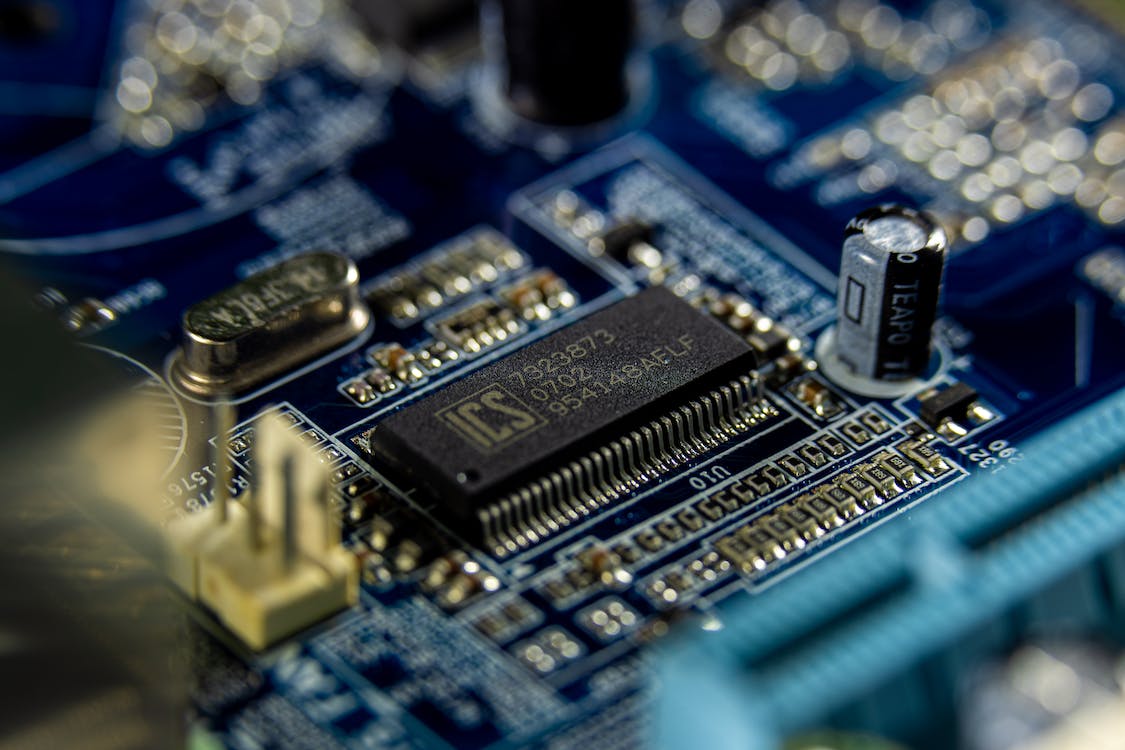

Specialize in HDI, ultra-high layer and any-layer interconnection PCBs. We have mastered the processing of PCBs made from special materials such as ceramics, high-frequency and high-speed materials. For conventional HDI and ultra-high layer PCBs, the fastest delivery time can be 72 hours.

We can take care of the entire process, including manufacturing of Printed Circuit Boards, procurement of components (100% original), PCBA Testing, continuous monitoring of quality and final assembly.

Five DIP assembly production lines, workers with over 10 years of soldering experience, and equipment compatible with PCB boards of various sizes and specifications.

We offer programming, diverse testing services, and a comprehensive quality inspection system. This guarantees that your order not only meets the highest quality standards but also helps you save time and reduce costs.

LTPCBA’s Quick-Turn PCB Assembly Services seamlessly integrate speed, superior quality, and cutting-edge technology. Our services empower businesses to drive innovation at an accelerated pace and streamline production processes, delivering the following key benefits:

Quick-turn Prototyping Service , Start from 1 PCS.

