News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

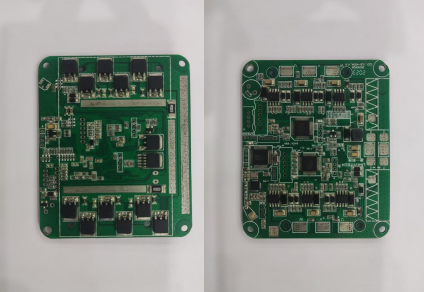

LTPCBA High-Density Control & Power Drive PCBA: Redefining Industrial-Grade Integration for Smart Control Applications

10 Nov, 2025

As an established PCBA manufacturer, LTPCBA is proud to introduce our latest high-density Control and Power Drive PCBA — a fully integrated solution engineered with intelligent layered design, functional zoning, and industrial-grade components. Designed to serve as the core control platform for demanding applications such as industrial automation, automotive systems, and advanced equipment, this PCBA… Continue reading LTPCBA High-Density Control & Power Drive PCBA: Redefining Industrial-Grade Integration for Smart Control Applications

Learn More -

LTPCBA Multimedia Data Interaction PCBA

10 Nov, 2025

As a professional PCBA manufacturer, LTPCBA is proud to introduce our latest Multimedia Data Interaction PCBA module. Engineered with high integration, multi-interface compatibility, and reliable manufacturing processes, this module serves as the “Intelligent Interaction Hub” for consumer electronics, industrial equipment, and IoT devices. Here’s a detailed look from three key perspectives: 1. Technical Design: Highly… Continue reading LTPCBA Multimedia Data Interaction PCBA

Learn More -

How to Evaluate Turnkey PCBA Manufacturing Partners for Quality and Speed

07 Nov, 2025

To evaluate pcba turnkey manufacturing partners, you should focus on end-to-end process management, certifications, technical capabilities, supply chain strength, customer service, and proven fast delivery. Top turnkey pcb assembly providers achieve higher quality and speed than industry averages. Metric LTPCBA Performance Industry Average Lead Time Reduction Up to 60% faster 20–30% faster First Pass Yield… Continue reading How to Evaluate Turnkey PCBA Manufacturing Partners for Quality and Speed

Learn More -

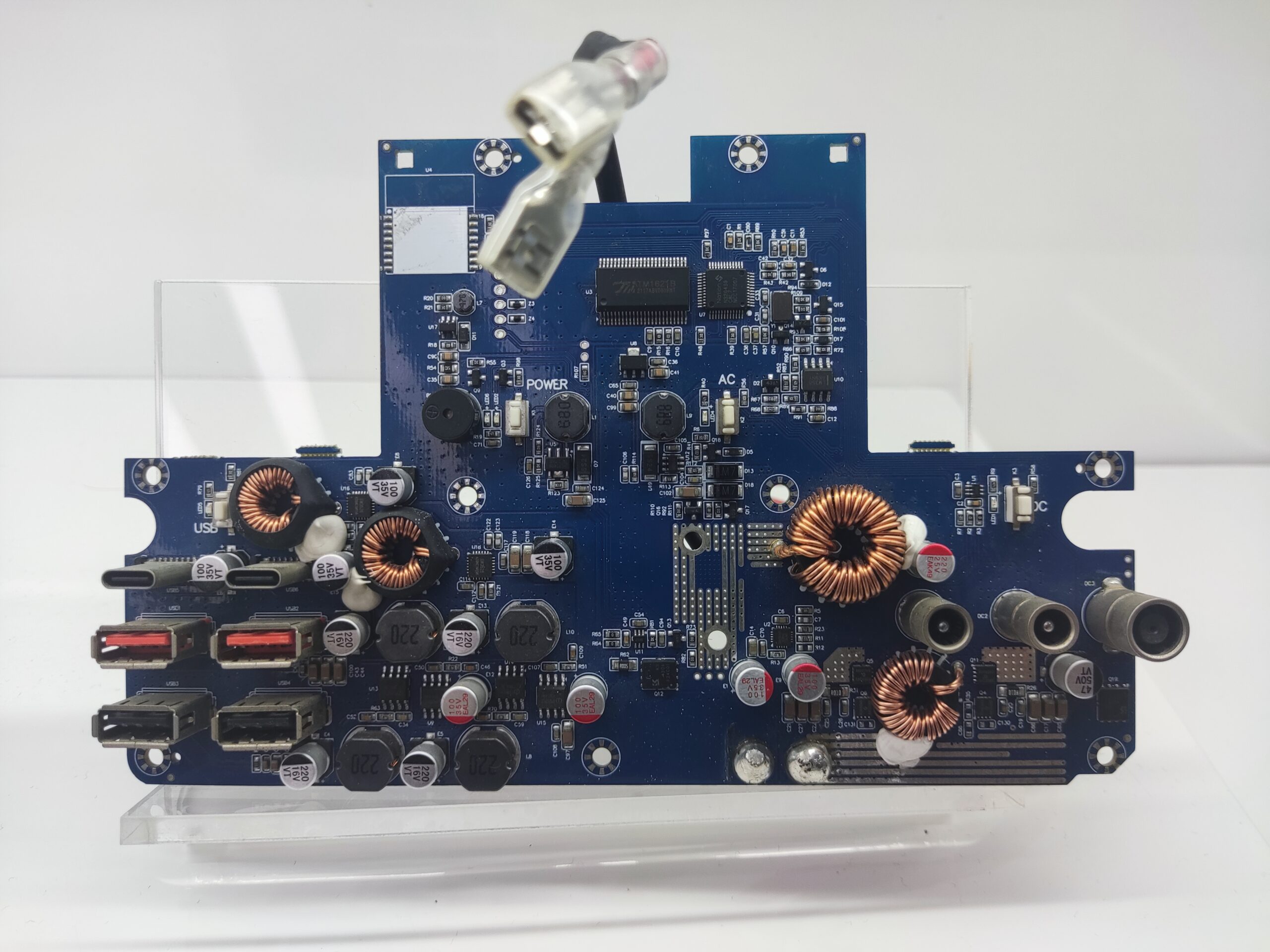

LTPCBA Portable Power Station PCBA

06 Nov, 2025

In critical scenarios like field operations, emergency maintenance, and vehicle rescue, power interruption often means operational halt or elevated risks. As a specialized manufacturer in new energy PCBA solutions, LTPCBA introduces its Portable Power Station PCBA — engineered to deliver versatile output, extended battery life, and lightweight portability. Serving as the central “power hub” for… Continue reading LTPCBA Portable Power Station PCBA

Learn More -

What is PCBA Traceability and Why Does It Matter

06 Nov, 2025

PCBA traceability allows you to monitor every stage of the PCBA process, from sourcing raw materials to delivering finished products. This system provides enhanced quality assurance and process optimization, ensuring that each step is documented and verifiable. Comprehensive pcba traceability reports give you greater confidence in your PCBA, especially when strict industry standards must be met. At LTPCBA,… Continue reading What is PCBA Traceability and Why Does It Matter

Learn More -

LTPCBA Multimedia Data Interaction PCBA

05 Nov, 2025

As a professional PCBA manufacturer, LTPCBA is proud to introduce our latest Multimedia Data Interaction PCBA module. Engineered with high integration, multi-interface compatibility, and reliable manufacturing processes, this module serves as the “Intelligent Interaction Hub” for consumer electronics, industrial equipment, and IoT devices. Here’s a detailed look from three key perspectives: 1. Technical Design: Highly… Continue reading LTPCBA Multimedia Data Interaction PCBA

Learn More