Industry-benchmark 48-hour HDl delivery commitment, intelligent production scheduling svstem and eficient supply chain collaboration,seamless connection from order receiving to shipment throughout the entire process, pressing the accelerator for your urgent projects.

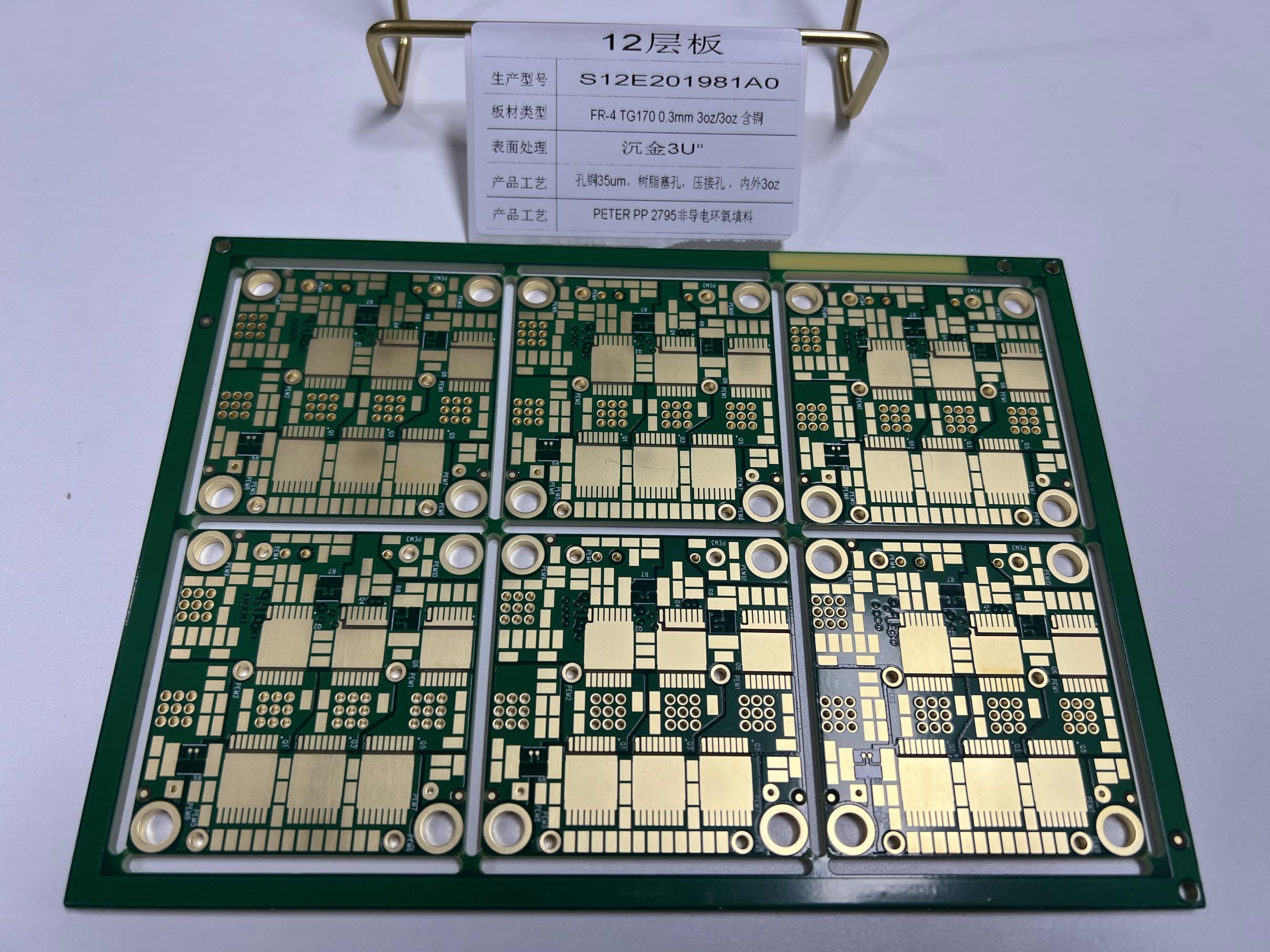

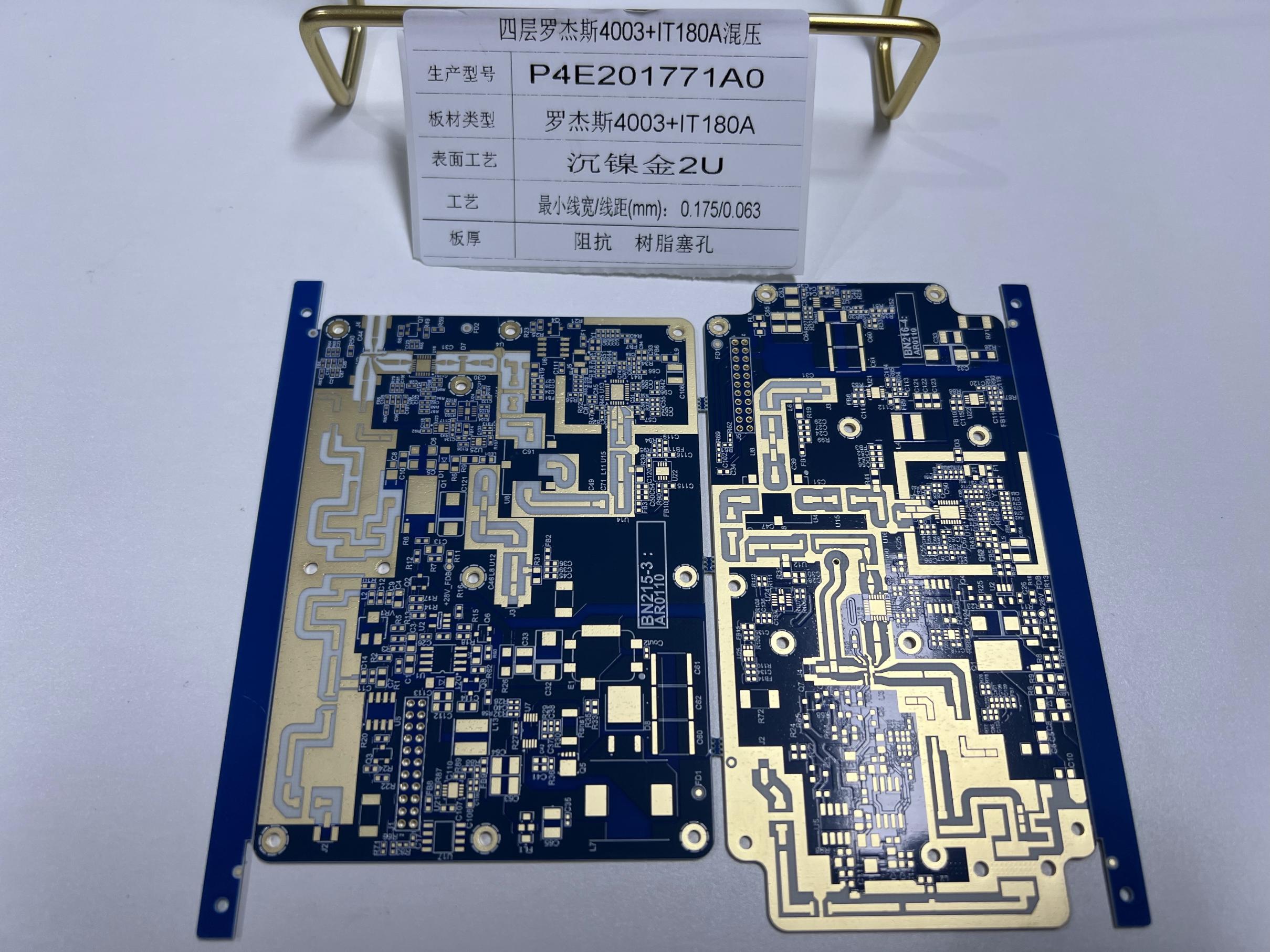

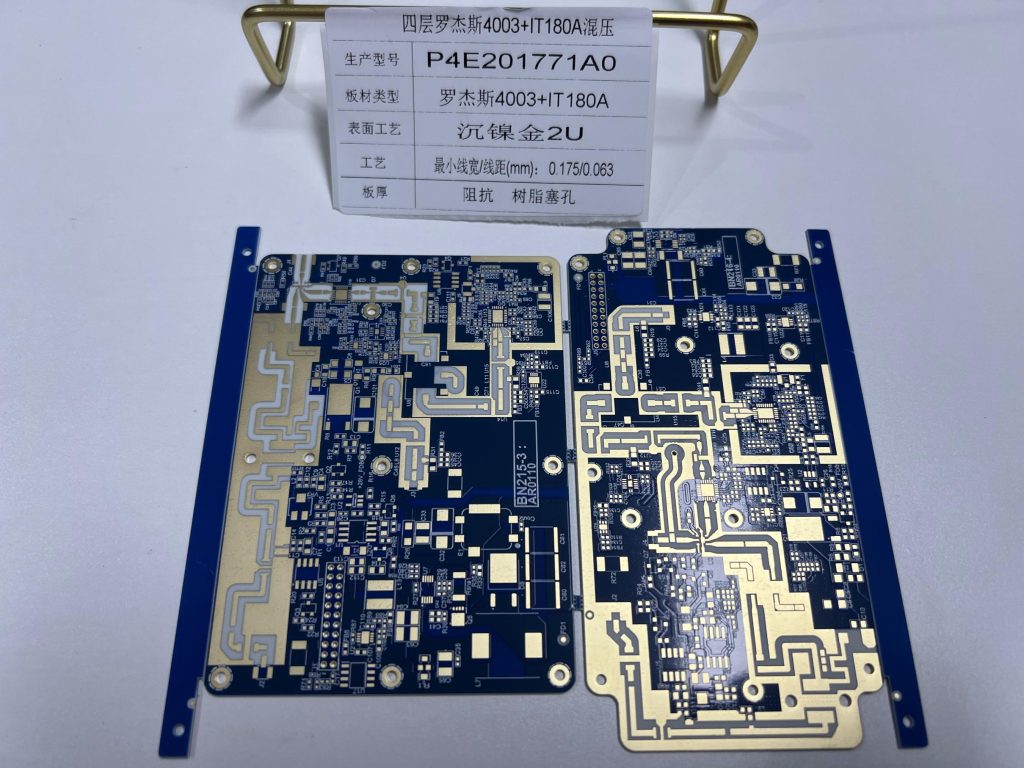

Integrating various high-quality raw material resources from around the world, covering high-frequency boards, halogen free and environmentally friendly materials, etc., it supports customized material selection to meet the strict demands of multiple fields such as 5G communication and automotive electronics.

From design and development to finished product assembly, itis 100% completed in our own factory. Equipped with aninternationally leading production equipment matrix, itensures process accuracy and delivery stability, and flexiblyresponds to diverse order demands.