Adhering to strict quality standards and having the technical guarantee of advanced manufacturing equipment。

Partial Components or Full Bom Sourcing Service

Full / Patrial Turn-key with Fast Delivery

In highly competitive sectors such as aerospace, medical devices, and industrial control, where rapid innovation is paramount, our quick-turn services enable companies to bring their products to market faster, gaining a significant competitive edge.

We offer a cost-effective solution for businesses to swiftly validate their PCB designs. This allows you to identify and rectify any potential issues early on, reducing the risk of costly errors during full-scale production.

Includes Automated Optical Inspection (AOI), X-ray, and functional testing to prevent defects.

The automated solder paste printer + SPI combination achieves 0.3mm ultra-fine pitch printing with ±15μm@3σ accuracy via full-automatic vision alignment and pressure control. SPI performs real-time 3D inspection of paste thickness/volume/offset with ≤15μm precision, reducing defects by 85% for optimized SMT process yield.

Jingtuo JTR-1000 Reflow Oven features 10-zone lead-free design with ±1℃ temperature control accuracy. Dual-track system boosts efficiency, accommodating substrates from W50-550mm. Multi-layer insulation ensures precision for delicate metal soldering.

Yamaha YSM10 Pick-and-Place Machine features a new-generation servo system with a placement speed of 46,000 CPH. Its high-speed universal placement head handles components from ultra-small 0.3×0.15mm to large 55×100mm, with a new scanning camera enhancing component handling capabilities.

SMT First Article Inspection Machine uses AI vision + flying probe technology to automatically compare BOM with PCB within 3 minutes, measuring components (resistors, capacitors, etc.) and making intelligent judgments. Supports CAD coordinate import, auto-generates inspection reports, replaces manual inspection with 70% efficiency boost and <0.1% error rate, ensuring batch production consistency.

