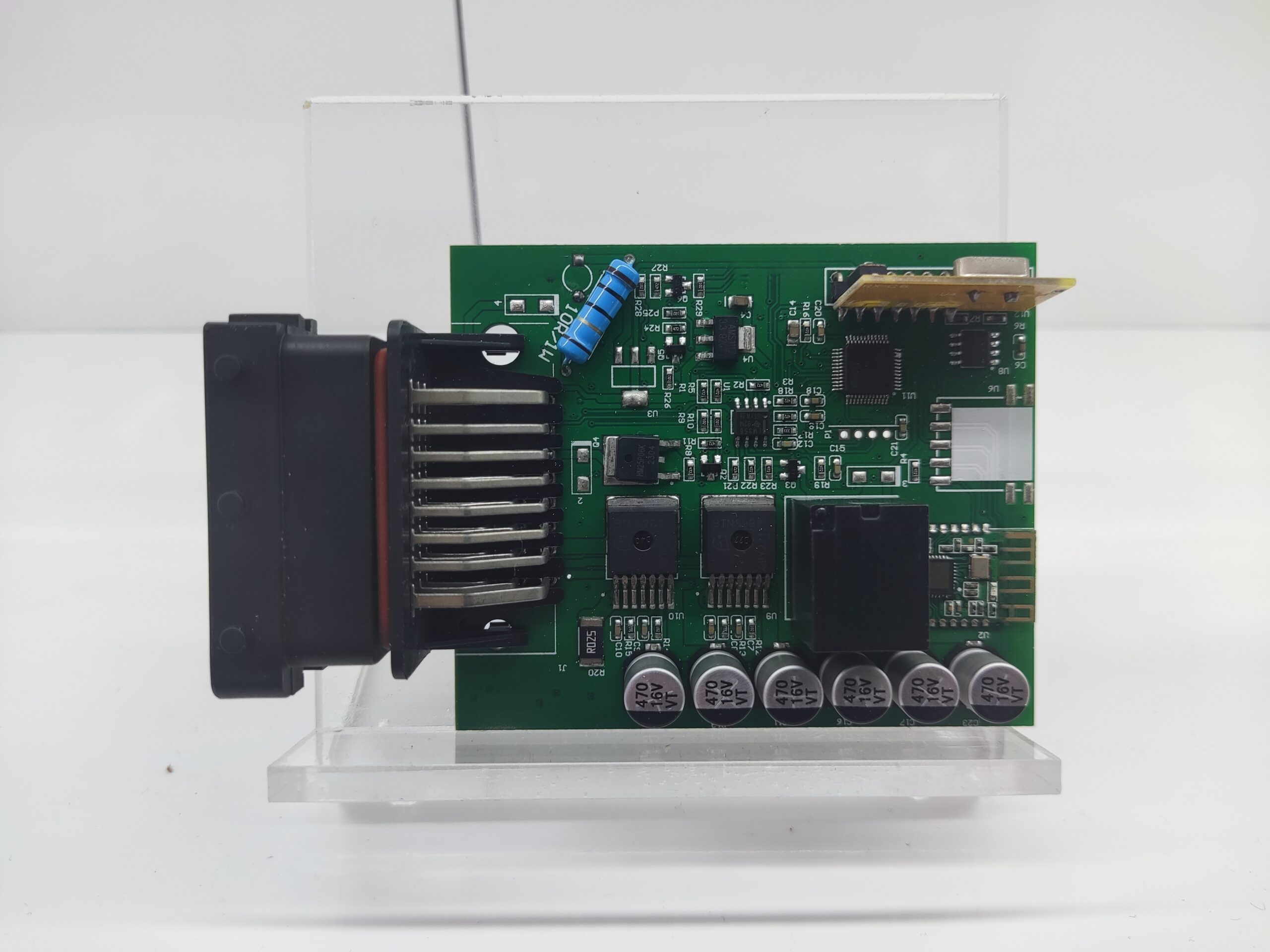

LTPCBA Automotive Motor PCBA

11 Nov, 2025

As the demand for automotive intelligent upgrades surges, the power tailgate aftermarket requires core control components that meet exceptionally high standards for performance and reliability. LTPCBA, a specialized manufacturer in automotive-grade PCBA, introduces its Automotive Motor PCBA. Designed with automotive-grade principles and precision manufacturing, it serves as the intelligent core for power tailgate systems, delivering… Continue reading LTPCBA Automotive Motor PCBA

Learn More -

Key Advantages and Performance Features of Ultra HDI PCBs

11 Nov, 2025

Ultra hdi pcb technology offers unique advantages over standard options. Electronics professionals are witnessing rapid adoption of ultra hdi pcb due to several factors: Key Takeaways # Ultra HDI PCBs enable higher component density, allowing for more functions in smaller devices, which is essential for modern electronics. # These boards improve signal integrity by reducing crosstalk and… Continue reading Key Advantages and Performance Features of Ultra HDI PCBs

