News

All Tags

- All Tags

- Advanced PCB

- Backlit Membrane Switch

- BGA PCB

- Circuit Board Assembly

- company

- customized

- Design for Manufacturing Analysis

- design for manufacturing and assembly

- Double-layered PCBs

- Electronic Board Repair Service

- FPCs

- Graphic Overlay

- Graphic Overlay Panel

- how much does a PCB assembly cost

- How much to charge for PCB assembly?

- How PCB manufacturing process

- how to estimate PCB assembly

- how to improve PCB assembly process

- how to order PCB assembly

- how to quote PCB

- How to start a PCB manufacturing business

- Integrated Circuit programming

- JLC PCB Assembly

- Membrane keypad

- Membrane Panel

- Membrane Switch

- Membrane Switch Panel

- Metal core PCB

- Mil Spec Pcb

- PCB Assembly Bay Area

- PCB assembly quotes

- PCB Assembly Testing Service

- PCB components

- PCB design for manufacturer

- PCB Fabrication

- PCB manufacturing Europe

- PCB rework services

- PCB turnkey assembly

- Printed Circuit Board Assembly

- Printed circuit board news

- Products

- prototype assembly

- SMT PCB

- stencil PCB

- Tips & Tricks

- What is 4 Layers Hdi Rigid-flex Pcb

- What Is a 5g Pcb Board

- What is a PCB main assembly

- what is consigned PCB assembly

- what is PCB board assembly

- What is the PCB assembly process?

- why is PCB assembly so expensive?