We have established a matrix of world-class production equipment, safeguarding the manufacturing of HDl circuit boards with precise technology.Our circuit LDl and solder Mask LDl enable high-precision patern fabrication; the two-fuid etching Es ensures accurate circuit formation; and theonline AOl conducts realtime defect detection. The horizontal copper deposition line and Vcp vertical electroplating line guarantee the quality ofmetallization and surface treatment, while the Laser sikscreen printer completes product identification. With seamless coordination across allproduction stages, our equipment system prioritizes both quality and efficiency, frmly positioning us at the forefront of the industry.

Hitachi's laser drill crushes HDI production! It nails micro via precision, zipping through copper/resin with tight tolerances. Handles diverse hole sizes, maintains consistency across high-density layouts. Fast, reliable, and built to ace the intricate demands of HDI PCB manufacturing.

We have two VCP production lines, one for through-hole copper plating and the other for laser hole filling of HDI products. We use the most advanced equipment in China, ensuring uniform copper plating with good uniformity, which provides a stable foundation for subsequent production.

Our online AOI for PCB etching can inspect line defects with extremely high precision. Its automatic sorting arm can pick quickly, greatly reducing manual work. The output has been increased, errors have been reduced, and the yield rate of finished products has been greatly improved.

Our flying probe test department runs on all-screw machines—total workhorses. High precision, blazing speed, including 8-probe setups. They crank up efficiency for fast turnaround, nailing quality checks while slashing lead times. Perfect for keeping your PCB deliveries on point.

