News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

How to connect FPC in place of traditional cables for better performance

23 Oct, 2025

Replacing traditional cables with FPC can make your device work better. FPCs are smaller and lighter than traditional cables. They help your device last longer and work more reliably. Many engineers notice fewer problems with connections after they replace traditional cables with FPC. You also get more room inside your device. This helps you make… Continue reading How to connect FPC in place of traditional cables for better performance

Learn More -

How to choose the right PCB and EMS solutions for smart home products

22 Oct, 2025

Imagine you want to make a new smart home device. You will face many problems when picking a good company to build it. You must check that your PCB / EMS Requirements for Smart Home Products fit your plans. Think about these common problems: You should find people with experience, good supplier networks, and clear talk.… Continue reading How to choose the right PCB and EMS solutions for smart home products

Learn More -

What is Package on Package Technology and How Does It Work

22 Oct, 2025

Package on package technology lets you stack package on package circuit packages on top of each other. You often see package on package in devices where a CPU or system on a chip is at the bottom, with RAM placed on top. This package on package setup saves space and allows you to put strong logic… Continue reading What is Package on Package Technology and How Does It Work

Learn More -

How Artificial Intelligence Makes EMI Testing Easier for Engineers

22 Oct, 2025

Artificial intelligence is transforming how to simplify EMI testing with artificial intelligence by providing engineers with advanced tools. These tools enhance automation, accuracy, and efficiency in the testing process. Many engineers face high costs and strict compliance regulations, and traditional EMI testing methods often struggle to detect errors. Rapid technological advancements, such as 5G and IoT, add to… Continue reading How Artificial Intelligence Makes EMI Testing Easier for Engineers

Learn More -

Essential Protection Technologies for Performance and Safety

21 Oct, 2025

Power Supply PCB Protection Techniques in 2025 use smart AI monitoring, green materials, and smaller designs to give better results. These new ideas make electronics safer, more reliable, and save energy. Key Takeaways # AI monitoring helps find problems in PCBs early. It also lowers costs for making PCBs. # Using eco-friendly materials makes PCBs… Continue reading Essential Protection Technologies for Performance and Safety

Learn More -

Power Supply PCB 2: Best Methods for Testing, Troubleshooting, and Repair

21 Oct, 2025

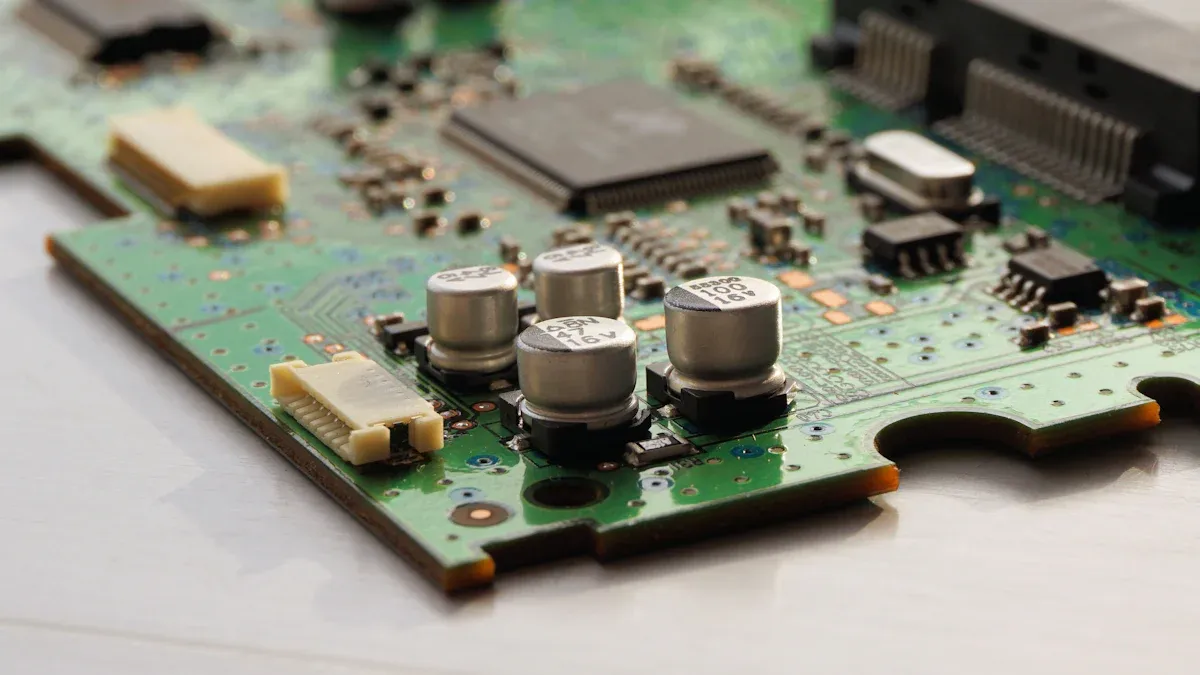

When you have a broken power supply PCB, you want safe and good repairs. You can do better if you follow steps in order. First, look at the board to see burnt parts or bad solder. Next, check the power and test each part, like ICs and capacitors, with the right tools. Careful Testing & Troubleshooting of… Continue reading Power Supply PCB 2: Best Methods for Testing, Troubleshooting, and Repair

Learn More