Learn More -

What is Any Layer HDI PCB and What Makes It Unique

10 Nov, 2025

You can use any layer hdi pcb for advanced electronics that require tight spacing and superior performance. This technology allows microvias to connect any two layers, setting any layer hdi pcb apart from traditional HDI PCBs. Feature Any Layer HDI PCB Traditional HDI PCB Layer Connections Microvias between any layers Limited via options Trace Spacing… Continue reading What is Any Layer HDI PCB and What Makes It Unique

Learn More -

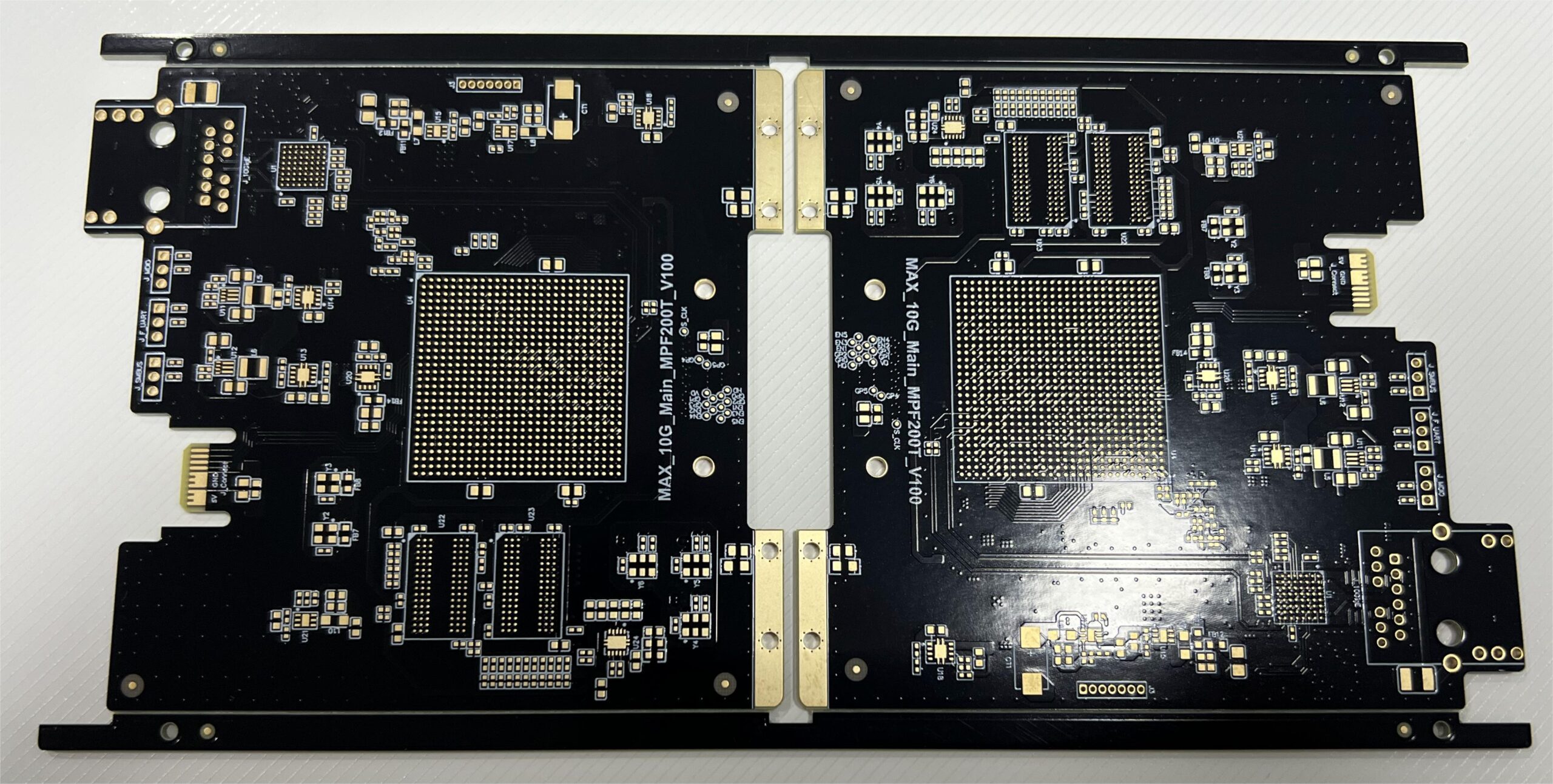

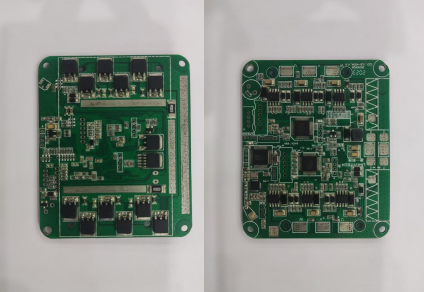

LTPCBA High-Density Control & Power Drive PCBA: Redefining Industrial-Grade Integration for Smart Control Applications