We have multiple linear motor drilling machines with a minimum drilling hole diameter of 0.1MM, including high-performance depth control drilling machines for back drilling, which are fast and highly precise, suitable for high-difficulty products such as HDI and rigid-flex PCBS.

Silkscreen Printer has higher precision, with a resolution of up to 0.05mm. The character edges are clear, which can meet the fine marking requirements of high-density PCBS. It is more efficient for small-batch and multi-variety order switching and shortens the production change time.

For Immersion copper , we adopt a Horizontal Electroless Copper Plating line. Its advantages include good uniformity, high continuous production efficiency, strong adaptability suitable for different materials and high-precision products such as HDI, and a high degree of automation, reducing reliance on personnel.

"Both our circuit and solder mask production lines use LDI exposure machines, cutting down on film usage and management. With laser imaging resolution down to 0.05mm, they boost efficiency and reduce waste."

We have established a multi-dimensional quality assurance system: At the equipment level,we have introduced advanced testing equipmentsuch as online A0l and fying probe testers to achieve precise monitoring throughout the entire process; At the management sytem level,international certifications such as 1s0 9001, Ul, and T16949 have been passed, and a standardized control process from raw materialwarehousing to finished product outbound has been established. At the personnel allocation level, a professional quality inspection team and achemical laboratory technical group have been formed, Bv integrating inteligent algorithms with manwal re-inspection, the accuracy compliancerate of HDl products exceeds 99.8%, setting a quality benchmark with a full-chain guarantee force.

Professional chemical laboratories strictly control the quality of chemical reagents or the production line.Through scientific methods such as spectral analysis and component titration, they ensure that every drop of reagent meets the process standards,guaranteeing product quality from the source.

By using multiple methods such as flying probe testing, test fixture testing, four-wire testing, and appearance testing, the electrical performance,soldering quality, and circuit integrity of HDl circuit boards are comprehensively inspected to ensure that the products are 100% qualified before leaving the factory.

Equipped with high-precision flying probe testers,intelligent AOl optical inspection instruments, optical microscopes, impedance testers, hole copper testers, AVl and other professional equipment, from raW material entry to finished product exit,360 all-round inspection is carried out, leaving no minor defects overlooked.

Our HDI products account for more than 60% of the company’s production capacity. Relying on the full-process in-house production system, we have accumulated rich experience In special processes (such as arbitrary order interconnection, laser blind buried holes, etc.). Each month, more than 6,000 part numbers are delivered from the factory, covering multiple fields such as communication, automobiles, and medical care. Our professional engineering team possesses strong technical processing capabilities. From complex designs to urgent orders, we can efficiently implement processes. With large-scale production capacity and refined technology, we meet the diverse needs of global customers.