- X-ray PCB

-

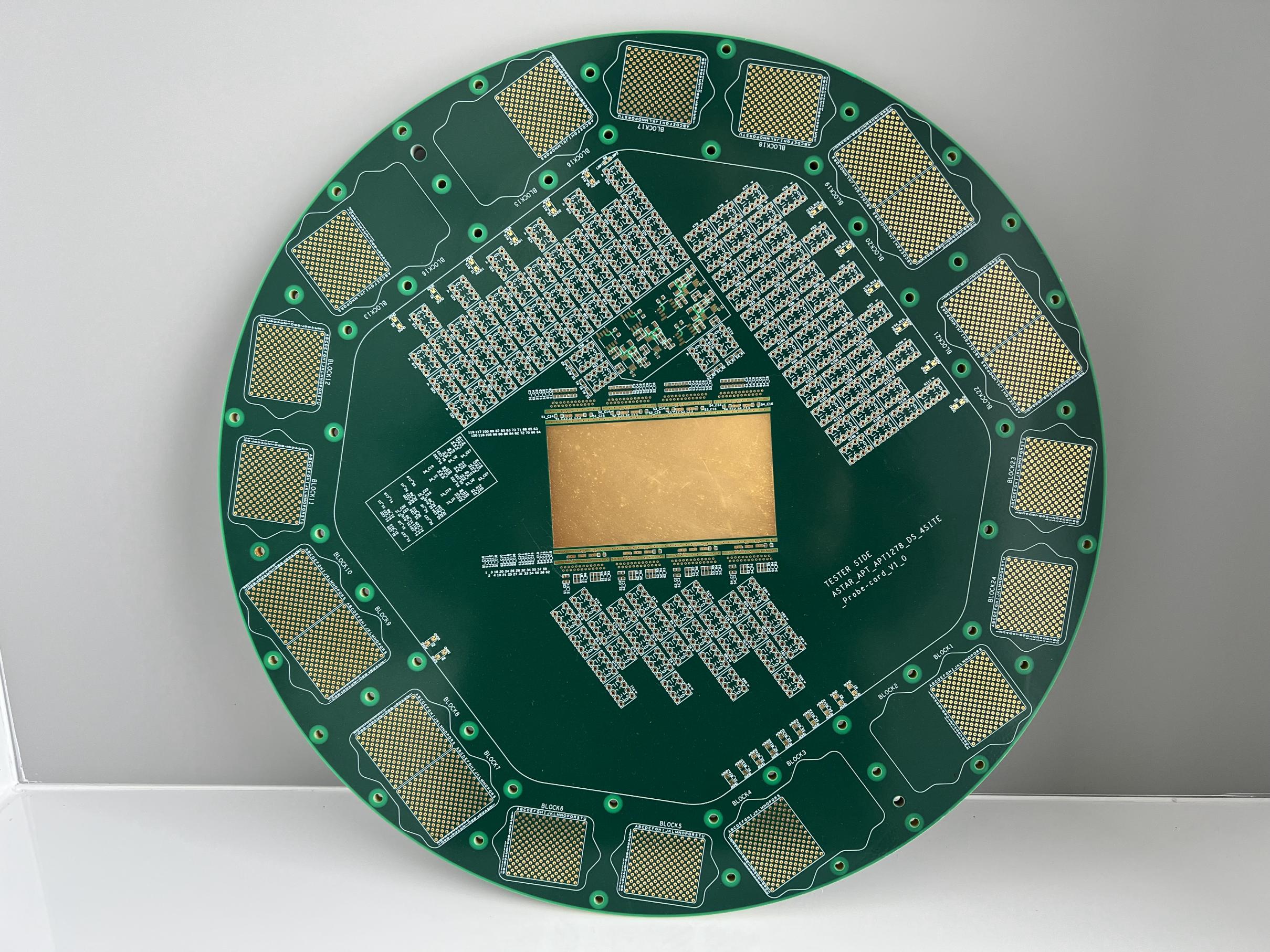

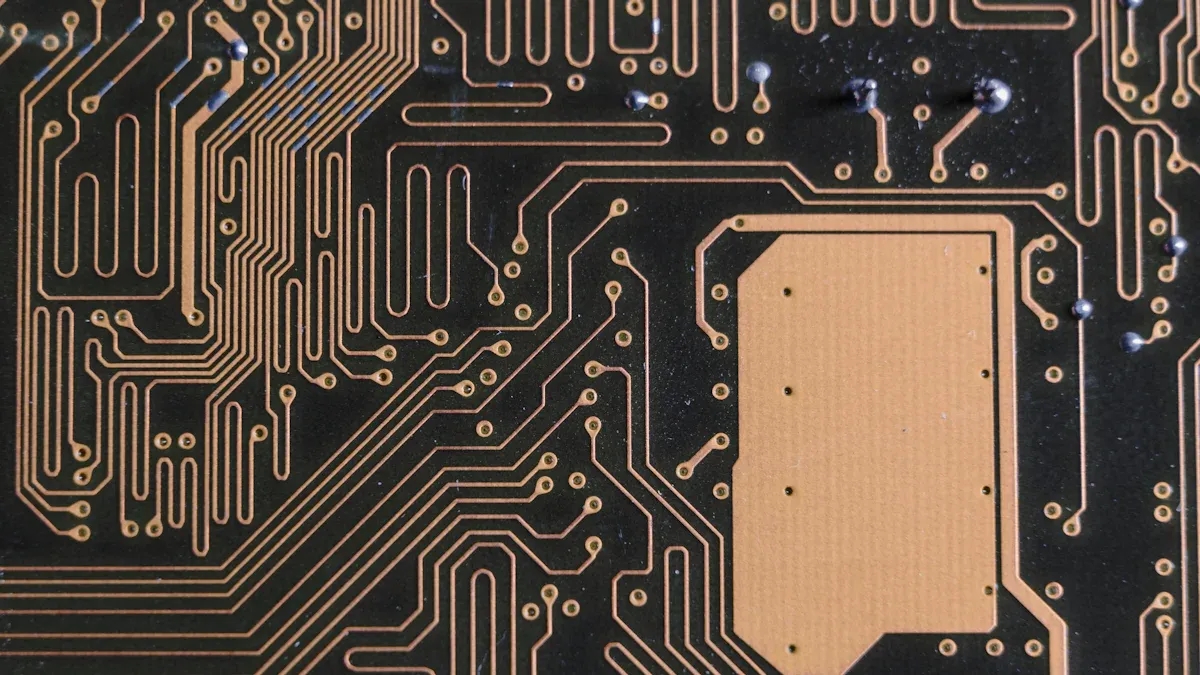

What Kind of PCB Fits ATE Challenges?

