Contact

Write to Us And We Would Be Happy to Advise You.

Do you have any questions, or would you like to speak directly with a representative?

By 管理

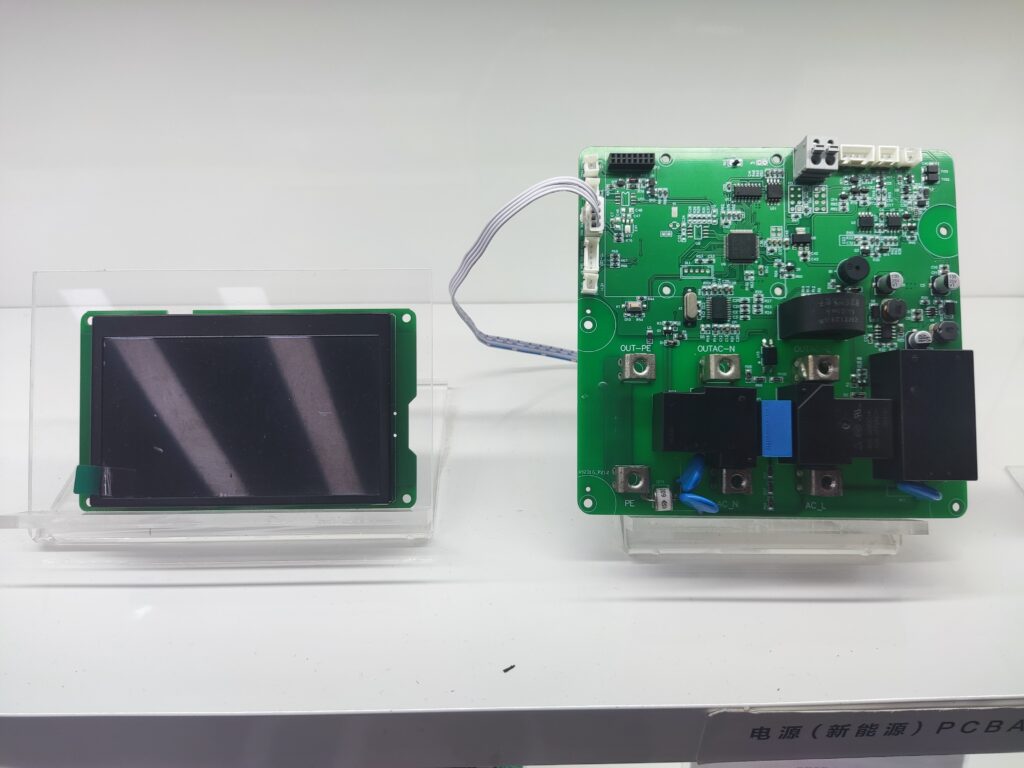

As new energy vehicles become increasingly popular, the performance and reliability of their core charging technology – the PCBA (Printed Circuit Board Assembly) – are more critical than ever. LTPCBA, a professional manufacturer deeply rooted in the industry, offers a wall-mount charging PCBA solution that stands as the core power source for home and underground garage charging units. Our expertise in precise functional definition, meticulous design, and robust manufacturing processes ensures superior performance.

1. Comprehensive Functionality for Precise Scenario Adaptation

Designed around the core principles of “Safety, Efficiency, and Intelligence,” this PCBA delivers multi-dimensional functionality:

*Wide Voltage Compatibility & Power Regulation: Supports AC 220V ±20V input, tolerating common household grid fluctuations. The charging power is adjustable from 6A to 32A, intelligently regulating based on the EV battery’s needs to optimize both charging speed and battery lifespan.

Multi-Layer Safety Protection System:Integrated with a high-performance ARM core MCU, the board features comprehensive protection against lightning surges, over-current, over-voltage, under-voltage, overheating, and leakage. This system continuously monitors and responds to anomalies from power input to charging output, minimizing potential risks.

Smart Control & User Interaction:** Supports connectivity to display modules for visualizing charging status, power, and error codes. The underlying logic enables intelligent scheduling, making home charging both “smart” and user-friendly.

This PCBA is specifically engineered for wall-mount charging applications, perfectly suited for home settings (private garages, residential charging walls) and underground parking facilities. Its compact form factor and stable performance make it a reliable cornerstone for the “last mile” of urban EV energy replenishment.

2. Component Layout: Meticulous Design for Performance & Reliability

A superior PCBA is not just about features, but the art of design and layout. This product showcases LTPCBA’s engineering prowess:

Zoned Functional Layout: Power components (e.g., large relays, high-voltage capacitors) are strictly separated from the control signal area (ARM MCU, communication interfaces). This physical isolation reduces electromagnetic interference, ensuring stable high-current transmission and signal integrity.

High-Reliability Component Selection:Critical power components are industrial-grade, rated for high voltage and large currents to ensure stability under continuous full-load operation. The ARM-core chip is chosen for high integration and low power consumption, balancing processing power with energy efficiency.

User-Friendly Interface Design: Standardized connectors are pre-installed for quick connection to displays, external sensors, and the charging gun, simplifying integration for equipment manufacturers and facilitating future maintenance or upgrades.

3. Manufacturing Process: Robust Techniques for Quality Assurance

Guided by the philosophy that “Process Defines Quality,” LTPCBA employs a full-spectrum precision manufacturing system for this PCBA:

High-Precision SMT Assembly:For miniaturized, high-density chips like the ARM core, we utilize fully automated high-speed placement machines and precision stencil printing, controlling placement accuracy within ±0.02mm to ensure reliable soldering.

High-Reliability Soldering for Power Components: For high-current components, a combination of reflow and wave soldering processes is used to enhance the mechanical strength and electrical conductivity of solder joints, preventing issues like cold solder or joint failure under sustained high-current stress.

Conformal Coating & Environmental Resilience: To combat dampness and dust in environments like underground garages, an optional professional conformal coating is applied, significantly boosting the PCBA’s resistance to moisture, dust, and corrosion, thereby extending its service life.

End-to-End Testing & Validation: From incoming materials to final inspection, each PCBA undergoes rigorous testing, including voltage margin tests, power cycle tests, high/low-temperature aging tests, and safety protection verification, ensuring stable operation under complex real-world conditions.

Conclusion

From functional definition and scenario adaptation to design layout and manufacturing, LTPCBA’s New Energy Charging PCBA embodies Technological Innovation + Manufacturing Strength.It provides the core intelligence for wall-mount chargers and, with its inherent focus on safety, efficiency, and reliability, drives quality upgrades in the home EV charging ecosystem. As a dedicated PCBA manufacturer, LTPCBA will continue to advance in the new energy sector, infusing the industry with more hard-value “Engineered in China” solutions through cutting-edge technology and precision manufacturing.

Next: Not Next

Do you have any questions, or would you like to speak directly with a representative?