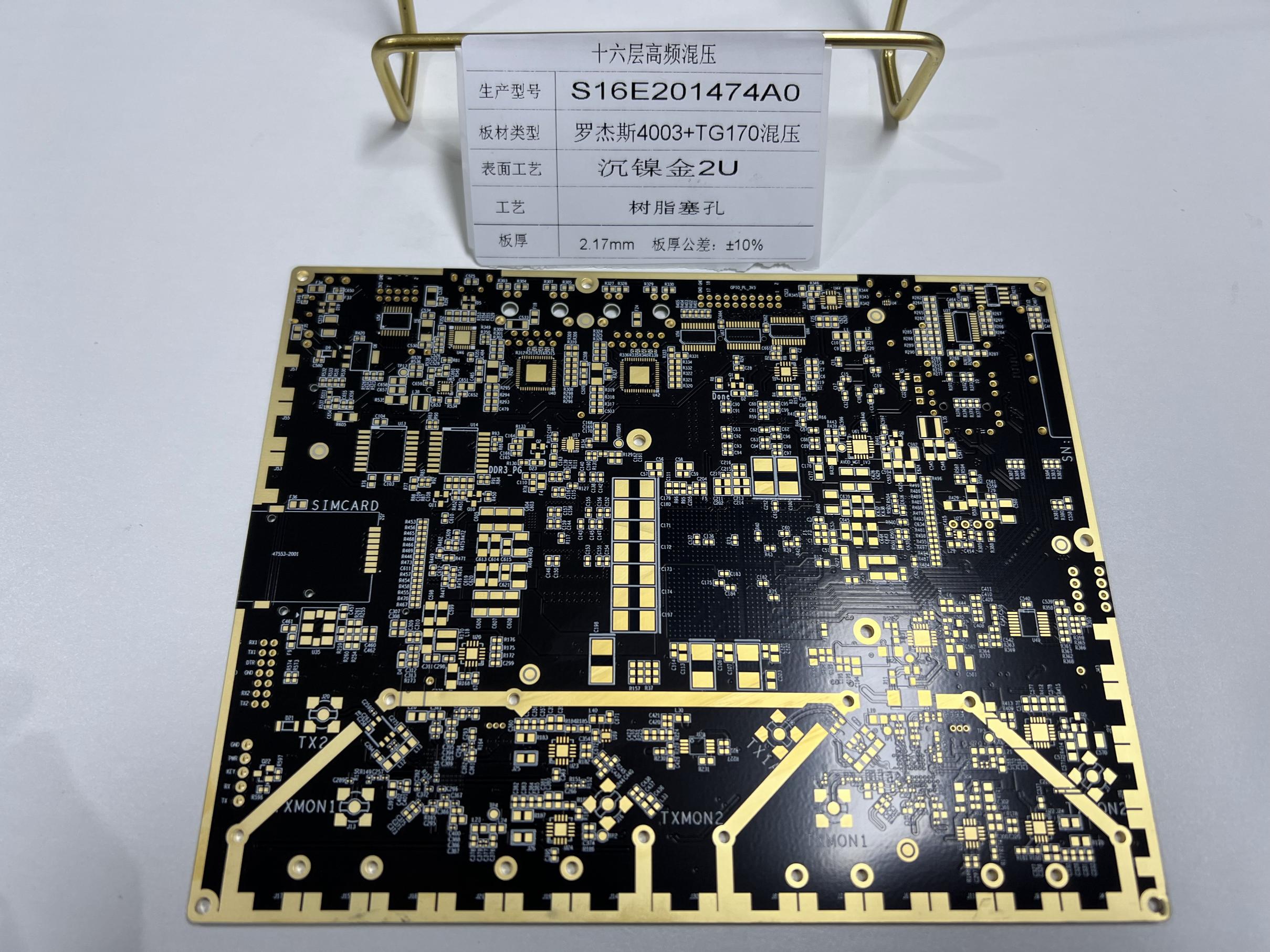

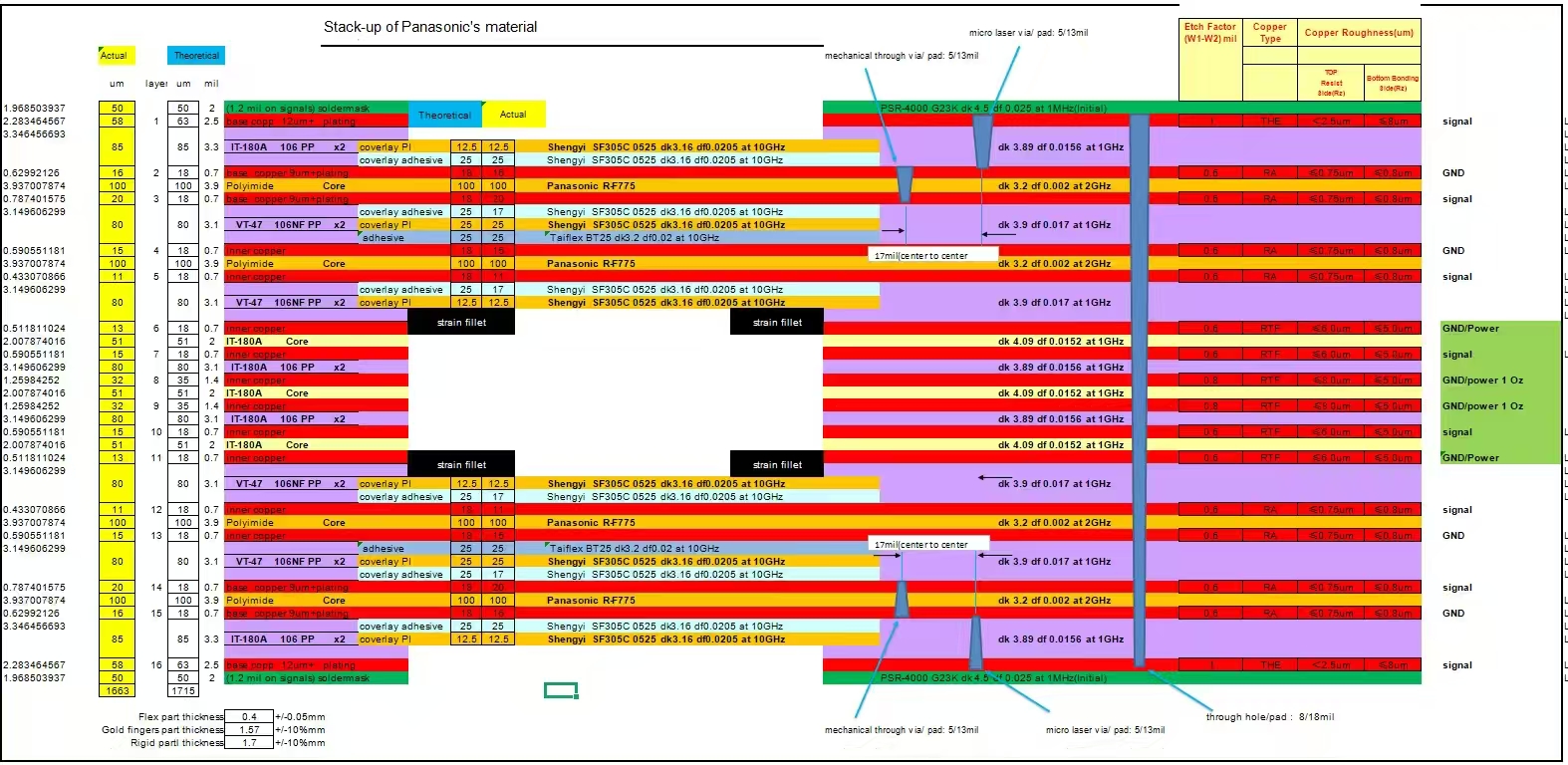

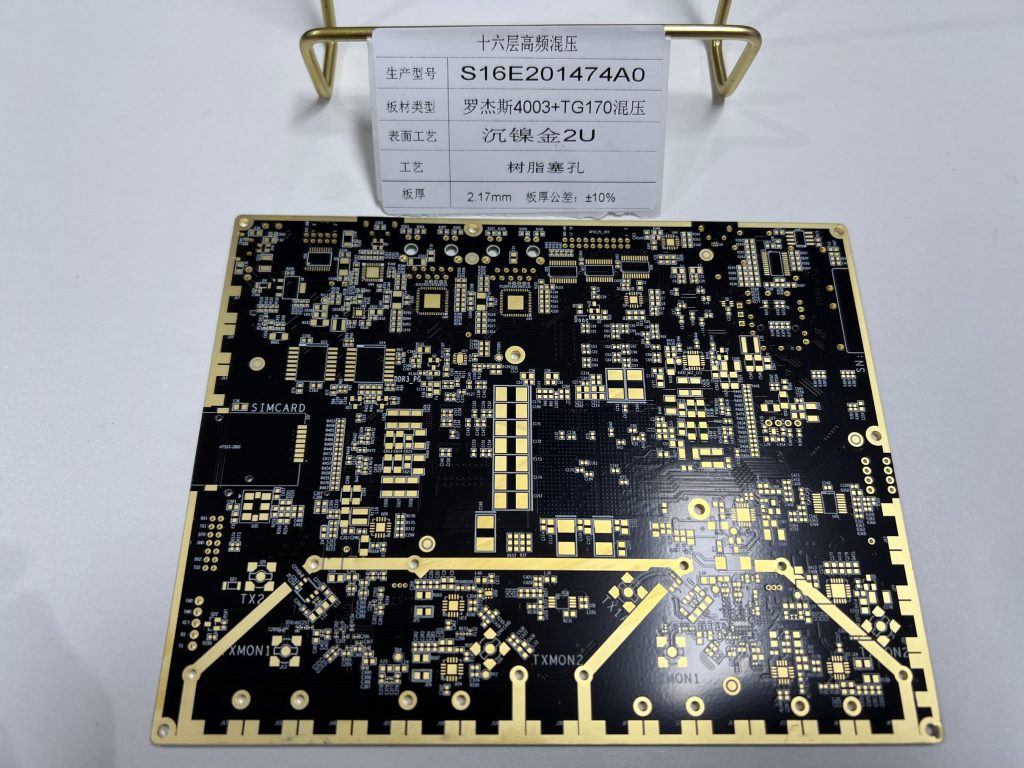

This product is a 16-layer high-frequency HDI product that combines software and hardware. Its special structure is complex. The multi-layer stacking includes various functional layers such as the signal layer, ground layer (GND), and Power layer (GND/ POWER). The large number of layers increases the difficulty of processes such as interlayer alignment and lamination, and it is also difficult to control the material properties. A variety of materials with different properties, such as Panasonic RF775 and Shengyi SF305C, were used. Each material has different parameters such as dielectric constant (dk) and tangent of loss Angle (df). In a high-frequency environment, it is necessary to precisely control the material properties to meet the electrical performance requirements. The differences in the coefficients of thermal expansion between materials can also easily lead to problems such as warping. The through-hole process has high requirements. There are mechanical through via and micro laser via. The production of micro laser via requires high-precision processes such as laser drilling, and has extremely high requirements for equipment and process control. The hole diameter and hole wall quality of mechanical through via also affect the reliability of electrical connections.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