05 Dec, 2025

Automated test machines require specific circuit boards that are precise and reliable. When considering what kind of PCB is required for the Automated Test Equipment (ATE), challenges include keeping signals clear, managing heat, and ensuring fast operation. Reports indicate more issues such as fitting different designs, testing new packages, and adhering to quality regulations. LTPCBA addresses these… Continue reading What Kind of PCB Fits ATE Challenges?

Learn More -

What is Back Drilling in HDI PCB Manufacturing?

05 Dec, 2025

Back drilling in HDI PCB manufacturing involves the removal of extra via parts, which helps maintain signal clarity by preventing distortions and echoes. This process of HDI PCB back drill reduces crosstalk and enhances the performance of high-speed circuits. LTPCBA excels in providing back drill solutions, ensuring accuracy and reliability for advanced applications. Key Takeaways # Back drilling takes out extra via… Continue reading What is Back Drilling in HDI PCB Manufacturing?

Learn More -

The differences between spray solder mask and screen solder mask for PCB boards

05 Dec, 2025

A solder mask is a layer that protects a PCB. It keeps copper parts safe from rust and short circuits. Spray solder mask is sprayed evenly on the board. Screen solder mask uses a stencil to put it on. Picking the right method helps your PCB work well and last longer. Key Takeaways # Spray… Continue reading The differences between spray solder mask and screen solder mask for PCB boards

Learn More -

10 Tips to Cut Costs in Custom PCB Production

04 Dec, 2025

Cost-saving is very important in making custom PCBs. Cutting costs while keeping good quality helps your project succeed. Making many boards at once lowers the cost per board. Using both sides of a board costs more money. LTPCBA makes great PCBs and helps improve production steps. Check out these 10 tips to save money and get better results.… Continue reading 10 Tips to Cut Costs in Custom PCB Production

Learn More -

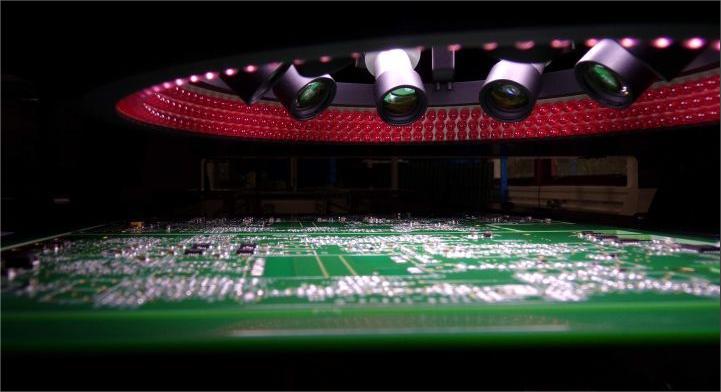

The Essential Steps in Fast Turnkey PCB Assembly

04 Dec, 2025

Fast turnkey PCB assembly is important in making electronics today. It helps with speed, reliability, and saving money, which are key to staying competitive. These services simplify design, buying parts, assembly, and testing. This means products are ready faster and take less time to develop. Automated Optical Inspection (AOI) finds mistakes with 99.5% accuracy. This improves production… Continue reading The Essential Steps in Fast Turnkey PCB Assembly

Learn More -

LTPCBA TVS Protection Board: Robust Defense Against Transient Surges with Customizable Component Integration

04 Dec, 2025

As a professional PCBA manufacturer, LTPCBA introduces this TVS (Transient Voltage Suppression) protection bare PCB board, featuring modular panel design and highly compatible pad layouts to serve as a core hardware platform for transient surge protection in electronic devices. 1. Technical Features: Engineered for Surge Protection Reliability – Panelized Design & Standardized Units Multi-unit panel… Continue reading LTPCBA TVS Protection Board: Robust Defense Against Transient Surges with Customizable Component Integration

Learn More