Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By 管理

As the demand for automotive intelligent upgrades surges, the power tailgate aftermarket requires core control components that meet exceptionally high standards for performance and reliability. LTPCBA, a specialized manufacturer in automotive-grade PCBA, introduces its Automotive Motor PCBA. Designed with automotive-grade principles and precision manufacturing, it serves as the intelligent core for power tailgate systems, delivering stable, smart, and convenient aftermarket solutions.

1. Functional Matrix: Full-Range Automotive-Grade Intelligence

Built around the core concepts of **high performance, multi-mode interaction, and stable control**, this PCBA delivers a comprehensive functional system:

Core Computing & Communication: Powered by the APM32F103CBT6 automotive-grade MCU (an Arm® Cortex®-M3 based 32-bit microcontroller) from Geehy Semiconductor, it provides robust computational support for motor drive and logic operations. With integrated **CAN protocol communication**, it enables seamless interaction with the vehicle’s main system, ensuring precise control and harmonious operation between the original vehicle system and the smart tailgate.

Multi-Mode Interaction & Remote Control: Features **mobile app connectivity**, allowing users to monitor tailgate status and customize control logic in real-time. Equipped with a **433MHz remote control module**, it supports highly sensitive operation from up to **20 meters**, ensuring reliable activation even in complex electromagnetic environments or obstructed conditions.

2. Scenario Focus: Precision-Tailored for the Power Tailgate Aftermarket

This PCBA is custom-designed for the power tailgate aftermarket, supporting a wide range of vehicle models—from sedans and SUVs to commercial vehicles. It serves as the key link between the original vehicle circuit and the smart tailgate system, enabling effortless control upgrades that enhance convenience and technological appeal. For aftermarket manufacturers, it provides a reliable foundation for developing differentiated, high-performance smart tailgate products.

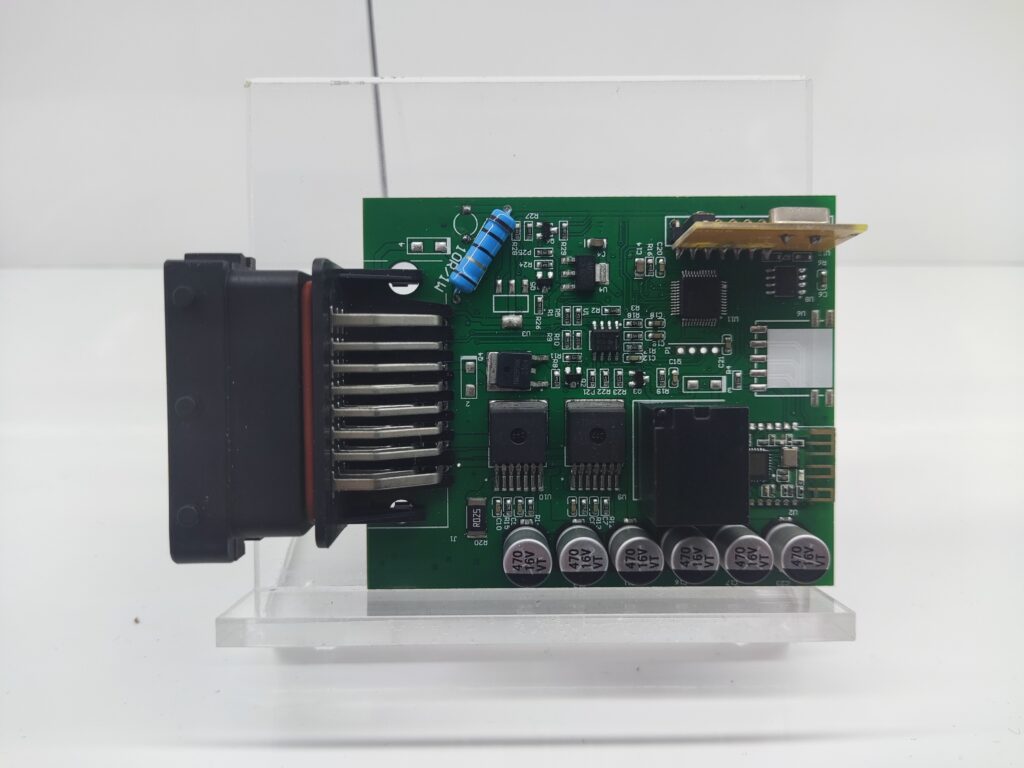

3. Component Design & Layout: Optimized for Performance and Space

The PCBA’s design reflects LTPCBA’s commitment to balancing performance, space efficiency, and reliability:

-Automotive-Grade Connectors: High-reliability connectors ensure stable electrical connections with both the vehicle circuit and tailgate motor, offering excellent resistance to vibration and EMI—ideal for challenging automotive environments.

Functional Zoning & Signal Integrity:The power module (including a multi-capacitor 470μF/16V filter section) is physically separated from the signal control zone (MCU, CAN transceiver, RF module), minimizing power noise interference. Shortened critical signal paths enhance transmission efficiency and control accuracy.

High-Integration Components: Space-optimized, automotive-grade components—such as the highly integrated MCU and compact 433MHz receiver module—enable a miniaturized PCB design that fits seamlessly into tight tailgate assembly spaces.

4. Manufacturing Process: Automotive-Grade Production for Reliable Performance

LTPCBA applies strict automotive-grade standards throughout the manufacturing process:

Automotive SMT & Soldering: Automotive-grade SMT equipment ensures **±0.02mm placement accuracy** for critical components like the MCU and communication chips. Precise thermal profiling during soldering guarantees strong, reliable solder joints that meet automotive durability requirements.

– **Comprehensive Testing & Validation:** Each PCBA undergoes end-to-end verification, including **automotive environmental tests** (thermal cycling, vibration, and shock), **CAN communication compatibility**, **remote sensitivity and range testing**, and **app functionality validation**, ensuring stable performance from **-40°C to 125°C** and under continuous vibration.

Optional Conformal Coating:A vehicle-spec conformal coating is available for protection against moisture, oil, and contaminants commonly found near tailgates, enhancing long-term reliability and insulation.

Conclusion

LTPCBA’s Automotive Motor PCBA sets a new standard for core control modules in the power tailgate aftermarket through its automotive-grade functionality, scenario-specific adaptation, optimized layout, and robust manufacturing. As a trusted PCBA manufacturer, LTPCBA will continue to advance in the automotive electronics sector, offering more **reliable, smart, and efficient** core component solutions that support the ongoing quality upgrade of vehicle intelligence and aftermarket ecosystems.

Do you have any questions, or would you like to speak directly with a representative?