High-density interconnect, or HDI, circuit boards are printed circuit boards with a higher wiring density per unit area than traditional printed circuit boards. In general, HDI PCB is defined as PCBs with one or all of the following: micro via; blind and buried vias; built-up laminations, and high signal performance considerations. Printed circuit board technology has been evolving with changing technology that calls for smaller and faster products. HDI boards are more compact and have smaller vias, pads, copper traces, and spaces. As a result, HDIs have denser wiring resulting in lighter weight, more compact, lower layer count PCBs. Rather than using a few PCBs in a device, one HDI board can house the functionality of the previous boards used.

HDI requires the latest advances in the PCB interconnection technology: With the latest state of the art HDI technology, HDI PCBs can be defined as those printed circuit boards that make use of some or all of the following features; Blind and buried via or micro via techniques, high signal performance considerations, micro vias, and built-up standard PCB laminations. Higher connection pad densities or HDI technology came into the limelight close to the end of the 20th century. Its popularity grew tremendously due to the numerous advantages it holds over traditional PCBs. The advanced multilayer deployed by HDI printed circuit manufacturing allows you to integrate multiple layers to create a multi-layered PCB.

In HDI PCB, micro-vias interconnect HDI substrates and printed circuit board layers to adapt to the high input/output (I/O) density of advanced packaging. HDI utilizes this micro via geometric structure finer lines technology to make circuits that can improve the efficiency of assembly and space utilization and is also necessary for the miniaturization of electronic products in fewer layers.

The following are the three major areas in which you can see variations between ordinary and HDI PCBs:

· The density of the circuit – When the designers build HDI PCBs, they often choose to cover the wires that link to the next layer. You can use micropore processing to do this. It will allow you to maximize the PCB circuit density, which can be useful for small electronic applications.

· Manufacturing technology – HDI PCBs are once again relying on advanced micropore technology, particularly in comparison to the traditional drilling procedures that standard PCBs utilize during manufacturing.

· Electrical performance and signal – HDI PCBs micropore contacts lead to a high level of interruption security, which provides safety from signal interferences. It is one reason you can improve the performance of an HDI board over a raw PCB.

Generally, HDI circuit boards have the following advantages:

Reduce the PCB cost: When the density of printed circuit board increases by more than eight layers, it will be manufactured by HDI high-performance thin materials, and its cost will be lower than the traditional complicated lamination process Increase circuit density: The interconnection of traditional circuit boards and parts must be connected through the lines and via-hole conductors drawn out around the QFP (fan-in and fan-out), so these circuits need to occupy some space.