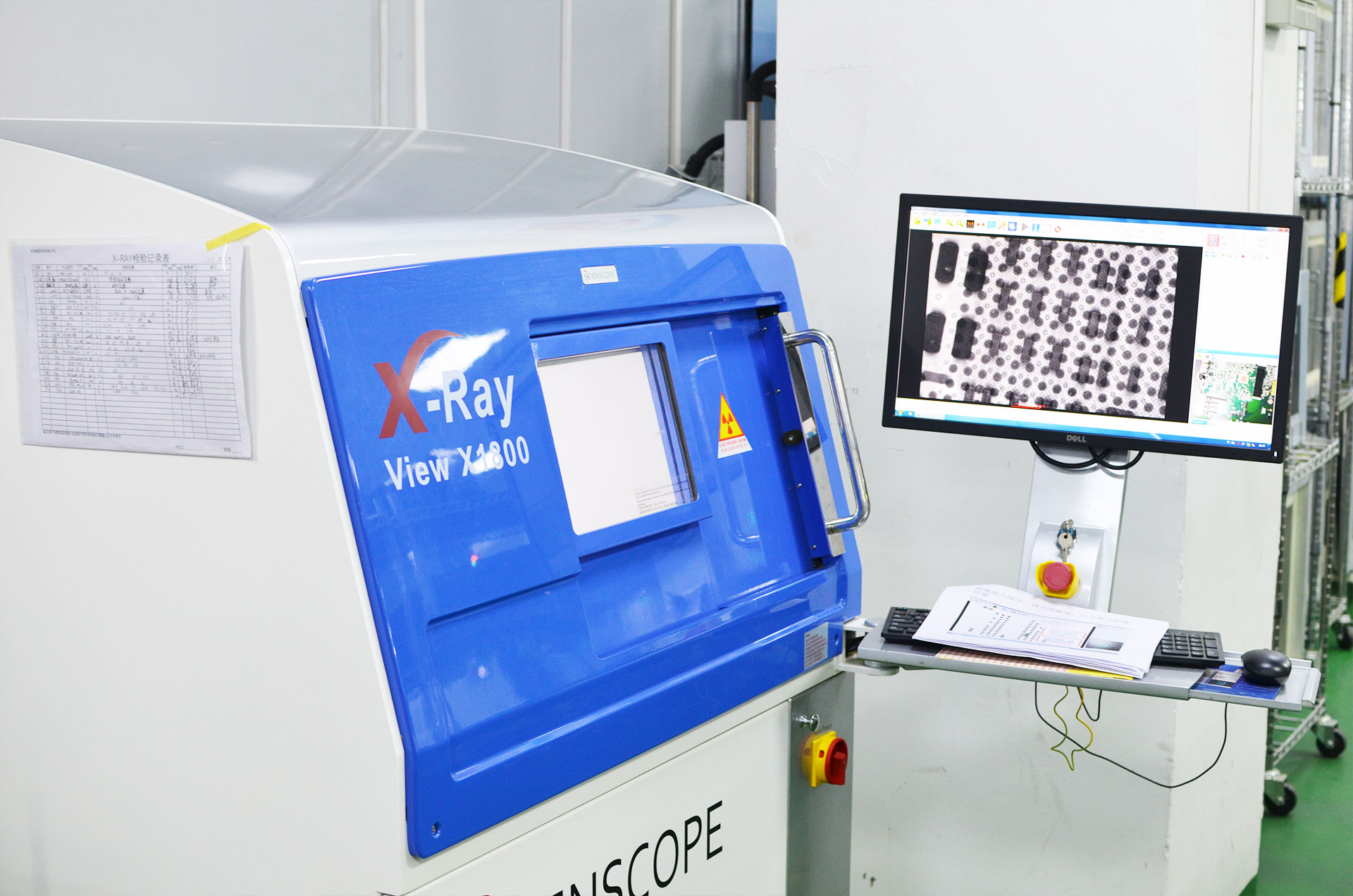

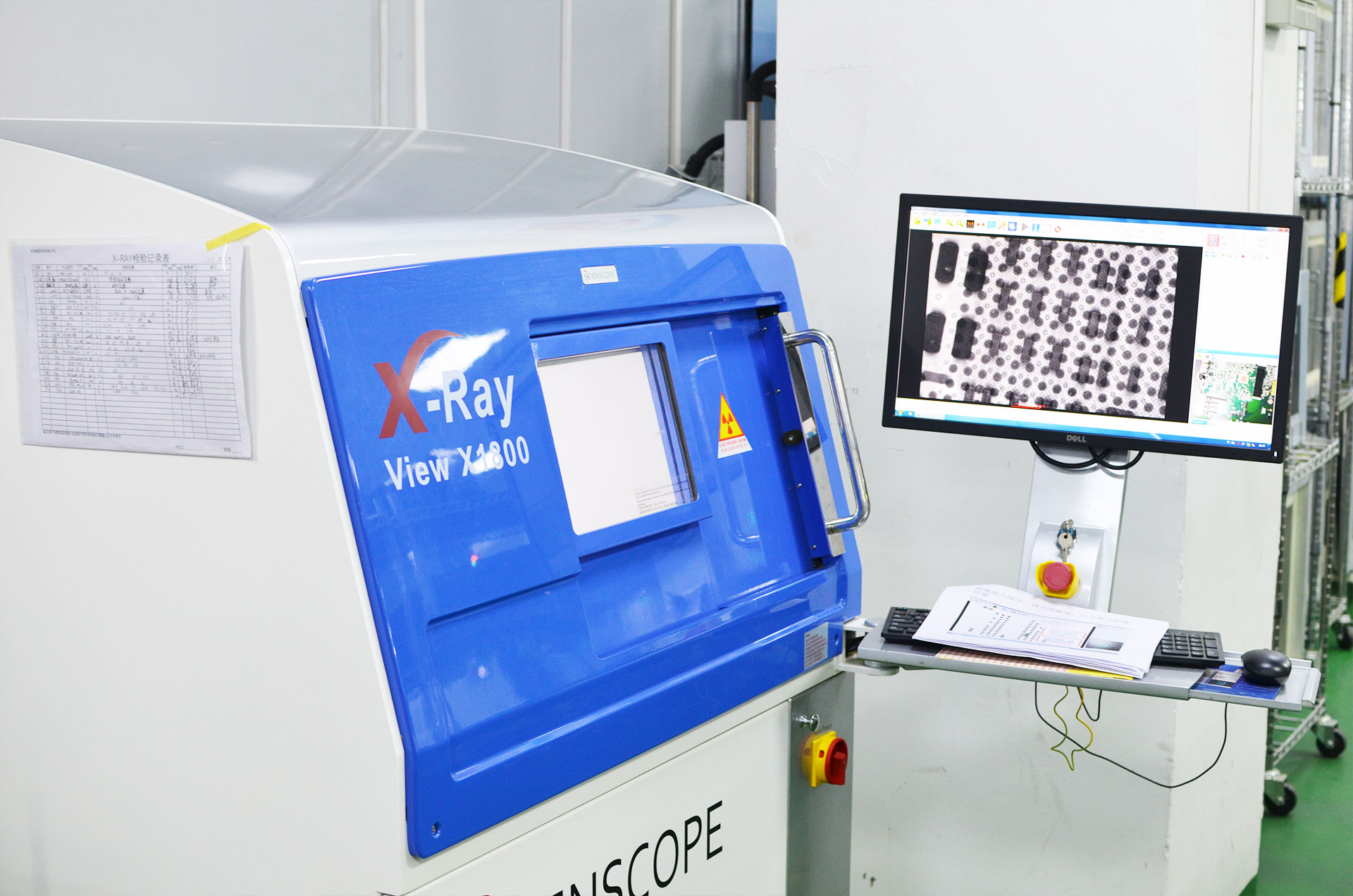

SMT X-Ray inspection system uses micro-focus X-ray technology to penetrate multi-layer PCBs, detecting internal solder joint defects like voids and bridging. With high-resolution imaging (micron-level), it supports 3D tomography for rapid hidden defect localization, enhancing quality control of complex assemblies.

DIP production line is specialized for through-hole component assembly, covering insertion, soldering, and inspection. Featuring chain/rotary conveyance, it accommodates various PCB sizes. Auto-insertion machines achieve 2,000-4,000 cph, with wave soldering ensuring joint reliability for power supplies, appliances requiring high voltage resistance.

We firmly believe the best manufacturing , inspection and test equipments is a top way to ensure the best quality.

By employing these advanced testing methods, we ensure that our PCBs and PCBAs meet the highest standards of quality and reliability before they reach our customers.

Flying probe testing, Fixture test, Impedance test, AOI, Leakage, Solderability, High pot test, Peel test, Microsection analysis, Resistance, Continuity test, PCB coating evaluation …

AOI, X-ray, In-circuit testing (ICT/Bed of nails), Functional testing (FCT), Burn-in Testing:, Fatigue Test, Aging Test …

LTPCBA has amassed extensive experience through countless projects across diverse industries, positioning us as a leading provider of high-precision PCB assembly solutions. Tailored meticulously to the exacting and unique demands of high-tech, mission-critical sectors, our services are trusted by businesses worldwide.

Spanning a vast array of industries, from aerospace and defense, where safety and reliability are non-negotiable, to medical devices that require stringent precision for patient well-being, robotics that demand seamless integration of complex circuitry, and advanced automotive technologies driving the future of mobility. Our expertise also extends to industrial control, where we’ve successfully assembled PCBs for a wide range of applications, including programmable logic controllers (PLCs), motor control systems, and factory automation equipment. In addition, we’ve worked on projects related to next-generation semiconductor innovations, industrial automation, and Unmanned Aerial Vehicle (UAV) technology.

Regardless of the industry or application, our PCB assembly solutions ensure exceptional reliability, top-notch performance, and strict compliance with industry standards. We understand that in these rapidly evolving fields, speed, precision, and scalability are key. That’s why we’re committed to providing the high-quality services needed to accelerate your innovation and production processes, helping you stay ahead in the competitive market.

TESTIMONIALS