CONTENTS

- Key Takeaways

- What Does a Full Turn-Key PCB Manufacturer Offer?

- How Turnkey PCB Assembly Differs from Other Approaches

- Benefits of Choosing a Full Turn-Key PCB Manufacturer

- Steps to Begin with Turnkey PCB Assembly

- FAQ

Key Takeaways

- Full turn-key PCB manufacturing covers design, component sourcing, assembly, testing, and delivery under one roof.

- Streamlines production, reducing lead times by 60% compared to traditional methods.

- Enables cost savings through bulk purchasing and minimized rework, with defect rates as low as 2%.

- Single-point communication and rigorous quality control ensure consistent reliability and faster time-to-market.

What Does a Full Turn-Key PCB Manufacturer Offer?

PCB Design and Prototyping

- Expert design support to translate concepts into functional PCBs.

- Prototyping to validate designs before mass production, reducing errors.

Quality Assurance Steps:

| Evidence Type | Description |

| Data Collection | Monitor critical dimensions post-production |

| Process Capability Studies | Analyze tool wear and operator impact |

| Continuous Improvement | Refine tolerances with manufacturing feedback |

Component Sourcing and Procurement

- End-to-end component procurement from trusted suppliers.

- Digital supply chain management to avoid delays and ensure quality.

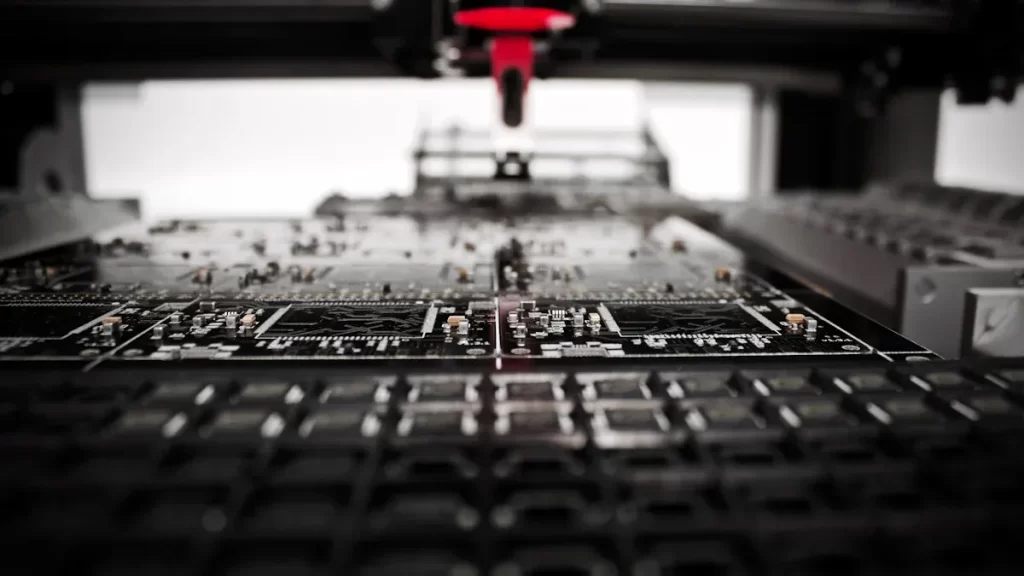

PCB Fabrication and Assembly

- Integrated fabrication and assembly under one facility for seamless workflow.

- Advanced techniques ensuring high first-pass yields (95–98%).

Turnkey vs. Traditional Processes:

| Aspect | Turnkey PCB Assembly | Traditional Separated Processes |

| Lead Times | Shorter (4–5 weeks) | Longer (10–12 weeks) |

| Design Revisions | Faster iteration | Delayed by vendor handoffs |

| Scalability | Smooth transition from prototyping to mass production | Requires new vendor onboarding |

Testing and Quality Assurance

- In-circuit testing, functional testing, and optical inspection.

- Performance metrics:

| Metric | Value Range |

| Order Fulfillment Rate | 90–98% |

| Scrap Rate | 2–5% |

| First Pass Yield (FPY) | 95–98% |

Packaging and Delivery

- Anti-static and shock-resistant packaging.

- Delivery performance benchmarks:

| Metric | Industry Benchmark |

| On-Time Delivery Rate | 90–98% |

| Customer Satisfaction | 70–90% |

How Turnkey PCB Assembly Differs from Other Approaches

Full Turn-Key vs. Partial Turn-Key

| Aspect | Partial Turn-Key | Full Turn-Key |

| Responsibility | Client supplies components | Manufacturer handles all |

| Control | Higher client involvement | Minimal client coordination |

| Advantages | Flexibility in component choice | Streamlined end-to-end process |

Full Turn-Key vs. Contract Manufacturing

| Aspect | Turnkey PCB Assembly | Contract Manufacturing |

| Lead Times | Shorter, unified workflow | Delayed by vendor logistics |

| Quality Consistency | Uniform standards | Inconsistent across vendors |

| Accountability | Single-vendor responsibility | Split accountability |

Benefits of Choosing a Full Turn-Key PCB Manufacturer

Cost Efficiency

- Bulk component pricing reduces material costs (e.g., 23% savings for TechInnovate).

- Eliminates repeat processes and transportation fees.

Simplified Communication

- Single point of contact reduces miscommunication.

- Streamlined coordination from design to delivery.

Faster Production Timelines

- Concurrent design, sourcing, and assembly shorten cycles.

- Prototype-to-production acceleration for quick market entry.

Superior Quality Control

- Design for Manufacturability (DFM) and in-process reviews.

- Quality metrics:

| Metric | Turnkey PCB | Traditional PCB |

| First Pass Yield | 95–98% | 98–99% |

| Defects Per Million | 500–1000 | 50–500 |

Steps to Begin with Turnkey PCB Assembly

Selecting a Manufacturer

| Criteria | Description |

| Manufacturing Expertise | Handle complex designs and reliability needs |

| Material Quality | Certifications for performance materials |

| Production Capacity | Scale from prototyping to mass production |

Submitting Design Documentation

- Provide Bill of Materials (BOM), Gerber files, and testing specifications.

- Documentation hierarchy:

| Type | Purpose |

| Design Inputs | Define device requirements |

| Design Outputs | Approved schematics and layouts |

| Verification | Ensure outputs meet inputs |

Prototyping and Production Approval

- Prototype testing to identify design flaws.

- Advanced Product Quality Planning (APQP) steps:

| APQP Outputs | PPAP Elements |

| Test Production Run | Part Submission Warrant (PSW) |

| Validation Testing | Design FMEA (DFMEA) |

Production Tracking and Delivery

- Key performance indicators:

| KPI Name | Industry Average |

| Production Cycle Time | 12 hours |

| On-Time Delivery | 97% |

FAQ

- What’s the difference between full and partial turn-key?Full turn-key handles all processes, while partial requires client-supplied components.

- How long does full turn-key manufacturing take?Typically 4–5 weeks, 60% faster than traditional methods.

- Can designs be revised after submission?Yes, revisions are possible during the prototyping phase.

- Are turn-key services cost-effective?Yes—bulk purchasing and streamlined processes reduce overall costs.

- What quality tests are included?In-circuit testing, functional testing, and automated optical inspection (AOI).