The micro via technology can hide the wiring required for interconnection to the next layer. The connection between the pads and the leads between different levels is directly connected by the blind holes in the pads, without the need for fan-in and fan-out wiring. Therefore, some pads (such as mini-BGA or CSP small ball bonding) can be placed on the outer layer board to accept more parts, which can increase the density of the circuit board. Many high-function small-sized wireless phone handset boards use this new stacking and wiring method. Conducive to the use of advanced assembly technology:

Generally, the traditional drilling technology cannot meet the needs of small parts of the new generation of thin circuits due to the size of the pad (through-hole) and mechanical drilling. With the advancement of micro via technology, designers can design the latest high-density IC packaging technology, such as Array package, CSP, and DCA (Direct Chip Attach), into the system. Better electrical performance and signal accuracy:

The use of micro-hole interconnects can reduce signal reflection and cross-talk interference between circuits, and allow more space for the circuit board design. Due to the physical structure of the micro-holes, The nature is that the holes are small and short, so the effects of inductance and capacitance can be reduced, and the switching noise during signal transmission can also be reduced. Higher reliability: Due to the thinner thickness and aspect ratio of the micro-holes, the reliability of signal transmission is higher than that of ordinary through-holes.Improved thermal properties:

he insulating dielectric material of HDI boards has a higher glass transition temperature (Tg), so it has better thermal properties. Improve radio frequency interference/ electromagnetic wave interference/electrostatic discharge (RFI/ EMI/ ESD): micro via technology can allow circuit board designers to shorten the distance between the ground layer and the signal layer to reduce radio frequency interference and electromagnetic wave interference; on the other hand, the number of ground wires can be increased to avoid damage to the parts of the circuit due to the instantaneous discharge caused by static electricity accumulation.

The micro via technology allows the circuit to be arranged on the inner layer so that the circuit designer has more design space, so the efficiency in circuit design can be higher.

HDI boards are appropriate for a wide range of industries. As mentioned above, you’ll find them in all types of digital devices mobile devices, mobile phones, digital cameras, laptop computers, tablets, and more components where miniaturization is key to the effective application of the product. You can also find high-density interconnect PCBs in automobiles, aircraft, and other vehicles that rely on electronics. One of the most critical areas where the high-density PCB is making huge inroads is in the medical arena. Medical devices frequently need small packages with high transmission rates that only HDI PCBs can supply.

For example, an implant needs to be small enough to fit in the human body, but any electronics involved in that implant absolutely must efficiently allow for high-speed signal transmission. Here, the HDI PCB indeed is a godsend. HDI PCBs can also be useful in other medical equipment, like emergency room monitors, CT scans, and much more. No matter your industry, you’re probably already getting some ideas about how high-density interconnect PCBs can make the electronics you produce or use even better – get in touch with us PCBCart to discuss it. We’ll let you know if you’re on the right track and help you decide exactly how beneficial an HDI PCB can be to your industry. Then, you can determine whether or not to take the next step.

There are mainly two HDI structures:

· Buildup

· Any-layer

The buildup structure, which is the basic structure of HDI PCB, uses mechanical drilling as well as laser drilling. Firstly, the core is laminated, drilled by mechanical drilling, plated, and filled. Subsequently, additional micro-via layers are added to the core, and then the drilling, plating, and filling processes are repeated. The buildup structure has a formula of N+C+N. N and C respectively represent the number of micro-via layers on either side of the core and the core. It has a through-hole via to connect outer surfaces and another one inside the core drilled before adding HDI layers. In the 2-layer of high-density interconnection, stacked micro-vias are copper-filled.

Any layer interconnection technology is an advanced technology used in HDI design. It is mainly for high-level interconnection applications since any of the two layers in the PCB can be interconnected without any restriction. In other words, any-layer technology has higher flexibility in the layout, which saves the PCB space at least 30%. However, due to its complexity regarding technology, the cost is higher than conventional buildup boards. Unlike the buildup structure, the micro-via is first drilled in the layer by laser drilling, followed by repeating processes of copper-plated, inner-layer image transfer and press, and the outer-layer imaging transferring finally.

LT PCBA is the leading expert at PCB design, embedded engineering, PCB manufacturing, and PCB assembly in China. We provide PCBs from a 2-50 layer for fabrication, which includes HDI, Flex, Rigid, multilayer PCB, and Rigid-flex boards. We also offer from low quantity to mass production, with high quality available at a low cost. So if you are looking to get the best and affordable HDI PCB manufacturing service, why don’t you order from LTPCBA. We can optimize your designs and calculate tolerances that will allow you to adjust the HDI PCB designs with high reliability. This, too, without influencing its fitness for your particular application.