10 Nov, 2025

As an established PCBA manufacturer, LTPCBA is proud to introduce our latest high-density Control and Power Drive PCBA — a fully integrated solution engineered with intelligent layered design, functional zoning, and industrial-grade components. Designed to serve as the core control platform for demanding applications such as industrial automation, automotive systems, and advanced equipment, this PCBA… Continue reading LTPCBA High-Density Control & Power Drive PCBA: Redefining Industrial-Grade Integration for Smart Control Applications

Learn More -

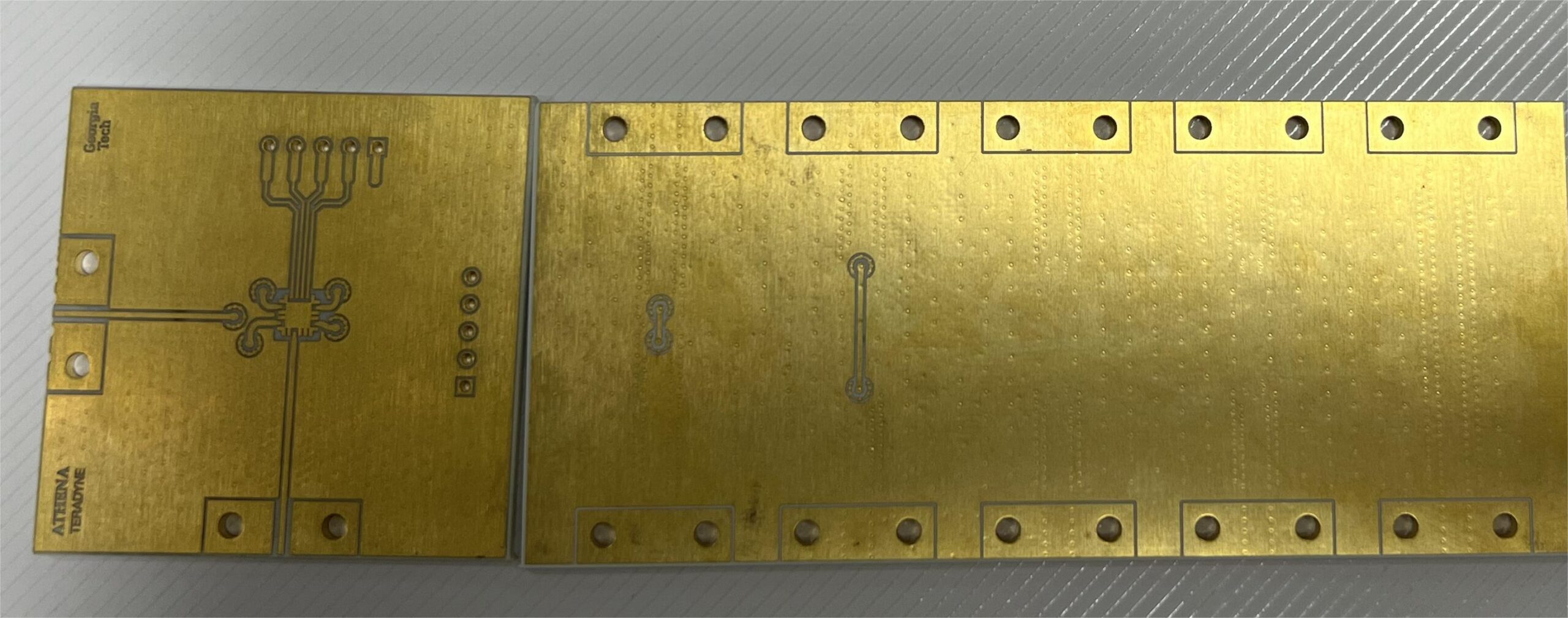

LTPCBA Multimedia Data Interaction PCBA

10 Nov, 2025

As a professional PCBA manufacturer, LTPCBA is proud to introduce our latest Multimedia Data Interaction PCBA module. Engineered with high integration, multi-interface compatibility, and reliable manufacturing processes, this module serves as the “Intelligent Interaction Hub” for consumer electronics, industrial equipment, and IoT devices. Here’s a detailed look from three key perspectives: 1. Technical Design: Highly… Continue reading LTPCBA Multimedia Data Interaction PCBA

Learn More